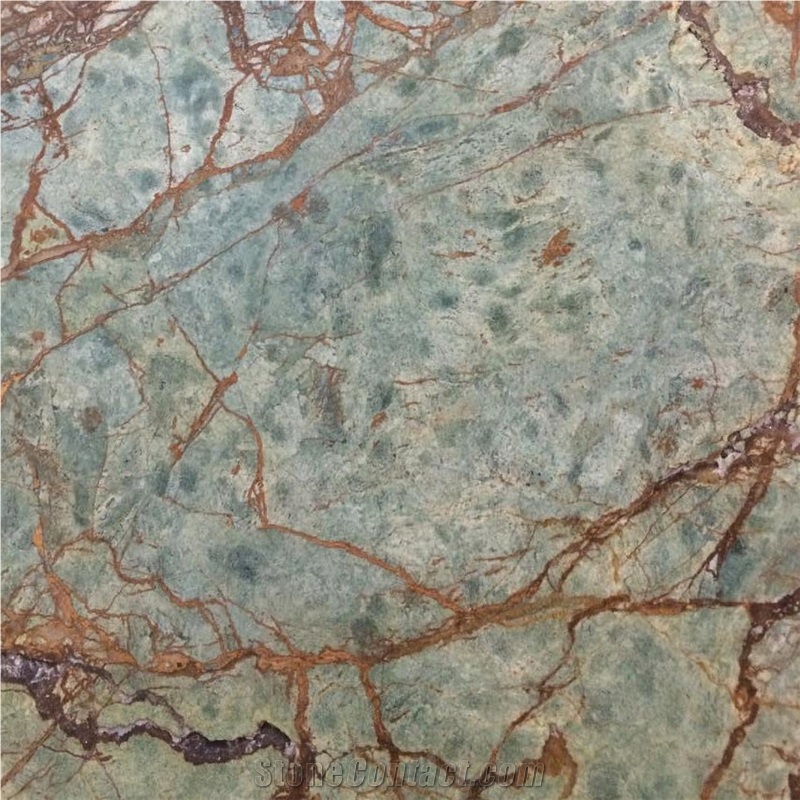

Turquoise Granite

Iran

(Khorasan, Mashhad)

Iran

(Khorasan, Mashhad)

Turquoise Granite is a vibrant and vivid color that is often associated with the gemstone turquoise, known for its striking blue-green hues that originates from quarries in Iran.

Granite itself is primarily composed of minerals such as quartz, feldspar, and mica, which contribute to its characteristic speckled and veined appearance. If a granite variety displays a turquoise blue color, it would likely be due to the presence of specific mineral compositions or pigmentation within the stone.

Turquoise Granite from Iran, is commonly used for a variety of applications, including countertops, flooring, wall cladding, and architectural features. It is renowned for its resistance to scratches, heat, and stains when properly sealed and maintained.

What type of cutting blade should I use to cut 2cm thick Turquoise Granite?

What grade is Iran's Turquoise Granite?

Can Turquoise Granite be used as a kitchen cutting board?

Is Iran's Turquoise Granite an expensive stone?

What thickness of Turquoise Granite backsplash tiles would be better?

What are the extraction methods for Turquoise Granite?

How thick is Iran's Turquoise Granite slabs?

Can Iran's Turquoise Granite be used exterior applications in very sunny climates?

Can Iran's Turquoise Granite be used in a living room?

Does Turquoise Granite countertop scratch easily?

Is Turquoise Granite durable for use as outdoor patio pavers?

What is the coefficient of friction of Leathered Iran's Turquoise Granite tiles?

Can Turquoise Granite be used for airport floor covering?

Can Iran's Turquoise Granite be used in landscaping?

What thickness of Turquoise Granite bathroom countertop would be better?

Is Turquoise Granite durable for use as urban walkway pavers?

What type of abrasive should I use to polish the Turquoise Granite floor surface?

For Turquoise Granite wet area floor application, which surface treatment should be chosen?

Are there color variations of Iran's Turquoise Granite?

How should I clean Turquoise Granite kitchen countertop?

Can Turquoise Granite be used for swimming pool terrace?

What machinery is needed for Turquoise Granite quarrying?

Jim****

Reviewed in United States on Aug 08,2022

Jim****

Reviewed in United States on Aug 08,2022

Is this sold in the US? How can I receive a sample?

-

Xiamen Landiview Stone Co. Ltd.

China

China

8YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

8YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

-

-

Iran

Iran

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

Iran

Iran

10YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

10YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

Xiamen Fancies Industrial Co., Ltd

China

China

1YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

1YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

-

Xiamen Fancies Industrial Co., Ltd

China

China

1YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

1YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

-

-

Xiamen Asian Stone Imp.& Exp. Co.,Ltd.

China

China

13YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

13YRDiamond members are premium members on platform, providing members with comprehensive approach to promoting their products, increasing products exposure and investment return to maximize.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Verified Supplier is for prove company authenticity,including business license,trade license and effective office space,to enhance buyers' trust to suppliers and their products, reducing communication costs.

Contact Supplier

The request includes: 1. surface finished, size 2. quantity required

Yus***Wrote:

Yus***Wrote:

I would like to purchase Turquoise Granite slabs as shown in the attached image. Could you please provide a price quote and confirm their availability for delivery to Kuwait?

Hea***Wrote:

Hea***Wrote:

I want to buy Turquoise Granite

Isa***Wrote:

Isa***Wrote:

I want to buy Turquoise Granite