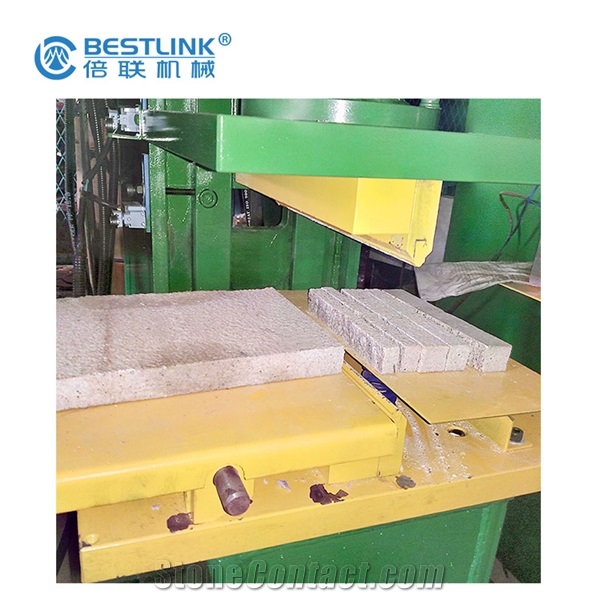

Bestlink hydraulic stone pressing stamping machine

FOB Price:$5000-8000

Parameters |

Unit |

CP90 |

Main motor power |

kw |

7.5 |

Max. processing width |

mm |

8000 |

Approx. Weight |

Kg |

1200 |

Max. processing thickness |

mm |

350 |

Splitting power |

T |

70T |

This hydraulic stone stamping machine is very popular in the world,such as USA,India,United Kingdom,etc...

The hydraulic stamping machine is specially designed for changing the leftovers of slabs or tiles into amazing paving stones. It could stamp more than 40 different shapes by different dies with hydraulic system inside. And we could make special designs according to your requirements. This machine has very compact structure. It is easily operated and maintained. It has the output around 100-120m² per day. The standard splitting power is 20 ton, maximum processing stone size is 30cm×30cm×5cm(L*W*H). We can adjust the hydraulic system with 40tons splitting force, then it can process the slabs up to 8cm in thickness. There are 2 types: CP90 (A) and CP90 (B). CP90 (A) has two functions---- stamping and cutting, while CP90 (B) has one more special device to split the slabs into natural face strip in rapid succession.

Model | CP90-20T | CP90-40T | CP90SA | CP90FA |

Hydraulic pressure (Mpa) | 20 | 20 | 20 | 20 |

Splitting power (T) | 20 | 40 | 40 | 40 |

Electric motor power (kw ) | 3.7 | 5.5 | 5.5 | 9 |

Max.slab stamping size (cm) | 30*30*3 | 30*30*5 | 30*30*5 | 30*30*5 |

Max splitting length (cm) | 30 | 35 | Semi-automatic | Fully-automatic |

Slab thickness (cm) | 1-3 | 1-5 | 1-5 | 1-5 |

Machine size (cm) | 80*100*150 | 80*100*150 | 80*100*150 | 230*95*185 |

Weight (kg) | 500 | 580 | 650 | 1500 |

Fuctions | stamping,cutting, | stamping,cutting, | stamping | stamping,air |

7YR

7YR

Richard Chen

Richard Chen