Pedrini Resinline Stone Drying, Catalysing Oven for Marble and Granite Slabs

FOB Price:

Type:

Stone Factory MachinesResin Line MachinesStone Drying, Catalysing Oven

Usage:

Granite, Marble, Limestone, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Remote troubleshooting, Field troubleshooting

You may also like

Machinery Function Features

A deep material drying before the resin application is fundamental.

The process requires about 20-40 minutes to dry interior moisture according to the type of material and the set temperature.

Drying and pre-heating oven must have a dual action: dry moisture from the slabs and then heat them up to the suitable temperature for resining (40÷45°C).

Resinline plants use two types of ovens for the material drying and pre-heating:

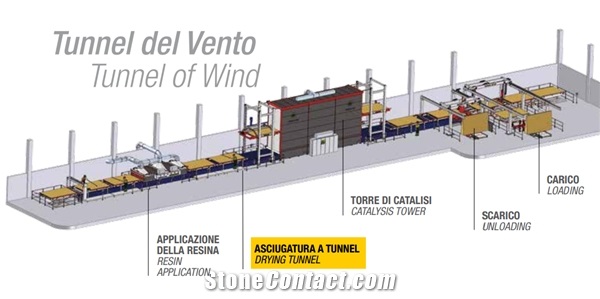

. Tunnel of Wind, exclusive tunnel system.

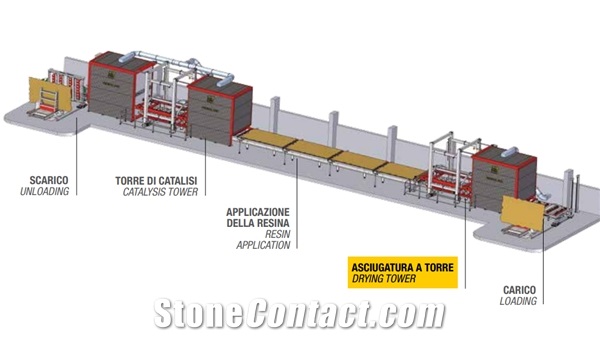

. Drying Towers, multilevel ovens.

They both include the warm air recirculation.

The longitudinal tunnel drying system is composed of an insulated gallery with insulating panels, where the slabs enter from one side and exit from the opposite side.

The tunnel length is determined according to the quantity of slabs to be processed.

The warm air flows opposite to the material direction, heats the slab so that the moisture is first moved away and then totally dried during its passage into a heating exchanger, properly placed outside the tunnel.

The supports with the slabs move along the tunnel through a horizontal chain handling system, while two elevators placed at both ends transfer them upstairs.

The heating unit can be powered electrically, by methane or by LPG.

The process requires about 20-40 minutes to dry interior moisture according to the type of material and the set temperature.

Drying and pre-heating oven must have a dual action: dry moisture from the slabs and then heat them up to the suitable temperature for resining (40÷45°C).

Resinline plants use two types of ovens for the material drying and pre-heating:

. Tunnel of Wind, exclusive tunnel system.

. Drying Towers, multilevel ovens.

They both include the warm air recirculation.

The longitudinal tunnel drying system is composed of an insulated gallery with insulating panels, where the slabs enter from one side and exit from the opposite side.

The tunnel length is determined according to the quantity of slabs to be processed.

The warm air flows opposite to the material direction, heats the slab so that the moisture is first moved away and then totally dried during its passage into a heating exchanger, properly placed outside the tunnel.

The supports with the slabs move along the tunnel through a horizontal chain handling system, while two elevators placed at both ends transfer them upstairs.

The heating unit can be powered electrically, by methane or by LPG.

Recommended Stone Drying, Catalysing Oven Products

Related Products:

Giambattista Pedrini

Giambattista Pedrini