Home ProductsStone MachineryStone Factory MachinesResin Line MachinesRobotic Unit for Resin Treatment

Resin Coating Anthropomorphic Robot Galileo - Smart Resin Coating Robotic System

FOB Price:

Type:

Stone Factory MachinesResin Line MachinesRobotic Unit for Resin Treatment

Usage:

Granite, Marble, Limestone, Onyx, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Remote troubleshooting

Machinery Function Features

The production capacity our plants varies from a less of 6 slabs/h to a maximum of 70 slabs/h.

The level of automation of the plant line depends on Customer’s requirements, whereas the heating systems of drying and catalysis machineries can be equipped with gas or electrical devices.

The plants features are not pre settled, therefore each line is designed according to the Customer’s demands that is about the useful space in the company the needed production capacity and the material characteristics.

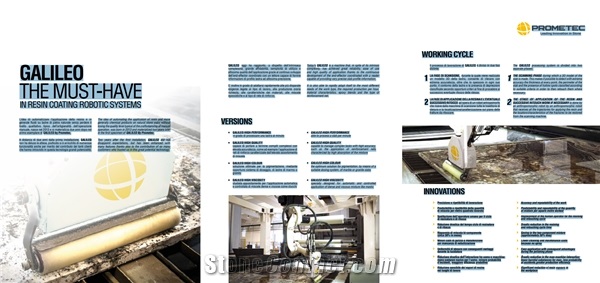

The idea of automating the application of resin and more generally chemical products on natural stone slabs without losing the quality level typical of the craftsmanship of manual

operation, was born in 2013 and materialized two years later in the first specimen of GALILEO By Prometec.

Two years after the first installation, GALILEO did not disappoint expectations, but has been enhanced with many features thanks also to the contribution of so many customers who trusted us in this great potential technology.

Today’s GALILEO is a machine that, in spite of its intrinsic complexity, has achieved great reliability, ease of use and high quality of application thanks to the continuous development of the end-effector coordinated with a reader capable of providing very precise slab profile information.

It is also able to rapidly adapt itself to the most different needs of the work type, the required production per hour, material characteristics, epoxy blends and the type of reinforcement net.

VERSIONS

* GALILEO HIGH PERFORMANCE

able to process a slab per minute

• GALILEO HIGH QUALITY

capable to manage complex tasks with high accuracy, such as the application of reinforcement nets characterized by high absorption of the mixture

• GALILEO HIGH COLOUR

the optimum solution for pigmentation, by means of a suitable dosing system, of marble or granite slabs

• GALILEO HIGH VISCOSITY

specially designed for automatic and controlled application of dense and viscous mixture like mastic

WORKING CYCLE

The GALILEO processing system is divided into two

separate phases:

1. THE SCANNING PHASE during which a 3D model of the slab is made. This makes it possible to detect with extreme accuracy the thickness at every point, the perimeter of the slab and the presence of hollow spots classified according to suitable criteria in order to then retouch them where necessary.

2. THE STAGE OF APPLICATION OF THE RESIN AND SUCCESSIVE RITOUCH WORK IF NECESSARY is done by an anthropomorphic robot by an anthropomorphic robot that receives all the trajectories for applying the resin and the location/characteristics of the fractures to be restored from the scanning machine.

INNOVATIONS

Accuracy and repeatability of the work

Predictability and repeatability of the quantity of mixture per square metre worked

Replacement of the human operator for the resining and retouching cycle

Drastic reduction in the resining and retouching cycle time

Saving in the two-component mixture (approximately 30% less)

Lower cleaning and maintenance costs because no spray

Even application with consequent advantages during the polishing phase

Drastic reduction in the man-machine interaction:

fewer harmful substances for man, less probability of accidents,greater production efficiency

Significant reduction of resin vapours in the workplace

The level of automation of the plant line depends on Customer’s requirements, whereas the heating systems of drying and catalysis machineries can be equipped with gas or electrical devices.

The plants features are not pre settled, therefore each line is designed according to the Customer’s demands that is about the useful space in the company the needed production capacity and the material characteristics.

The idea of automating the application of resin and more generally chemical products on natural stone slabs without losing the quality level typical of the craftsmanship of manual

operation, was born in 2013 and materialized two years later in the first specimen of GALILEO By Prometec.

Two years after the first installation, GALILEO did not disappoint expectations, but has been enhanced with many features thanks also to the contribution of so many customers who trusted us in this great potential technology.

Today’s GALILEO is a machine that, in spite of its intrinsic complexity, has achieved great reliability, ease of use and high quality of application thanks to the continuous development of the end-effector coordinated with a reader capable of providing very precise slab profile information.

It is also able to rapidly adapt itself to the most different needs of the work type, the required production per hour, material characteristics, epoxy blends and the type of reinforcement net.

VERSIONS

* GALILEO HIGH PERFORMANCE

able to process a slab per minute

• GALILEO HIGH QUALITY

capable to manage complex tasks with high accuracy, such as the application of reinforcement nets characterized by high absorption of the mixture

• GALILEO HIGH COLOUR

the optimum solution for pigmentation, by means of a suitable dosing system, of marble or granite slabs

• GALILEO HIGH VISCOSITY

specially designed for automatic and controlled application of dense and viscous mixture like mastic

WORKING CYCLE

The GALILEO processing system is divided into two

separate phases:

1. THE SCANNING PHASE during which a 3D model of the slab is made. This makes it possible to detect with extreme accuracy the thickness at every point, the perimeter of the slab and the presence of hollow spots classified according to suitable criteria in order to then retouch them where necessary.

2. THE STAGE OF APPLICATION OF THE RESIN AND SUCCESSIVE RITOUCH WORK IF NECESSARY is done by an anthropomorphic robot by an anthropomorphic robot that receives all the trajectories for applying the resin and the location/characteristics of the fractures to be restored from the scanning machine.

INNOVATIONS

Accuracy and repeatability of the work

Predictability and repeatability of the quantity of mixture per square metre worked

Replacement of the human operator for the resining and retouching cycle

Drastic reduction in the resining and retouching cycle time

Saving in the two-component mixture (approximately 30% less)

Lower cleaning and maintenance costs because no spray

Even application with consequent advantages during the polishing phase

Drastic reduction in the man-machine interaction:

fewer harmful substances for man, less probability of accidents,greater production efficiency

Significant reduction of resin vapours in the workplace

Related Products:

Machinery

Factory Machines

Resin Line Machines

Robotic Unit for Resin Treatment

Granite Robotic Unit for Resin Treatment

Marble Robotic Unit for Resin Treatment

Limestone Robotic Unit for Resin Treatment

Onyx Robotic Unit for Resin Treatment

Basalt Robotic Unit for Resin Treatment

Quartzite Robotic Unit for Resin Treatment

Sandstone Robotic Unit for Resin Treatment

Travertine Robotic Unit for Resin Treatment

Prometec Machines

Carlo Belle

Carlo Belle