Home ProductsStone MachineryStone Factory MachinesStone Surface Processing Machines Slab Polishing Line Machine

SPGE Series Automatic Polishing Machine with Resin Grinding Disc- Slab Polishing Line Machine

FOB Price:$50000-79000

Type:

Stone Factory MachinesStone Surface Processing Machines Slab Polishing Line Machine

Usage:

Granite, Basalt

After-Sale

Lead Time:

35 Days

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

Trade Terms

Delivery Details: FOB,CFR,CIF,EXW,Express Delivery

Payment :

You may also like

Machinery Function Features

1. This machine polish the surface for granite tiles, and is equipped with resin disc polishing heads, the polishing result is more comprehensive, more efficient, lower abrasive wearing.

2. Using PLC system and liquid crystal display screen menu, offering intelligent control.

3. Easy to operate.the stroke pressure when the main spindle lifts and falls, the beam travel speed and the belt moving speed can be adjusted according to the stone materials and the requiring finishing gloss.

4. Auto-dodging function and shape-memory function. equipped with advice to prevent the grinding head from mistakenly hitting the belt, higher automation operation and lower labor the strength.

5. Using the most advanced and high-quality construction, rational structure, high stability and efficiency, and energy-saving operation.

6. Using central automatic lubrication system, so that all moving parts and bearings can get a good lubricating effect and longer life.

7. The power movement of polishing heads uses the narrow V belt with teeth set, to improved slabs flatness, reduced movement consumption and enhances the longer service life.

2. Using PLC system and liquid crystal display screen menu, offering intelligent control.

3. Easy to operate.the stroke pressure when the main spindle lifts and falls, the beam travel speed and the belt moving speed can be adjusted according to the stone materials and the requiring finishing gloss.

4. Auto-dodging function and shape-memory function. equipped with advice to prevent the grinding head from mistakenly hitting the belt, higher automation operation and lower labor the strength.

5. Using the most advanced and high-quality construction, rational structure, high stability and efficiency, and energy-saving operation.

6. Using central automatic lubrication system, so that all moving parts and bearings can get a good lubricating effect and longer life.

7. The power movement of polishing heads uses the narrow V belt with teeth set, to improved slabs flatness, reduced movement consumption and enhances the longer service life.

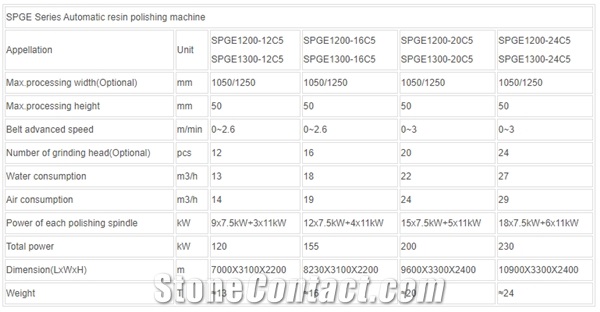

Technical Data

Parameters |

Unit |

SPGE1200-12C |

SPGE1200-16C |

SPGE1200-20C |

SPGE1200-24C |

Compressed air requirement |

m3/h |

14 |

19 |

24 |

29 |

Approx. Weight |

Kg |

≈13 |

≈16 |

≈20 |

≈24 |

Machine overall width |

mm |

3100 |

3100 |

3300 |

3300 |

Power of each dressing unit |

kw |

9*7.5kw+3*11kw |

12*7.5kw+4*11kw |

15*7.5kw+5*11kw |

18*7.5kw+6*11kw |

Conveyor system forward speed |

mm/min |

0-2.6 |

0-2.6 |

0-3 |

0-3 |

Slabs max. processable width |

mm |

1200 |

1200 |

1200 |

1200 |

Machine overall length |

mm |

7000 |

8230 |

9600 |

10900 |

Machine overall height |

mm |

2200 |

2200 |

2400 |

2400 |

Number of polishing heads/honing units |

nr |

12 |

16 |

20 |

24 |

Slabs max. processable thickness |

mm |

50 |

50 |

50 |

50 |

Cooling water requirement |

m3/h |

13 |

18 |

22 |

27 |

Components

Recommended Slab Polishing Line Machine Products

Buyers' Request

Bre***Wrote:

Bre***Wrote:

Hi, I'd like to know the price of the K-Lux Single head polisher please.

4YR

4YR

Franco LIAO

Franco LIAO