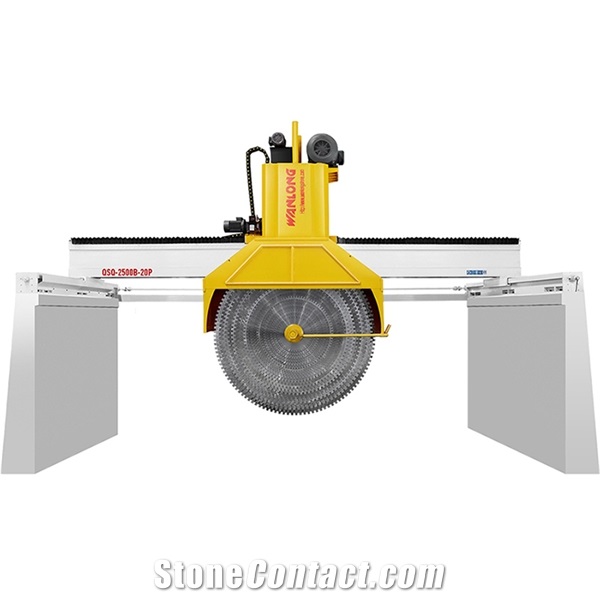

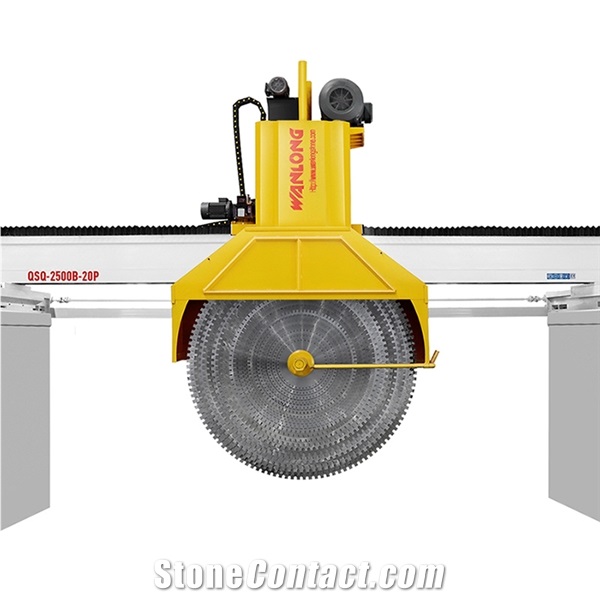

Stone Machinery QSQ-2500-20P Multi-Blade Granite Block Cutting Machine

FOB Price:$52000-55000

ln addition, the multi-layer seal is designed in the guide sleeve, which iswaterproof, dust-proof and Anti-oil-leakage, to improve the service life.The forward & backward slicing are driven by high-precision screw nuts.Automatic slicing, and key parts are using imported high-quality parts.The blocks are placed directly on the ground, which can save the trolleyand its maintenance costs; therefore, it has the advantages of highcutting efficiency, high slicing accuracy, and consistent thickness of thecut slabs, good flatness,high stability, and convenient operation. It isespecially suitable for cutting high value granite and marble blocks.

Parameters |

Unit |

QSQ-2500-20P |

Disc motor power |

kw |

75 |

Approximate Weight |

Kg |

18000 |

Maximum machine width |

mm |

5200 |

Maximum block height |

mm |

1400 |

Maximum disc stroke |

mm |

2000 |

Water consumption |

m³/h |

35 |

Disc diameter |

mm |

2500 |

Machine width |

mm |

5200 |

Maximum block length |

mm |

5300 |

Maximum block width |

mm |

3000 |

Usefull cutting height |

mm |

1400 |

Machine front dimension |

mm |

9500 |

The machine adopts PLC programmable controller and HumanMachine Interaction control,supplemented by ultra-high-precisionrotary encoder for segmentation. The left and right feeding is controlled by inverter.

The cutting method, cutting pieces, cutting thickness, feeding depth andfeeding speed can be set arbitrarily according to different stonematerials. It is using hydraulic lifting for up and down.Combined withchrome-plated guide rod and wear-resistant guide sleeve,so thematching gap is small, and it's wear-resistant and beautiful.

ln addition, the multi-layer seal is designed in the guide sleeve, which iswaterproof, dust-proof and Anti-oil-leakage, to improve the service life.The forward & backward slicing are driven by high-precision screw nuts.Automatic slicing, and key parts are using imported high-quality parts.The blocks are placed directly on the ground, which can save the trolleyand its maintenance costs; therefore, it has the advantages of highcutting efficiency, high slicing accuracy, and consistent thickness of thecut slabs, good flatness,high stability, and convenient operation. It isespecially suitable for cutting high value granite and marble blocks.

1. SIEMENS main motor, 110KW.2. PANASONIC PLC, PANASONIC converter, FUJI contactor3. Encoder for X, Y, Z (left & right, up & down, and forward & backward) movement.4. Crossbeam length 9.5 meter, Side beam length 6 meter5. Equiped locking devices on side beams to avoid crossbeam shifting6. With pulley cover for better protection7. Adopts reductor RV130 for feeding.8. Pillar type hydraulic lifting system.9. Crossbeam size 9500X1200X900mm

guo xuyong

guo xuyong