Home ProductsStone MachineryStone Factory MachinesStone Block Cutting MachinesGiant Disc Bridge Saw Machine

Multi-Blade Bridge Hydraulic Lifting Slicing Block Cutter DF-2500

FOB Price:$20000-38000

Type:

Stone Factory MachinesStone Block Cutting MachinesGiant Disc Bridge Saw Machine

Usage:

Granite, Marble, Limestone, Slate, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Lead Time:

15 Days

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

Trade Terms

Port:

Xiamen Port- China

Delivery Details: FOB,CFR,CIF,EXW

Payment :

More

You may also like

Machinery Function Features

Technical parameters for block cutter:

Technical data

main motor power 37-55kw

total motor power 40-48kw

beam sieze 500*600*7500mm

blade size 1600-2500mm

max vertical stroke 1100mm

max processing length 4000mm

max processing width 2200mm

water consumption 8.5m³/h

machine size and weight 7800*4500*6500mm, 12T

We provide customization product please contact our sales with detail requirement, we will manufacture machine accordingly:

Special customization size:

Cross beam length: 6500-10500mm

Side beam length:4500-8000mm

Features:

The bridge cutting machine is mainly for granite and marble, it adopts multidisc and PLC programmable control and man-machine interface, combined with a super-precision rotary encoder for slicing, uses frequency converter to control left-right feeding and adjusts the speed according to the stone material. It adopts a hydraulic lifting system and forward-backward slicing adopts high-precision screw nut driving, automatic slicing, main spare parts adopt imported good-quality materials. The block can be placed on the ground directly, saving the cost of trolley and maintenance. It is especially suitable for cutting high-value granite and marble block because of high-efficiency cutting rate, high precision slicing, flatness, stability and easy operation.

Production process:

1.Customer need to prepare two sides foundation first with drawing provided by us

2.Install machine and blades

3.Machine cut

4.take down the slab from block one by one, we can make a mould to support the slab, machine can cut directly to the end and slab will not fall apart

5.Trolley is optional according to customers’ requirement

After sales service

We provide skilled and rich experience technician for installation and after-sale service

Machine details:

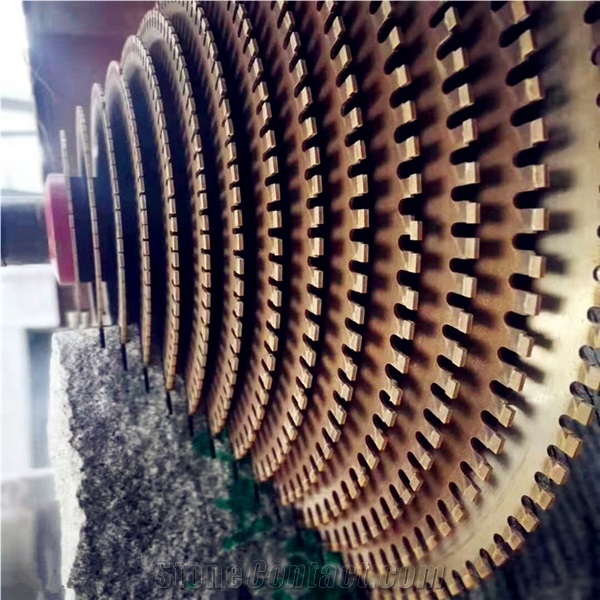

Blade: two ways of blade combination

1.Big-medium-small combination

2.Big-small combination

The Hi-win liner guide is optional as per customer

Packaging & Shipping

The machine will be consolidated tighly and safely within container and deliver by sea or railway, we offer fast delivery and prompt react.

Technical data

main motor power 37-55kw

total motor power 40-48kw

beam sieze 500*600*7500mm

blade size 1600-2500mm

max vertical stroke 1100mm

max processing length 4000mm

max processing width 2200mm

water consumption 8.5m³/h

machine size and weight 7800*4500*6500mm, 12T

We provide customization product please contact our sales with detail requirement, we will manufacture machine accordingly:

Special customization size:

Cross beam length: 6500-10500mm

Side beam length:4500-8000mm

Features:

The bridge cutting machine is mainly for granite and marble, it adopts multidisc and PLC programmable control and man-machine interface, combined with a super-precision rotary encoder for slicing, uses frequency converter to control left-right feeding and adjusts the speed according to the stone material. It adopts a hydraulic lifting system and forward-backward slicing adopts high-precision screw nut driving, automatic slicing, main spare parts adopt imported good-quality materials. The block can be placed on the ground directly, saving the cost of trolley and maintenance. It is especially suitable for cutting high-value granite and marble block because of high-efficiency cutting rate, high precision slicing, flatness, stability and easy operation.

Production process:

1.Customer need to prepare two sides foundation first with drawing provided by us

2.Install machine and blades

3.Machine cut

4.take down the slab from block one by one, we can make a mould to support the slab, machine can cut directly to the end and slab will not fall apart

5.Trolley is optional according to customers’ requirement

After sales service

We provide skilled and rich experience technician for installation and after-sale service

Machine details:

Blade: two ways of blade combination

1.Big-medium-small combination

2.Big-small combination

The Hi-win liner guide is optional as per customer

Packaging & Shipping

The machine will be consolidated tighly and safely within container and deliver by sea or railway, we offer fast delivery and prompt react.

Technical Data

Parameters |

Unit |

DFD-L2500/2800/3000 |

Max. Load Capacity |

26 |

1300 |

Max. block width |

4 |

2000 |

Unloading Units Strips Width |

4 |

2000 |

Installed power |

kw |

42 |

Max. block height |

4 |

2000 |

Machine heigth |

4 |

3300 |

Max. block length |

4 |

4300 |

Approx. Weight |

26 |

13000 |

Video

Operation Video

Screen.PrimaryScreen.Bounds.Height

Related Products:

Machinery

Stone Factory Machines

Stone Block Cutting Machines

Giant Disc Bridge Saw Machine

Granite Giant Disc Bridge Saw Machine

Marble Giant Disc Bridge Saw Machine

Limestone Giant Disc Bridge Saw Machine

Slate Giant Disc Bridge Saw Machine

Artificial Stone Giant Disc Bridge Saw Machine

Basalt Giant Disc Bridge Saw Machine

Quartzite Giant Disc Bridge Saw Machine

Sandstone Giant Disc Bridge Saw Machine

Travertine Giant Disc Bridge Saw Machine

Dafon Machines

6YR

6YR

Danny Pan

Danny Pan