Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

20 Heads Horizontal Edger Polishing Machine For Marble Granie

FOB Price:$20000-22000

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Usage:

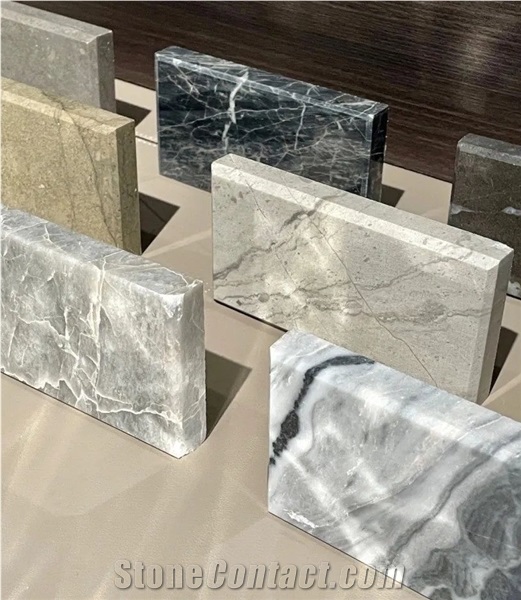

Granite, Marble, Limestone, Quartzite

After-Sale

Lead Time:

15~30 days

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

Trade Terms

Port:

Xiamen Port- China

Delivery Details: FOB,CFR,CIF,EXW

Payment :

More

Machinery Function Features

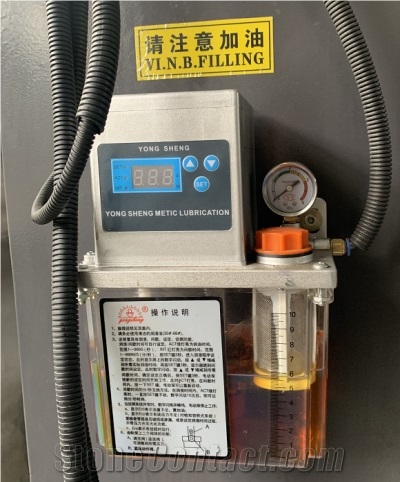

The machine configuration can grind all kinds of slate, stone, microcrystalline stone, and other materials according to the thickness, but the bottom is polished, the flat edge chamfering with side throwing, the upper and lower chamfering with side throwing, the R round belt with side throwing, the upper and lower R belts Round belt side polishing, large bevel, horse belly, slate, stone, microcrystalline and other materials with fixed thickness belt polishing on the back. The rough grinding, fine grinding, and polishing processes are completed at one time, and the brightness after processing is higher than the brightness of the board surface. After the polishing grinding wheel is worn and consumed, the grinding wheel can be automatically compensated during operation without manual adjustment. The structure is advanced and reasonable, with high precision and high efficiency. The operation is convenient and the maintenance is simple. During the grinding process, the feeding speed and the amount of progress can be adjusted, and the maximum processing is 5m/min. The normal use of the machine is equivalent to the workload of 15 people in normal stone processing, and the process defects caused by workers during processing are eliminated. (No. 1, No. 2, leveling, No. 3 motor upside down, can be adjusted upward 45-70 degrees, No. 4 motor down, can be adjusted down 45-70 degrees, 5.6.7, 8, 9, 10 grinding head processing Flat side, can be adjusted upwards 45-70 degrees simultaneously, 11.12.13, No. 14 motors are upside down, and can also swing up and down to process R circles, 5.16.17, No. 18 motors are down, and can also swing up and down to process R circles)

Technical Data

Parameters |

Unit |

DFWP-20 |

Machine overall length |

mm |

6000 |

Grinding tool diameter |

mm |

120 |

Machine overall width |

mm |

1600 |

Belt advancement speed |

mm/min |

1-4 |

Standard diameter of chamfering wheels |

mm |

120 |

Bevelling /Chamfering spindle power |

kw |

3.5 |

Max. diameter of calibrating wheel |

mm |

120 |

Max. processing thickness |

mm |

80 |

Grinding spindle power |

kw |

3.5 |

Sound pressure level |

dB |

60 |

Machine overall height |

mm |

2000 |

Worktop height |

mm |

800 |

Main motor power |

kw |

3.5 |

Calibrating/shaping/cutting spindle power |

kw |

7.5 |

Standard diameter of polishing wheels |

mm |

120 |

Total power |

kw |

50 |

Min. processing thickness |

mm |

10 |

Min. processing width |

mm |

60 |

Approx. Weight |

Kg |

6000 |

Max. diameter of shaping wheel |

mm |

120 |

Video

Install Video

Operation Video

Screen.PrimaryScreen.Bounds.Height

Recommended Edge Profiling, Polishing Machine Products

Related Products:

6YR

6YR

Danny Pan

Danny Pan