Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesStone Carving,Engraving Machine

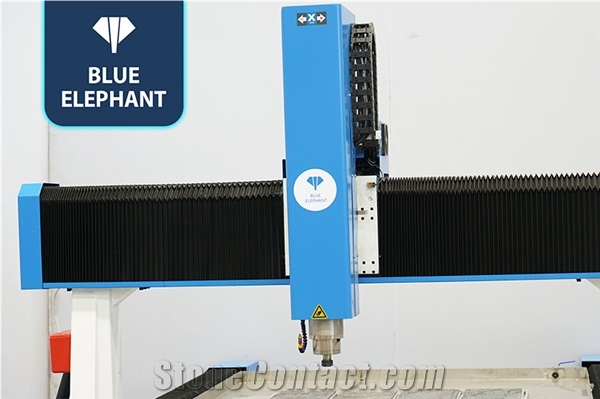

Marble Granite Quartz Engraving Machine With Horizontal Saw Spindle

FOB Price:$7000-9000

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesStone Carving,Engraving Machine

Usage:

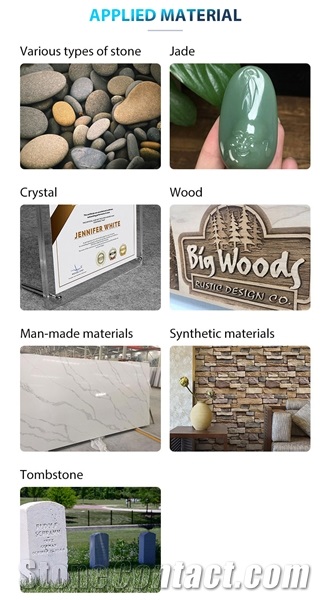

Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Lead Time:

90days

Warranty:12 Months

Install and Guarantee:Remote guidance installation

Maintenance:Online software upgrade, Remote troubleshooting

Trade Terms

Port:

Qingdao- China

Delivery Details: FOB,CIF,EXW,DDU

Payment :

Machinery Function Features

This customized stone CNC router is able to cut, engrave, and shape stone slabs to create intricate designs. It is typically equipped with the DSP A11 control system that manages the movement and speed of the machine. Moreover, the extra added a powerful saw spindle can horizontally cut stone slabs at high speed.

1. DSP A11 control system has a built-in watchdog timer that monitors the system and prevents it from crashing or malfunctioning. It also has a fault self-diagnosis function that can detect and diagnose any problems with the system, making it easier to troubleshoot and fix issues.

2. The high 400mm Z axis allowes 600mm materials feeding height, which made loading be more convenient. 3. Fuling inverter uses advanced control algorithms to maintain a constant speed and torque, even when the load changes. This allows for consistent cutting performance and reduces wear and tear on the machine.

1. DSP A11 control system has a built-in watchdog timer that monitors the system and prevents it from crashing or malfunctioning. It also has a fault self-diagnosis function that can detect and diagnose any problems with the system, making it easier to troubleshoot and fix issues.

2. The high 400mm Z axis allowes 600mm materials feeding height, which made loading be more convenient. 3. Fuling inverter uses advanced control algorithms to maintain a constant speed and torque, even when the load changes. This allows for consistent cutting performance and reduces wear and tear on the machine.

Technical Data

Parameters |

Unit |

E-1228 |

Head motor power |

7 |

5.5 |

Max. workable thickness |

4 |

400 |

Recommended Stone Carving,Engraving Machine Products

Related Products:

Machinery

Stone Factory Machines

Stone Finishing Profiling Machines

Stone Carving Engraving Machine

Granite Carving Engraving Machine

Marble Carving Engraving Machine

Limestone Carving Engraving Machine

Slate Carving Engraving Machine

Onyx Carving Engraving Machine

Artificial Stone Carving Engraving Machine

Basalt Carving Engraving Machine

Quartzite Carving Engraving Machine

Sandstone Carving Engraving Machine

Travertine Carving Engraving Machine

Blue Elephant Machines

5YR

5YR

Jack Zhang

Jack Zhang