Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

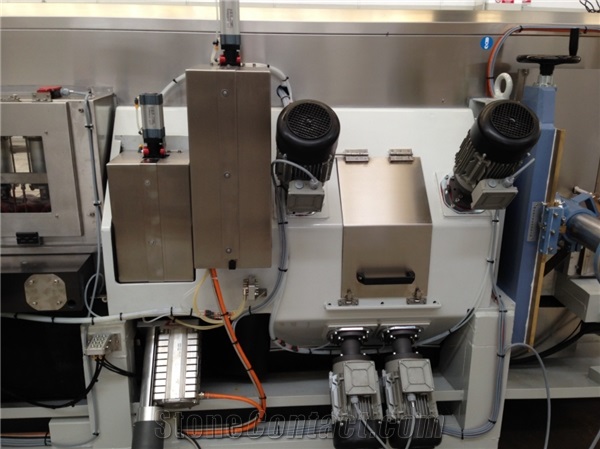

EDILPLUS - Conveyor Belt Edge Polisher

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Usage:

Granite, Marble, Limestone, Quartzite

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Remote troubleshooting, Field troubleshooting

Machinery Function Features

EDILPLUS: the detail that makes the difference

Automatic mutli-spindle belt edge polishing machines, manufactured according to the up-to-date concepts and structural principles, they are remarkable for their performance and production on every kind of material. On materials used in the building field, furnishings and monuments they are able to carry out at the same time: gauging/calibration, straight edge polishing, bevels, lower and upper grooves.

THE EXCLUSIVE FEATURES OF A COMANDULLI MACHINE: EDILPLUS

Steel structure, electrowelded, fully worked by milling machines.

Main covers in stainless steel.

All our machines are protected against corrosion through a modern treatment that follows different phases: sandblasting, metallization and painting. The painted covers are subject to cataphoresis treatment, cartes in stainless steel.

Possibility of polishing the edge without the contrast bar, due to the special sliding system of the conveyor belt and the slab locking – by pneumatic pistons.

Each spindle is independent.

Possibility of polishing straight edges on slab of different thickness and size, one after the other.

Water collecting tank equipped with two lateral outlets.

Colour touch screen.

Conveyor belt width 600mm; operated by a manual variable-speed drive, automatic speed adjustment from control panel; Belt driven on stainless steel plate.

NEW DYNAMIC/SMART BELT SPEED FUNCTION: machine equipped with special software that, during the automatic cycle, varies automatically the belt speed to reduce donwtimes according to the kind working and the tools to be utilised.

Laser to detect the position of the pieces on the belt and their length.

EQUIPMENTS

Calibrating spindle assembled on two orthogonal axes: the vertical one with motorised positioning and keyboard, the horizontal one with manual positioning. Possibility to tilt to 90°.

Floating spindles for the edge (n. 8).

Spindles for the bevels (n. 4)

Spindle for upper groove tilting to 45°

Extendible bar to support bigger pieces.

Rollers for material loading/unloading.Possibility to polish narrow pieces 5 cm width.

OPTIONS

Possibility to make partial workings with the calibrator or the drip unit (vertcal axis motorised and visualised on the screen).

N. 2 additional polishing spindles (10 in total)

n. 2 addional bevelling spindles (6 in total)

Vertical spindle for smoothing the calibrated strip or bushammering the slab surface.

Opposite upper groove spindle (double upper groove) to make parallel cuts.

Centralized automatic lubrication system.

Possibility to polish slabs with minimum thickness 0,5 cm.

TMM group: lock device to realise perfect bevels

Automatic mutli-spindle belt edge polishing machines, manufactured according to the up-to-date concepts and structural principles, they are remarkable for their performance and production on every kind of material. On materials used in the building field, furnishings and monuments they are able to carry out at the same time: gauging/calibration, straight edge polishing, bevels, lower and upper grooves.

THE EXCLUSIVE FEATURES OF A COMANDULLI MACHINE: EDILPLUS

Steel structure, electrowelded, fully worked by milling machines.

Main covers in stainless steel.

All our machines are protected against corrosion through a modern treatment that follows different phases: sandblasting, metallization and painting. The painted covers are subject to cataphoresis treatment, cartes in stainless steel.

Possibility of polishing the edge without the contrast bar, due to the special sliding system of the conveyor belt and the slab locking – by pneumatic pistons.

Each spindle is independent.

Possibility of polishing straight edges on slab of different thickness and size, one after the other.

Water collecting tank equipped with two lateral outlets.

Colour touch screen.

Conveyor belt width 600mm; operated by a manual variable-speed drive, automatic speed adjustment from control panel; Belt driven on stainless steel plate.

NEW DYNAMIC/SMART BELT SPEED FUNCTION: machine equipped with special software that, during the automatic cycle, varies automatically the belt speed to reduce donwtimes according to the kind working and the tools to be utilised.

Laser to detect the position of the pieces on the belt and their length.

EQUIPMENTS

Calibrating spindle assembled on two orthogonal axes: the vertical one with motorised positioning and keyboard, the horizontal one with manual positioning. Possibility to tilt to 90°.

Floating spindles for the edge (n. 8).

Spindles for the bevels (n. 4)

Spindle for upper groove tilting to 45°

Extendible bar to support bigger pieces.

Rollers for material loading/unloading.Possibility to polish narrow pieces 5 cm width.

OPTIONS

Possibility to make partial workings with the calibrator or the drip unit (vertcal axis motorised and visualised on the screen).

N. 2 additional polishing spindles (10 in total)

n. 2 addional bevelling spindles (6 in total)

Vertical spindle for smoothing the calibrated strip or bushammering the slab surface.

Opposite upper groove spindle (double upper groove) to make parallel cuts.

Centralized automatic lubrication system.

Possibility to polish slabs with minimum thickness 0,5 cm.

TMM group: lock device to realise perfect bevels

Technical Data

Parameters |

Unit |

EDILPLUS 8+4 |

EDILPLUS 8+6 |

Conveyor Belt width |

mm |

600 |

600 |

Min. processing thickness |

mm |

10 |

10 |

Standard diameter of chamfering wheels |

mm |

260 |

260 |

Approx. Weight |

Kg |

4000 |

4500 |

Machine overall width |

mm |

1800 |

1800 |

Machine overall height |

mm |

1700 |

1700 |

Worktop height |

mm |

780 |

780 |

Total power |

kw |

28 |

32 |

Standard diameter of polishing wheels |

mm |

130 - 150 |

130 - 150 |

Max. diameter of calibrating wheel |

mm |

260 |

260 |

Belt advancement speed |

mm/min |

0 ÷ 3 |

0 ÷ 3 |

Number of Bevelling/chamfering spindles |

nr |

4 |

4 |

Max. processing thickness |

mm |

80 |

80 |

Machine overall length |

mm |

5500 |

6000 |

Number of dressing/polishing spindles |

nr |

8 |

8 |

Min. processing width |

mm |

60 |

60 |

Mara Comandulli

Mara Comandulli