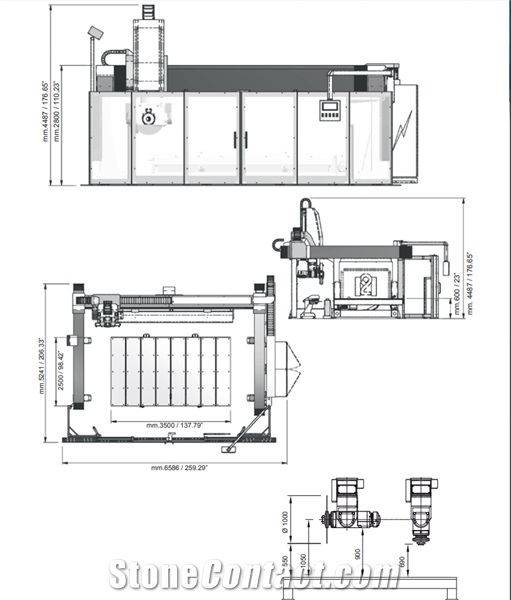

Zenith 1000 5 Interpolated Axis CNC Bridge Cutting Machine

FOB Price:

Automatic multifunction machine with 5 interpolated axis. The structure of the vertical carriage in the form of a cage, is performed in electro-welded steel which ensures the machine more stability and rigidity, minimizing the vibrations generated during processings.

The high speed movements of the X, Y and Z axis, are obtained with brushless motors and the movement is performed by automatically lubricated recirculating roller balls slide guides.

The movement of the vertical Z axis is performed by a screw with recirculating balls supported by a pneumatic piston compensator. The translational motion of the beam is performed by a motor positioned between two pinions which scroll on a precision rack with inclined teeth.

Parameters |

Unit |

Zenith 1000 |

Dimensions of the work table(L×W) |

mm |

3500 x 2500 |

Machine height |

mm |

4487 |

Head motor power |

kw |

31 |

Max number of interpolated axes |

nr |

5 |

Max. revolutions of the spindle unit |

r/min |

7500 |

Tool connection |

ISO 50 |

|

Horizontal stroke(X axis travel) |

mm |

3650 |

C axis blade rotation |

° |

0 ÷ 370 |

Store tools change |

nr |

17 + aggregate |

Machine width |

mm |

5241 |

Disc diameter |

mm |

max. 1000/70 blade hole |

Machine length |

mm |

6586 |

Bridge transversal stroke(Y axis travel) |

mm |

3300 |

Vertical stroke speed (Z displacement speed) |

m/min |

7.5 |

Approximate weight without table |

Kg |

8200 |

Max. cutting depth |

mm |

350 |

Head raising/lowering stroke(Z axis travel) |

mm |

1000 |

Tools holder head inclination(A axis blade rotation) |

° |

-140 / +140 |

Standard voltage |

Volt / Hz |

400 / 50 |

Horizontal stroke speed(X axis displacement speed) |

m/min |

30 |

Transversal stroke speed (Y displacement speed) |

m/min |

30 |

System based on an embedded windows base with an integrated control board CNI machine supported by a of touch screen monitor and remote control display system ensuring the easy execution of management operations in a simple and intuitive way.

The electronic components of the machine are controlled by products with recognized worldwide brands that ensure easy availability in the case of failure.

Cad Cam software manages and optimizes all the phases of the process: from the design and/or import of parts, the definition of machining strategies, to the estimated timing and control of collisions with 3D simulation, through to the provision of parts and underparts on the workbench

- Automatic generation of roughing cycles, coring, drilling, finishing, profiling, pocketing and polishing.

- Free drawing of geometric entities arches, bi-arcs,lines, rectangles, squares, ellipses, circles, regular polygons, joints, chamfers, construction designs.

- Drawing from predefined parametric models: vanitytops, kitchen tops, tables, including managing the downside, the canals and the sink, etc.

- Definition of guided basic three-dimensional surfaces, starting with sections and/or guidelines drawn on the XY plane (frames, shower trays, concave convex sinks, sinks in multiple sections).

- Write in different fonts also shaped profiles, including characters in italics, characters with drills, working downside, relief and engraving with sharp edges, fenerary art.

- Nesting manual, facilitates and optimize arrangement of the pieces on the worktable.

Related Products:

Michela Della Rosa

Michela Della Rosa