Home ProductsStone MachineryArtificial Stone MachinesArtificial Stone Polishing, Calibration Machine

Wet Polishing Machine for Artificial Stone, Porcelain tile surface finishing

FOB Price:

Type:

Artificial Stone MachinesArtificial Stone Polishing, Calibration Machine

Usage:

Artificial Stone

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Remote troubleshooting, Field troubleshooting

You may also like

Machinery Function Features

Sizes from 300mm to 1650mm

From 8 to 24 heads

Machine for tile surface finishing.

The polisher with a swinging motion operated by two beams is used to control the transversal movement and speed of the heads in infeed and outfeed in an independent way in order to meet any kind of manufacturing requirement.

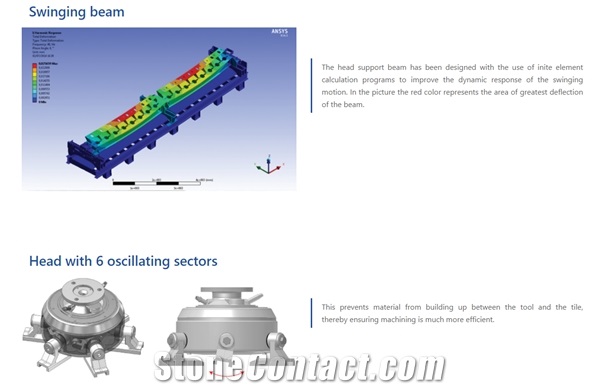

The head support beam has been designed with the use of inite element calculation programs to improve the dynamic response of the swinging motion. In the picture the red color represents the area of greatest deflection of the beam.

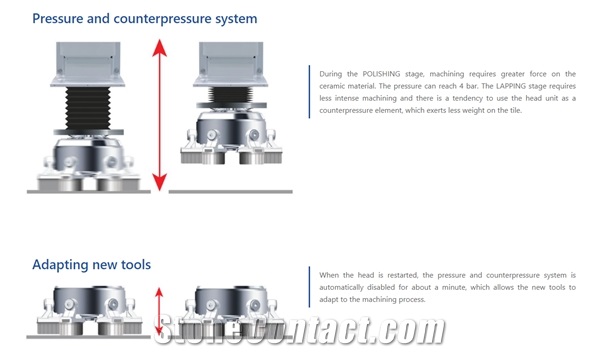

This prevents material from building up between the tool and the tile, thereby ensuring machining is much more efficient.

During the POLISHING stage, machining requires greater force on the ceramic material. The pressure can reach 4 bar. The LAPPING stage requires less intense machining and there is a tendency to use the head unit as a counterpressure element, which exerts less weight on the tile.

When the head is restarted, the pressure and counterpressure system is automatically disabled for about a minute, which allows the new tools to adapt to the machining process.

On each head is mounted a position gauge to continuously control the wear of the tools.

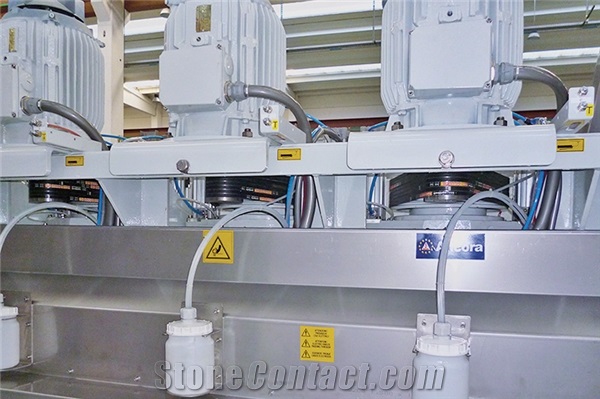

Lubrication system can be used to periodically top up with clean lubricant. Excess grease is ejected into the designated containers. Correct maintenance on the system ensures there is no water infiltration and condensation in the heads.

Tile absence and/or breakage control, commanding a sequenced automatic lifting of the heads.

New variable Geometry Polishing Head

To achieve:

Better gloss homogeneity

Less tools consumption

Greater polishing flexibility

From 8 to 24 heads

Machine for tile surface finishing.

The polisher with a swinging motion operated by two beams is used to control the transversal movement and speed of the heads in infeed and outfeed in an independent way in order to meet any kind of manufacturing requirement.

The head support beam has been designed with the use of inite element calculation programs to improve the dynamic response of the swinging motion. In the picture the red color represents the area of greatest deflection of the beam.

This prevents material from building up between the tool and the tile, thereby ensuring machining is much more efficient.

During the POLISHING stage, machining requires greater force on the ceramic material. The pressure can reach 4 bar. The LAPPING stage requires less intense machining and there is a tendency to use the head unit as a counterpressure element, which exerts less weight on the tile.

When the head is restarted, the pressure and counterpressure system is automatically disabled for about a minute, which allows the new tools to adapt to the machining process.

On each head is mounted a position gauge to continuously control the wear of the tools.

Lubrication system can be used to periodically top up with clean lubricant. Excess grease is ejected into the designated containers. Correct maintenance on the system ensures there is no water infiltration and condensation in the heads.

Tile absence and/or breakage control, commanding a sequenced automatic lifting of the heads.

New variable Geometry Polishing Head

To achieve:

Better gloss homogeneity

Less tools consumption

Greater polishing flexibility

Recommended Artificial Stone Polishing, Calibration Machine Products

Stefano Baraldi

Stefano Baraldi