Home ProductsStone MachineryStone Factory MachinesStone Tile Cutting MachinesHydraulic Stone Splitting Machine

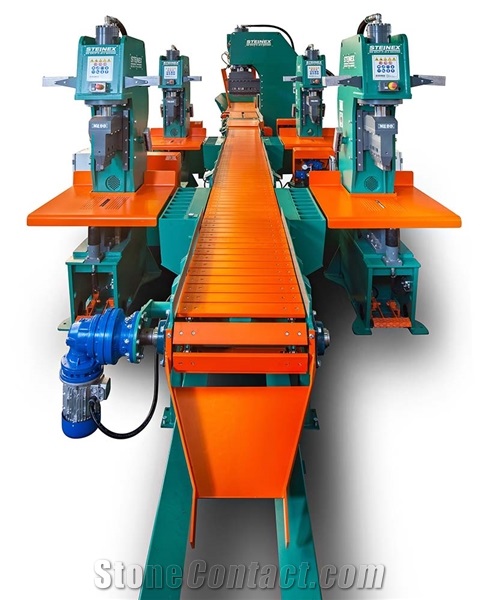

IGLOO cubes stone splitting machine

FOB Price:

Type:

Stone Factory MachinesStone Tile Cutting MachinesHydraulic Stone Splitting Machine

Usage:

Granite, Marble, Limestone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Remote guidance installation

Maintenance:Regular guidance & maintenance

You may also like

Machinery Function Features

The Igloo stone splitter is an open frame machine model, highly productive, simple to maintain, an ideal solution for your quarries and the best choice as cubes splitting machine. Splitting machine models range from 160-640mm in blade length and 20 -180 tons of splitting pressure. All models are supplied with a highly efficient hydraulic unit using only the best performing hydraulic components. The Igloo machines are designed for splitting hard material in continuous use and are well known throughout the world for their resilience and precision processing hard stone. These machines are used to split granite, limestone, sandstone, slate, porphyry and many other types of natural stone products.

The Igloo 160, 240 and 320 models are used for the production of split paving, cubes and natural stone tiles. The Igloo 400, 480 and 640 for wall stones and large cubes, whilst the Igloo 500 and 600 for split kerbstone, large wall stones and as primary machines in a configured splitting line for the production of various split natural stone products.

High production, low cost stone cobble splitting machine. Our Igloo stone splitters come with various options including conveyors, feeders, hoppers and manipulators to both improve productivity and optimize safety. All Igloo splitters can be configured in Steinex production lines as primary or secondary splitters depending on the model and desired final product.

The Igloo 160, 240 and 320 models are used for the production of split paving, cubes and natural stone tiles. The Igloo 400, 480 and 640 for wall stones and large cubes, whilst the Igloo 500 and 600 for split kerbstone, large wall stones and as primary machines in a configured splitting line for the production of various split natural stone products.

High production, low cost stone cobble splitting machine. Our Igloo stone splitters come with various options including conveyors, feeders, hoppers and manipulators to both improve productivity and optimize safety. All Igloo splitters can be configured in Steinex production lines as primary or secondary splitters depending on the model and desired final product.

Technical Data

Parameters |

Unit |

Igloo 160 |

Igloo 240 |

Igloo 320 |

Igloo 400 |

Igloo 480 |

Igloo 500 |

Igloo 600 |

Igloo 640 |

Blade length |

mm |

160 |

240 |

320 |

400 |

480 |

500 |

600 |

640 |

Splitting force |

t |

20 |

40/60 |

40/60 |

70 |

100/120 |

160 |

160/180 |

100/120 |

Blade adaptation |

RB |

0 |

2 |

1 |

2 |

2 |

3 |

3 |

2 |

Max. working height |

mm |

180 |

320 |

320 |

350 |

450 |

550 |

550 |

450 |

Processed Stone Photos

Recommended Hydraulic Stone Splitting Machine Products

Related Products:

Machinery

Factory Machines

Stone Tile Cutting Machines

Hydraulic Stone Splitting Machine

Granite Hydraulic Stone Splitting Machine

Marble Hydraulic Stone Splitting Machine

Limestone Hydraulic Stone Splitting Machine

Basalt Hydraulic Stone Splitting Machine

Quartzite Hydraulic Stone Splitting Machine

Sandstone Hydraulic Stone Splitting Machine

Travertine Hydraulic Stone Splitting Machine

Steinex Machines

Giovanni Sergio Scalia

Giovanni Sergio Scalia