Home ProductsStone MachineryStone Factory MachinesStone Tile Cutting MachinesMulti-Blade Cross-Cutter,Trimming

Multibreton DXL Automatic Cross-cut Saw for Marble and Grani

FOB Price:

Type:

Stone Factory MachinesStone Tile Cutting MachinesMulti-Blade Cross-Cutter,Trimming

Usage:

Granite, Marble, Quartzite

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

Trade Terms

Delivery Details: FOB

Payment :

Supplier

Breton S.p.A.

Italy

Italy

Eatablished :Dec 31,1962

Main Product:

Stone Machines, Cutting Machine, Polising Machine, Wire Saw, Cnc Machines|

Contact supplier

Machinery Function Features

MULTIBRETON DXL is an automatic cross-cut saw for marble or granite strips, equipped with up to twelve cutting spindles. For each cutting cycle, the machine can saw a single strip or two strips simultaneously - even of different length - into items of the desired size.

THE CUTTING CYCLE

The cutting cycle is fully automated for virtually unattended operating:

1. the marble or granite strip to be cut moves forward while resting on the feeding belt which slides on the milled bench of the machine, and halts close to the pneumatic stop (if existing).

2. a movable aligner to bring the strip into square before starting the cut, is housed on the front part of the machine, opposite the spindle-holding beam.

3. the cut is performed while the spindleholding beam moves orthogonally with respect to the conveyor belt.

Once the cut is carried out, the saw blades lift before getting back to their starting position, and the strip - cut into tiles - is transferred outside the machine, while a new strip to be cut enters the machine.

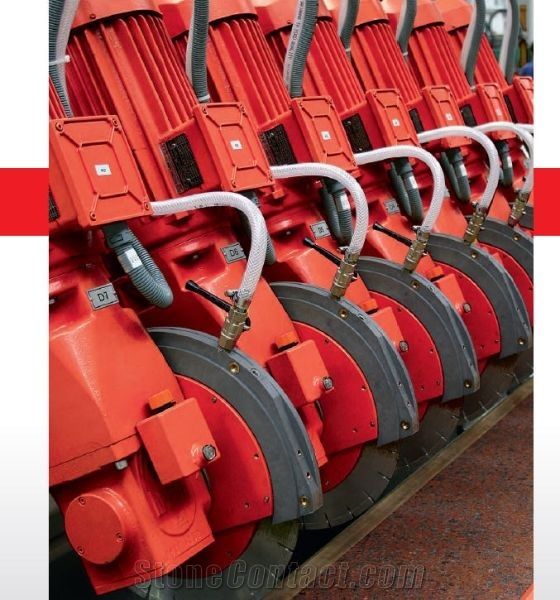

THE CUTTING SPINDLES

The cast-iron spindles slide along the bridge on guides in an oil bath, perfectly protected from water. The spindle positioning is automated, motorized by a screw with lead nuts connected to an electromagnetic clutch and adjusted sequentially for each single spindle.

Once each spindle has reached the programmed position, it is blocked by a hydraulic mechanism. A pneumatic device can exclude each spindle vertically. On request, the machine can be supplied in a special version with simultaneous positioning of all the spindles instead of sequential adjustment of each individual spindle.

THE CUTTING CYCLE

The cutting cycle is fully automated for virtually unattended operating:

1. the marble or granite strip to be cut moves forward while resting on the feeding belt which slides on the milled bench of the machine, and halts close to the pneumatic stop (if existing).

2. a movable aligner to bring the strip into square before starting the cut, is housed on the front part of the machine, opposite the spindle-holding beam.

3. the cut is performed while the spindleholding beam moves orthogonally with respect to the conveyor belt.

Once the cut is carried out, the saw blades lift before getting back to their starting position, and the strip - cut into tiles - is transferred outside the machine, while a new strip to be cut enters the machine.

THE CUTTING SPINDLES

The cast-iron spindles slide along the bridge on guides in an oil bath, perfectly protected from water. The spindle positioning is automated, motorized by a screw with lead nuts connected to an electromagnetic clutch and adjusted sequentially for each single spindle.

Once each spindle has reached the programmed position, it is blocked by a hydraulic mechanism. A pneumatic device can exclude each spindle vertically. On request, the machine can be supplied in a special version with simultaneous positioning of all the spindles instead of sequential adjustment of each individual spindle.

Technical Data

Parameters |

Unit |

Multibreton DXL |

Approximate weight |

kg |

9500 |

Conveyor system control motor power |

kW |

4 |

Machine height (H) |

mm |

2300 |

Machine length (L) |

mm |

2700 |

Max. strip length |

mm |

3500 |

Disc-holder head motor power |

kW |

7.5 |

Min. distance between two contiguous disc |

mm |

200 |

Machine width (W) |

mm |

6500 |

Max. working strip thickness |

mm |

70 marble/40 granite |

Discs diameter |

mm |

360 |

Max.Strip Machinable width |

mm |

650 |

Main conveyor belt speed |

m/min |

2/35(min/max) |

Min.Strip Machinable width |

mm |

200 |

Number of disc-holder heads |

nr |

5 min-12 max |

Water requirement for each spindle |

l/min |

150 |

Average level of equivalent sound pressure |

dbA |

84 |

Recommended Multi-Blade Cross-Cutter,Trimming Products

Stefano Titotto

Stefano Titotto