Home ProductsStone MachineryStone Factory MachinesStone Block Cutting MachinesSingle Wire Block Squaring Machine

MEM 2000 - MEM ECO Single Wire Cutting,Block Squaring Machine

FOB Price:

Type:

Stone Factory MachinesStone Block Cutting MachinesSingle Wire Block Squaring Machine

Usage:

Granite, Marble, Limestone, Onyx, Basalt, Quartzite, Sandstone

After-Sale

Warranty:3 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Regular guidance & maintenance

Machinery Function Features

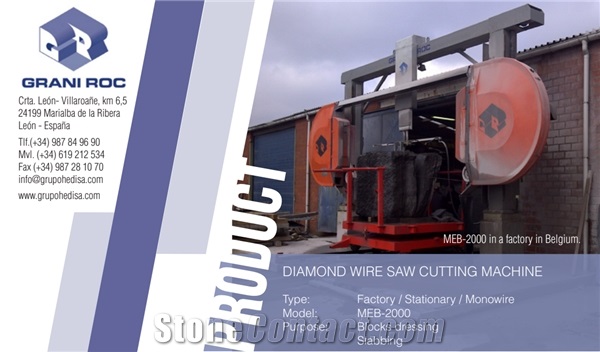

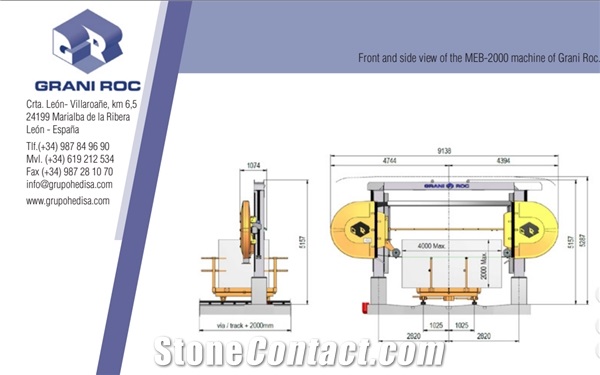

The MEB 2000 wire saw from Grani Roc is a machine designed for dressing and slabbing stone blocks. The machine is built with the classic setup of static structure and rotating trolley to position and to move the block.

· The bridge structure and pillars of the machine are built in laminated steel. All surfaces of contact between the different parts are machined for guaranteeing high precision in assembly and also in the cutting process.

· All the steel elements of the structure are subjected to a surface finishing consisting of a deep cleaning and degreasing treatment, a metallization treatment and corresponding protective layers and painting. These treatments enhance the durability of the machine against aggressive weather and working conditions.

· The main motor is direct in the main pulley, and it is controlled by an electronic frequency variator –inverter-, that permits to apply progressive linear speed to the wire and its adjustment to optimize the behaviour and performance of the tool.

· The tensioning of the wire is made pneumatic and automatically with indication of wire breakage or shortage. In this way the machine controls automatically the down movement of the machine, adapting it to the optimum working tension of the wire, avoiding possible breakages

and optimizing its behaviour.

· All the main pulleys –drive and tensioning– and guiding wheels are protected by rubber liners in order to get the necessary traction of the wire. Such liners can be easily changed once they are worn out.

· The machine is equipped with an automatic cooling system for the diamond wire with detection of constant water pressure. This system stops the machine in the case of lack or insufficient water flow, protecting the tool and preventing possible deterioration or damage of the equipment.

· All the up and down screws are protected with hoods against dust and water .

· The machines has an automatic greasing system that injects lubricating liquid in the critical parts of the machine ensuring their correct functioning and the long life of the spare parts.

· The control panel is situated in the lateral part of the machine and moves with it. It has all the drive and protection components and devices of all control and safety equipment of the machine. All these components are standard, allowing easy and quick maintenance and / or replacement.

·The machine has its own mobile compressor, necessary for the pneumatic system for tensioning the wire.

· The trolley is 2.300 x 2.300 mm and has a maximum capacity of 30 Ton. The rotation is manual 360º and can be blocked every 90º.

· The bridge structure and pillars of the machine are built in laminated steel. All surfaces of contact between the different parts are machined for guaranteeing high precision in assembly and also in the cutting process.

· All the steel elements of the structure are subjected to a surface finishing consisting of a deep cleaning and degreasing treatment, a metallization treatment and corresponding protective layers and painting. These treatments enhance the durability of the machine against aggressive weather and working conditions.

· The main motor is direct in the main pulley, and it is controlled by an electronic frequency variator –inverter-, that permits to apply progressive linear speed to the wire and its adjustment to optimize the behaviour and performance of the tool.

· The tensioning of the wire is made pneumatic and automatically with indication of wire breakage or shortage. In this way the machine controls automatically the down movement of the machine, adapting it to the optimum working tension of the wire, avoiding possible breakages

and optimizing its behaviour.

· All the main pulleys –drive and tensioning– and guiding wheels are protected by rubber liners in order to get the necessary traction of the wire. Such liners can be easily changed once they are worn out.

· The machine is equipped with an automatic cooling system for the diamond wire with detection of constant water pressure. This system stops the machine in the case of lack or insufficient water flow, protecting the tool and preventing possible deterioration or damage of the equipment.

· All the up and down screws are protected with hoods against dust and water .

· The machines has an automatic greasing system that injects lubricating liquid in the critical parts of the machine ensuring their correct functioning and the long life of the spare parts.

· The control panel is situated in the lateral part of the machine and moves with it. It has all the drive and protection components and devices of all control and safety equipment of the machine. All these components are standard, allowing easy and quick maintenance and / or replacement.

·The machine has its own mobile compressor, necessary for the pneumatic system for tensioning the wire.

· The trolley is 2.300 x 2.300 mm and has a maximum capacity of 30 Ton. The rotation is manual 360º and can be blocked every 90º.

Technical Data

Parameters |

Unit |

MEM 2000 |

MEM ECO |

Installed/Fast lowering unit power |

kw |

21 |

21 |

Useful width in horizontal cut |

mm |

3500 |

3500 |

Approximative Weight |

Kg |

6000 |

5000 |

Machine height (H) |

mm |

5350 |

5550 |

Machine Width (W) |

mm |

9200 |

8200 |

Length of rail coupling for trolley |

m |

6 |

6 |

Forward speed of the trolley |

mm/min |

0 – 3000 |

0 – 3000 |

Diamond wire linear speed |

m/min |

0 – 40 |

0 – 40 |

Electrical connection |

V |

3 x 380 V + T + N |

3 x 380 V + T + N |

Block max. cutting height |

mm |

2000 |

2000 |

Worktable load capacity |

T |

30 |

30 |

Main motor power |

kw |

15 |

15 |

Dimensions of turning trolley |

mm |

2300x2300 |

2300x2300 |

Min. water pressure required |

bar |

4 |

4 |

Useful width in vertical cut |

mm |

4000 |

4000 |

Diameter of the main wheels |

mm |

2 x 2000 |

4 x 950 |

Block max. cutting width |

mm |

2000 |

2000 |

Machine length (L) |

mm |

2000+Rails |

2000+Rails |

Recommended Single Wire Block Squaring Machine Products

Related Products:

Machinery

Factory Machines

Stone Block Cutting Machines

Single Wire Block Squaring Machine

Granite Single Wire Block Squaring Machine

Marble Single Wire Block Squaring Machine

Limestone Single Wire Block Squaring Machine

Onyx Single Wire Block Squaring Machine

Basalt Single Wire Block Squaring Machine

Quartzite Single Wire Block Squaring Machine

Sandstone Single Wire Block Squaring Machine

Grani Roc Machines

Alailson Vescovi

Alailson Vescovi