Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesSink Hole Cutting Machine

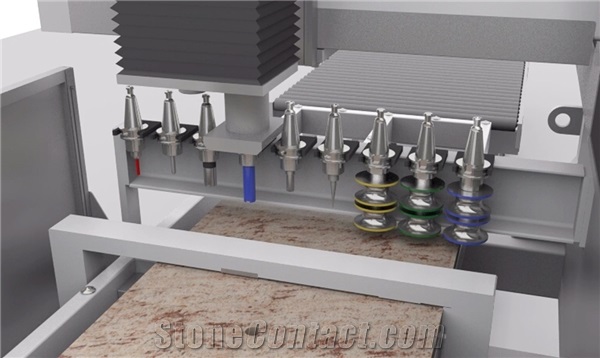

Prussiani TORNADO- 3 axis CNC sink hole, cutting and polishing machine

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesSink Hole Cutting Machine

Usage:

Granite, Marble, Limestone, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting

Machinery Function Features

Prussiani TORNADO, 3 axis CNC sink cutting and polishing machine with auto-tool change.

A revolutionary high production full CNC controlled router designed for optimum cutting and polishing of Kitchen sinks and vanity bowls.

All the functionality and quality of full fledge CNC routers, but without the hefty price tag, and the large floor space of full size machines.

Easy to manage

Quick workpiece positioning thanks to the Quickzero™ reference system

Easy to program and operate one day training and ready to work

Automatic Locking System (ALS) of workpiece in place no suction cups needed

Machine easy to use intuitive CAD/CAM software

Perfect polish due to the always true surface reference created by “ALS”

Hard center-line arrow to quickly locate the cut out location

Easy and lowered maintenance planning controlled and guided by CNC

No risk of oil stains on the marble slabs lubrication with EP1 density grease

A revolutionary high production full CNC controlled router designed for optimum cutting and polishing of Kitchen sinks and vanity bowls.

All the functionality and quality of full fledge CNC routers, but without the hefty price tag, and the large floor space of full size machines.

Easy to manage

Quick workpiece positioning thanks to the Quickzero™ reference system

Easy to program and operate one day training and ready to work

Automatic Locking System (ALS) of workpiece in place no suction cups needed

Machine easy to use intuitive CAD/CAM software

Perfect polish due to the always true surface reference created by “ALS”

Hard center-line arrow to quickly locate the cut out location

Easy and lowered maintenance planning controlled and guided by CNC

No risk of oil stains on the marble slabs lubrication with EP1 density grease

Technical Data

Parameters |

Unit |

TORNADO |

Min. Processing Width |

mm |

400 |

Tool stations number |

nr |

9 |

Machine overall width |

mm |

2.200 |

Machine overall length |

mm |

3.810 |

Tool-holder spindle motor power |

kW |

14 |

Max total absorbed power |

kW |

16 |

Z axis stroke |

mm |

250 |

Spindle tool holder |

ISO 40 |

|

Z axis rapid speed |

m/min |

15 |

Machine overall height |

mm |

2.480 |

Y axis stroke |

mm |

800 |

Min. processing thickness |

mm |

10 |

Approx. Weight |

Kg |

3.100 |

Tool-holder spindle rotation speed |

rpm |

0-10.000 |

X axis stroke |

mm |

1.200 |

Y axis rapid speed |

m/min |

35 |

Max. processing thickness |

mm |

40 |

X axis rapid speed |

m/min |

35 |

Sound pressure level |

dB |

80 ÷ 90 |

Tool-holder spindle motor torque |

Nm |

66 |

Control system |

Quickzero-CAD/CAM |

|

Max. Processing Width |

mm |

1020 |

Sink cutout size |

mm |

950 x 630 |

Work Example

Quick workpiece positioning thanks to the Quickzero™ reference system

Easy to program and operate one day training and ready to work

Automatic Locking System (ALS) of workpiece in place no suction cups needed

Machine easy to use intuitive CAD/CAM software

Recommended Sink Hole Cutting Machine Products

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Sink Hole Cutting Machine

Granite Sink Hole Cutting Machine

Marble Sink Hole Cutting Machine

Limestone Sink Hole Cutting Machine

Onyx Sink Hole Cutting Machine

Artificial Stone Sink Hole Cutting Machine

Basalt Sink Hole Cutting Machine

Quartzite Sink Hole Cutting Machine

Sandstone Sink Hole Cutting Machine

Travertine Sink Hole Cutting Machine

Prussiani Machines

Mario Giorgio Prussiani

Mario Giorgio Prussiani