Home ProductsStone MachineryStone Factory MachinesStone Tile Cutting MachinesMulti-Blade Cross-Cutter,Trimming

M702-M705 - Single and double disc automatic cross cutting machines

FOB Price:

Type:

Stone Factory MachinesStone Tile Cutting MachinesMulti-Blade Cross-Cutter,Trimming

Usage:

Granite, Marble, Limestone, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Remote troubleshooting, Field troubleshooting

Machinery Function Features

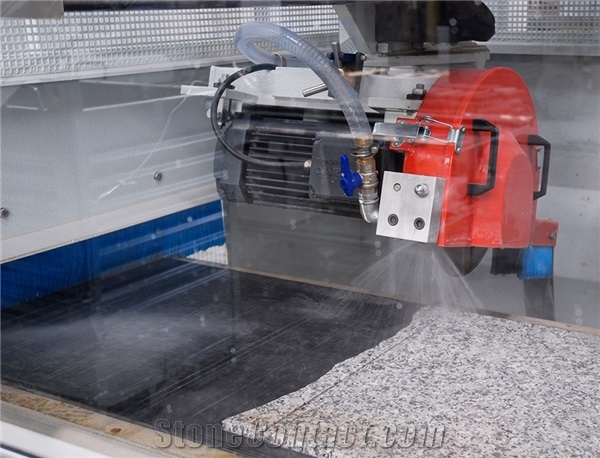

Automatic cycle machines equipped with one or two diamond discs for the elimination of the heads and tails of marble or granite strips or for the production of ends trimmed strips with predetermined modular length. They are used in high production finishing lines.

The cycle, controlled by PLC, is performed first with the cutting of the strip and then, after its removal, with the positioning of the next strip.

Automatic machines for the cross cutting of marble and granite strips by means of diamond discs.

The automatic cross cutting machines M702 and M705 have been designed for the head and tail cut of strips for the continuous cycle processing.

The orthogonal cuts are performed close to the two irregular parts of the strip to allow their subsequent elimination.

M702 and M705 complete automation avoids the need of the manual intervention by the operator.

The PLC controlled program allows to get also intermediate cuts for the production of finished elements by exploiting the whole strip length.

The cycle, controlled by PLC, is performed first with the cutting of the strip and then, after its removal, with the positioning of the next strip.

Automatic machines for the cross cutting of marble and granite strips by means of diamond discs.

The automatic cross cutting machines M702 and M705 have been designed for the head and tail cut of strips for the continuous cycle processing.

The orthogonal cuts are performed close to the two irregular parts of the strip to allow their subsequent elimination.

M702 and M705 complete automation avoids the need of the manual intervention by the operator.

The PLC controlled program allows to get also intermediate cuts for the production of finished elements by exploiting the whole strip length.

Technical Data

Parameters |

Unit |

M702MV Marble |

M702GV Granite |

M705GV Marble/Granite |

Machine length (L) |

mm |

4100 |

4100 |

5400 |

Compressed air requirement |

NL/min |

25 |

25 |

50 |

Discs diameter |

mm |

350 |

350 |

350 |

Cooling Water minimum pressure |

bar |

1,5 |

1,5 |

1,5 |

Max. strip length |

mm |

3500 |

3500 |

3500 |

Installed electrical power |

kw |

7 |

9 |

24,5 |

Number of disc-holder heads |

nr |

1 |

1 |

2 |

Disc-holder head motor power |

kw |

5.5 |

7.5 |

11 |

Infeed roller bench motor power |

kw |

- |

- |

0,75 |

Compressed air minimum pressure |

bar |

6 |

6 |

6 |

Machine width (W) |

mm |

2100 |

2100 |

2240 |

Conveyor system control motor power |

kw |

1,1 |

1,1 |

1,1 |

Max. working strip thickness |

mm |

50 |

50 |

50 |

Machine height (H) |

mm |

1950 |

1950 |

2380 |

Bridge advancement speed |

m/min |

1,5 ÷ 12 |

1,5 ÷ 12 |

1,2 ÷ 10 |

Main conveyor belt speed |

m/min |

3 ÷ 23 |

3 ÷ 23 |

3 ÷ 23 |

Water requirement for each spindle |

L/min |

15 |

15 |

30 |

Approximate weight |

Kg |

3300 |

3300 |

6000 |

Max.Strip Machinable width |

mm |

650 |

650 |

650 |

Recommended Multi-Blade Cross-Cutter,Trimming Products

Related Products:

Machinery

Factory Machines

Stone Tile Cutting Machines

Multi Blade Cross Cutter Trimming

Granite Multi Blade Cross Cutter Trimming

Marble Multi Blade Cross Cutter Trimming

Limestone Multi Blade Cross Cutter Trimming

Quartzite Multi Blade Cross Cutter Trimming

Sandstone Multi Blade Cross Cutter Trimming

Travertine Multi Blade Cross Cutter Trimming

Pedrini Machines

Giambattista Pedrini

Giambattista Pedrini