Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesLeveling Machine

Comandulli Volcano Bench sawing and milling machine

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesLeveling Machine

Usage:

Granite, Marble, Limestone, Artificial Stone, Quartzite

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Remote troubleshooting

Machinery Function Features

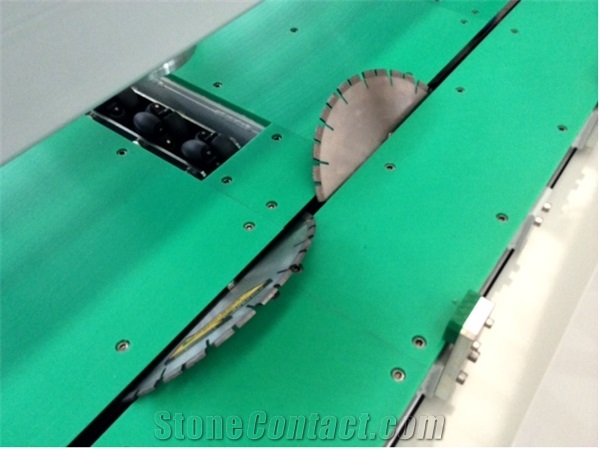

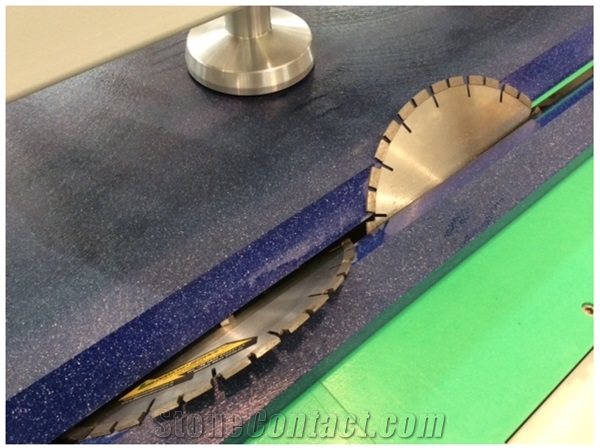

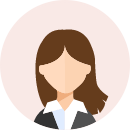

Machine that makes “V” cuts on marble granite and engineered stone slabs by means of diamond discs

Fixed bench machine designed and manufactured according to the up-to date concepts and fitted for making 45° degrees cut to realise V-grooves. The high speed of the holding spindle carriage and its special automatic devices allow it to achieve very high production levels.

Features

THE EXCLUSIVE FEATURES OF A COMANDULLI MACHINE: VOLCANO

Main protection covers in stainless steel.

Strong electrowelded machine main structure fully worked by a milling machine

To prevent the machinery from rust, its structure and main parts are metallized through a modern treatment that follows different phases: sandblasting, metallization with zinc wire, priming coat with zinc phosphate epoxy product and final painting with a high solid polyacrylic enamel. Covers submitted to cataphoresis treatment which follows different phases: degreasing of the piece, spry or dipping pre-treatment, electroplating bath which uses the electric power to plate the paint as to make a uniform skin, after-washing and furnace baking.

Monolithic machine (made in one piece – excluding the rollers) that does not need foundations but can lay on the floor.

Carter in acciaio inox.

EQUIPMENTS:

Machine with a fixed bench equipped with n. 2 spindles equipped with diamond wheels diam. 300 mm at 45° (one opposed to the other) to realise sloping cuts.

Spindles assembled on a travelling holding spindle carriage, with pinion/rack system operated by a grar motor; speed 0÷30 m/1’; Spindle sliding on screw ball guides placed on the lower part of the bench, properly protected against water.

Electrowelded loading bench equipped with n. 7 lines of omnidirectional rollers for loading and unloading the slabs.

Reference bar for the workpiece alignment.

Set of pneumatic holding slab pistons (no. 4).

Electric equipment, controlled by PLC; cutting controls both in automatic or manual.

Roller table to support long pieces while working their heads.

Kit including keys, abrasive wheels etc..

Fixed bench machine designed and manufactured according to the up-to date concepts and fitted for making 45° degrees cut to realise V-grooves. The high speed of the holding spindle carriage and its special automatic devices allow it to achieve very high production levels.

Features

THE EXCLUSIVE FEATURES OF A COMANDULLI MACHINE: VOLCANO

Main protection covers in stainless steel.

Strong electrowelded machine main structure fully worked by a milling machine

To prevent the machinery from rust, its structure and main parts are metallized through a modern treatment that follows different phases: sandblasting, metallization with zinc wire, priming coat with zinc phosphate epoxy product and final painting with a high solid polyacrylic enamel. Covers submitted to cataphoresis treatment which follows different phases: degreasing of the piece, spry or dipping pre-treatment, electroplating bath which uses the electric power to plate the paint as to make a uniform skin, after-washing and furnace baking.

Monolithic machine (made in one piece – excluding the rollers) that does not need foundations but can lay on the floor.

Carter in acciaio inox.

EQUIPMENTS:

Machine with a fixed bench equipped with n. 2 spindles equipped with diamond wheels diam. 300 mm at 45° (one opposed to the other) to realise sloping cuts.

Spindles assembled on a travelling holding spindle carriage, with pinion/rack system operated by a grar motor; speed 0÷30 m/1’; Spindle sliding on screw ball guides placed on the lower part of the bench, properly protected against water.

Electrowelded loading bench equipped with n. 7 lines of omnidirectional rollers for loading and unloading the slabs.

Reference bar for the workpiece alignment.

Set of pneumatic holding slab pistons (no. 4).

Electric equipment, controlled by PLC; cutting controls both in automatic or manual.

Roller table to support long pieces while working their heads.

Kit including keys, abrasive wheels etc..

Technical Data

Parameters |

Unit |

Volcano |

Approx. Weight |

Kg |

2700 |

Distance between the edge and the groove |

mm |

30÷200 |

Maximum groove length |

mm |

3500 |

Min. working thickness |

mm |

30 |

Conveyor belt feed speed |

m/min |

0 ÷ 30 m/1' |

Max. working thickness |

mm |

200 |

Disc diameter |

mm |

300 |

Main motor power |

kw |

4 |

Total power |

kw |

10 |

Mara Comandulli

Mara Comandulli