Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

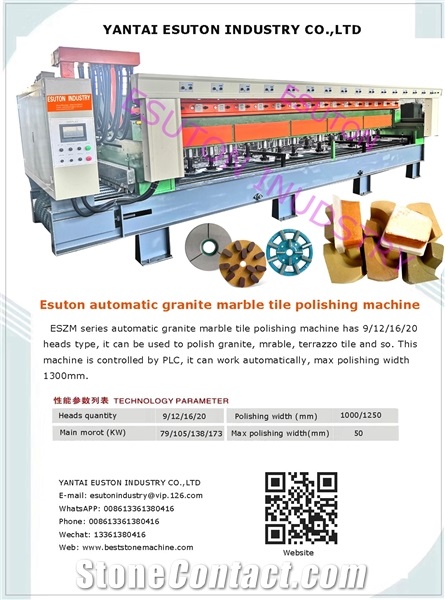

ESUTON AUTOMATIC GRANITE MARBLE TILE POLISHING MACHINE

FOB Price:$25000-50000

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Usage:

Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Lead Time:

1month

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

You may also like

Machinery Function Features

Esuton ESZM Series Automatic Granite Tile Polishing Machine

9/12/16/20 polishing heads type all available.

1. Granite marble tile polishing machine used for polishing granite, marble and terrazzo tiles, the polishing heads adopt elastic device to avoid big shock to the slab when polishing and when polishing head down , this machine is one comprehensive polishing machine with more efficiency and lower abrasive wearing.

2. Using PLC system and display touch screen to achieve intelligent control and work automatically.

3. Easy to operate.the working pressure,the beam travel speed and the belt moving speed can be adjusted according to different stone slab and the finishing glossy.

4. In the front of machine have slab shape detecting device and shape memory to prevent the polishing head out of slab to avoid break the polishing abrasive,having high automation operation and lower labor.

5. Superior material, reasonable structure, completed processing technique, stable performance, high efficiency and energy saving.

6. Using central automatic lubrication system,so that all moving parts and bearings can get a good lubricating effect and longer life.

7. Use Taiwan Linear guide rail for the crossbeam moving to ensure the smooth when moving and keep good precision.

9/12/16/20 polishing heads type all available.

1. Granite marble tile polishing machine used for polishing granite, marble and terrazzo tiles, the polishing heads adopt elastic device to avoid big shock to the slab when polishing and when polishing head down , this machine is one comprehensive polishing machine with more efficiency and lower abrasive wearing.

2. Using PLC system and display touch screen to achieve intelligent control and work automatically.

3. Easy to operate.the working pressure,the beam travel speed and the belt moving speed can be adjusted according to different stone slab and the finishing glossy.

4. In the front of machine have slab shape detecting device and shape memory to prevent the polishing head out of slab to avoid break the polishing abrasive,having high automation operation and lower labor.

5. Superior material, reasonable structure, completed processing technique, stable performance, high efficiency and energy saving.

6. Using central automatic lubrication system,so that all moving parts and bearings can get a good lubricating effect and longer life.

7. Use Taiwan Linear guide rail for the crossbeam moving to ensure the smooth when moving and keep good precision.

Recommended Edge Profiling, Polishing Machine Products

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Edge Profiling Polishing Machine

Granite Edge Profiling Polishing Machine

Marble Edge Profiling Polishing Machine

Limestone Edge Profiling Polishing Machine

Slate Edge Profiling Polishing Machine

Onyx Edge Profiling Polishing Machine

Artificial Stone Edge Profiling Polishing Machine

Basalt Edge Profiling Polishing Machine

Quartzite Edge Profiling Polishing Machine

Sandstone Edge Profiling Polishing Machine

Travertine Edge Profiling Polishing Machine

Esuton Industry Machines

Chris Zhang

Chris Zhang