Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesWaterjet Machines

INTEC 510-G2 High-Pressure Waterjet Systems

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesWaterjet Machines

Usage:

Granite, Marble, Limestone, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting

Machinery Function Features

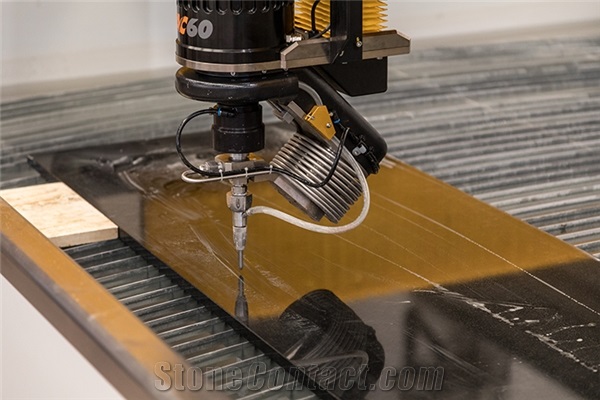

HIGH-PRESSURE WATERJET SYSTEMS

The Intec-G2® can cut almost any material to 8” thick at maximum cutting speed with minimum capital outlay. These machines last longer and require less maintenance, while delivering an easy to use, fast and accurate system at a very competitive price. This series of machines is particularly well-suited for stone industry.

Softec™ Waterjet Cutting Software has been developed by TECHNI Waterjet™ with two very clear goals in mind:

1. To cut parts at minimum cost with the greatest accuracy.

2. To have a simple and intuitive interface with the operator.

The result is a comprehensive “All In One” Windows based software, that is specifically designed for Waterjet Cutting, which maximizes productivity and anyone with PC experience can learn to use quickly and easily.

At the “Heart” of Softec™ is Tru-Cut Technology™, a highly sophisticated algorithms database that determines the optimum cutting speeds and machine ramping characteristics. Once you select the material to be cut, it’s thickness and surface edge finish required, the computer will take care of the rest, ensuring the minimum cutting time for any given part. Programming edges for mitering within seconds. All with one software!

Softec Nest utilizes advance nesting algorithms which have been developed by one of the world’s largest and most awarded CAD and nesting software developers - Geometric Global.

Benefits Include:

Improves profitability by minimising rapid feed times.

Increasing both nesting speed and material yield.

The Intec-G2® can cut almost any material to 8” thick at maximum cutting speed with minimum capital outlay. These machines last longer and require less maintenance, while delivering an easy to use, fast and accurate system at a very competitive price. This series of machines is particularly well-suited for stone industry.

Softec™ Waterjet Cutting Software has been developed by TECHNI Waterjet™ with two very clear goals in mind:

1. To cut parts at minimum cost with the greatest accuracy.

2. To have a simple and intuitive interface with the operator.

The result is a comprehensive “All In One” Windows based software, that is specifically designed for Waterjet Cutting, which maximizes productivity and anyone with PC experience can learn to use quickly and easily.

At the “Heart” of Softec™ is Tru-Cut Technology™, a highly sophisticated algorithms database that determines the optimum cutting speeds and machine ramping characteristics. Once you select the material to be cut, it’s thickness and surface edge finish required, the computer will take care of the rest, ensuring the minimum cutting time for any given part. Programming edges for mitering within seconds. All with one software!

Softec Nest utilizes advance nesting algorithms which have been developed by one of the world’s largest and most awarded CAD and nesting software developers - Geometric Global.

Benefits Include:

Improves profitability by minimising rapid feed times.

Increasing both nesting speed and material yield.

Technical Data

Parameters |

Unit |

INTEC 510-G2 |

Max. air speed |

in/min |

700 |

Bevel cutting area (with PAC 5 axis) |

” |

45,6x107 |

Machine length (L) |

mm |

1650 |

Approximate weight(including table) |

lb |

4431 (with water:15000) |

Machine width (W) |

mm |

920 |

Dimensions of the work table |

in |

61x123 |

Repeatability of motion |

mm |

± 0.025 |

Max. material thickness (with PAC60 cutting head option fitted) |

" |

4,5 |

Cutting area (without PAC 5 axis) |

" |

60x120 |

Cutting area maximized (with PAC 5 axis rotation) |

" |

56,5x118 |

Machine height (H) |

mm |

800 |

Max. material thickness |

" |

8 |

Cutting Accuracy |

mm |

± 0.12 |

Max. cutting speed |

in/min |

700 |

Recommended Waterjet Machines Products

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Waterjet Machines

Granite Waterjet Machines

Marble Waterjet Machines

Limestone Waterjet Machines

Onyx Waterjet Machines

Artificial Stone Waterjet Machines

Basalt Waterjet Machines

Quartzite Waterjet Machines

Sandstone Waterjet Machines

Travertine Waterjet Machines

Gmm Machines

Simone Guazzoni

Simone Guazzoni