Home ProductsStone MachineryStone Factory MachinesStone Surface Processing Machines Slab Polishing Line Machine

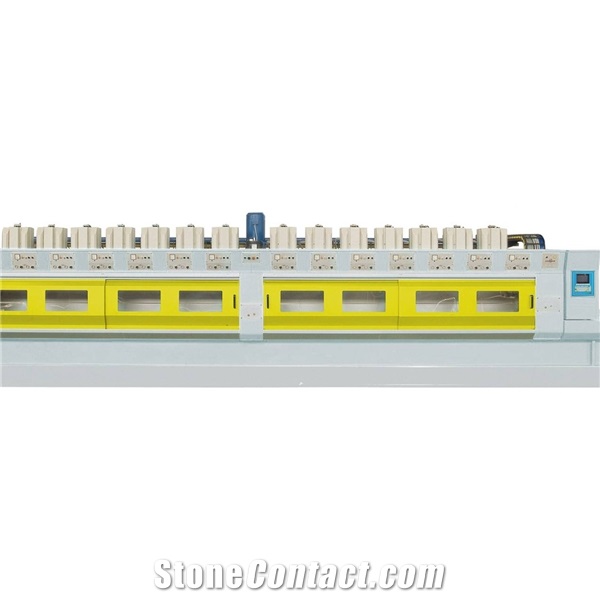

EVEREST 2100 - Granite Slabs Polishing Machine

FOB Price:

Type:

Stone Factory MachinesStone Surface Processing Machines Slab Polishing Line Machine

Usage:

Granite, Basalt, Quartzite

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Regular guidance & maintenance, Remote troubleshooting

Machinery Function Features

FEATURES

- Sturdy electro-welded steel structure base with ground belt sliding surface. 3 mm thick, replaceable STAINLESS steel sheets providing protection against wear and tear. Grease lubrication system to facilitate sliding of the conveyor belt.

- Steel electro-welded spindle-holding beam. Sliding on shoulders equipped with roller cages in oil bath protected by special stainless steel covers. Hardened steel sliding elements both on the shoulders and the beam. Variable speed translation by means of connecting rod and crank regulated by inverter.

POLISHING UNIT

- Spindles made of cast iron with forged steel, chrome-plated and ground shaft sliding on bronze bushes complete with 2 pneumatic lifting cylinders. Each spindle is fitted with a pressure gauge to check the pressure and counter-pressure balancing the heads during the

removal stage.

- 15 kW/20 HP motors with individual or in-sequence start-up. Drive is transmitted by means of pulleys and V-belts.

- 11kW/15 HP motors with individual or in-sequence start-up. Drive is transmitted by means of pulleys and V-belts.

- GOLD series PLANETARY heads Ø 450 mm with 5 GRINDING WHEELS.

- GOLD series TANGENTIAL heads Ø 470 mm with 6 ABRASIVES.

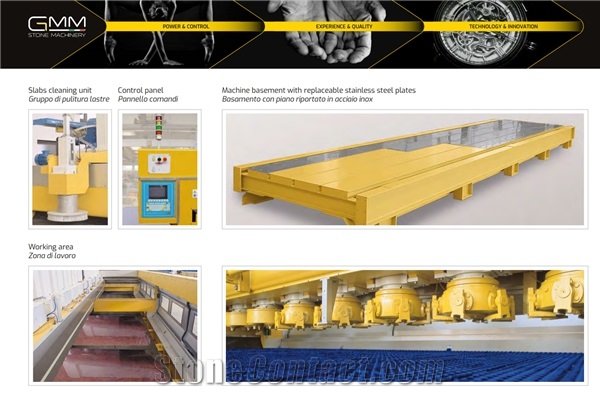

- Cleaning spindle made of cast iron complete with pulleys, belts and 0.75 kW motor coupled to a reduction unit. The upstroke/downstroke is performed by pneumatic cylinder. The spindle is mounted at the end of

the beam, outside of the shoulder.

- Optical detector for scanning the shape of the slabs in sequence and sending the data by serial line to the numerical control.

- Ultrasound sensor positioned at the entrance of the machine that detects the thickness of the material.

- Touch-screen control panel with interactive graphics for a complete control of the machine cycle with automatic starting up in sequence of the belt and beam motor spindles, regulation of spindle upstrokes/downstrokes according to the shape of the slab, control of wear and

tear on abrasives.

- Sturdy electro-welded steel structure base with ground belt sliding surface. 3 mm thick, replaceable STAINLESS steel sheets providing protection against wear and tear. Grease lubrication system to facilitate sliding of the conveyor belt.

- Steel electro-welded spindle-holding beam. Sliding on shoulders equipped with roller cages in oil bath protected by special stainless steel covers. Hardened steel sliding elements both on the shoulders and the beam. Variable speed translation by means of connecting rod and crank regulated by inverter.

POLISHING UNIT

- Spindles made of cast iron with forged steel, chrome-plated and ground shaft sliding on bronze bushes complete with 2 pneumatic lifting cylinders. Each spindle is fitted with a pressure gauge to check the pressure and counter-pressure balancing the heads during the

removal stage.

- 15 kW/20 HP motors with individual or in-sequence start-up. Drive is transmitted by means of pulleys and V-belts.

- 11kW/15 HP motors with individual or in-sequence start-up. Drive is transmitted by means of pulleys and V-belts.

- GOLD series PLANETARY heads Ø 450 mm with 5 GRINDING WHEELS.

- GOLD series TANGENTIAL heads Ø 470 mm with 6 ABRASIVES.

- Cleaning spindle made of cast iron complete with pulleys, belts and 0.75 kW motor coupled to a reduction unit. The upstroke/downstroke is performed by pneumatic cylinder. The spindle is mounted at the end of

the beam, outside of the shoulder.

- Optical detector for scanning the shape of the slabs in sequence and sending the data by serial line to the numerical control.

- Ultrasound sensor positioned at the entrance of the machine that detects the thickness of the material.

- Touch-screen control panel with interactive graphics for a complete control of the machine cycle with automatic starting up in sequence of the belt and beam motor spindles, regulation of spindle upstrokes/downstrokes according to the shape of the slab, control of wear and

tear on abrasives.

Technical Data

Parameters |

Unit |

10 |

12 |

14 |

16 |

18 |

20 |

11+11 (22) |

Belt advancement motor power |

kw |

4/5,5 |

4/5,5 |

4/5,5 |

5,5/7,5 |

5,5/7,5 |

5,5/7,5 |

5,5/7,5 |

Conveyor system forward speed |

m/min |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

2,5 |

Slabs min. processable thickness |

mm |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

Machine overall length |

mm |

9400 |

10700 |

12000 |

13100 |

14200 |

15300 |

16300 |

Planetary head spindle motor power |

kw |

15 |

15 |

15 |

15 |

15 |

15 |

15 |

Total installed electrical power |

kw |

140 |

160 |

180 |

202 |

224 |

246 |

276 |

Bridge travel power |

kw |

5,5 |

2x5,5 |

2x5,5 |

2x7.5 |

2x7.5 |

2x7.5 |

2x7.5 |

Slabs max. processable width |

mm |

2100 |

2100 |

2100 |

2100 |

2100 |

2100 |

2100 |

Machine overall width |

mm |

2700 |

2700 |

2700 |

2700 |

2700 |

2700 |

2700 |

Rough-hewing spindle motor power |

kw |

15 |

15 |

15 |

15 |

15 |

15 |

15 |

Polishing heads/honing units motor power |

kw |

11 |

11 |

11 |

11 |

11 |

11 |

11 |

Number of polishing heads/honing units |

nr |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

Cooling water requirement |

L/min |

200 |

240 |

280 |

320 |

360 |

400 |

440 |

Beam translation motor power |

kw |

2x7.5 |

2x7.5 |

2x7.5 |

2x7.5 |

2x7.5 |

2x7.5 |

2x7.5 |

Beam crosswise movement speed |

m/min |

50 |

50 |

50 |

50 |

50 |

50 |

50 |

Machine overall height |

mm |

2500 |

2500 |

2500 |

2500 |

2500 |

2500 |

2500 |

Slabs max. processable thickness |

mm |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

Cleaning spindle motor power |

kw |

0.75 |

0.75 |

0.75 |

0.75 |

0.75 |

0.75 |

0.75 |

Tangential head spindle motor power |

kw |

11 |

11 |

11 |

11 |

11 |

11 |

11 |

Recommended Slab Polishing Line Machine Products

Simone Guazzoni

Simone Guazzoni