Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

T952 Multifunction 5 Axis CNC Working Center

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

Usage:

Granite, Marble, Limestone, Artificial Stone, Basalt, Quartzite

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Online software upgrade, Remote troubleshooting, Field troubleshooting

Machinery Function Features

This all-in-one 5-axis machine is capable of saw like a sawing centre, to a machine like a machining centre and to polish like a polishing centre.

You will not believe your eyes!

A sawing, machining and polishing power

The electro-spindle has been entirely developed by Thibaut and enables the combination of the performance of:

• A sawing spindle

• A machining spindle

• A polishing spindle

The T952 enables to make the operations of several Machines in one: straight cut, inclined cut, flat polishing, 3D shaping, drilling, edge polishing ….

It is also possible to process thicknesses of 8 inches.

This new THIBAUT spindle coupled with the new THIBAUT 5-axis head enables to combine the performances of 3 machine types while offering more sturdiness and accuracy in the realization of operations enabled by this machine.

Entirely developed by THIBAUT, it offers a very high sturdiness (transmission by cyclo reducer without play). The cross laser enables precise positioning of the vacuum pods on the table.

A very fast return on investment

This all-in-one machine will enable you to make all your sawing, machining and polishing operations. Hence, you will use it intensively and more than if you had 3 separate machines, for a reduced investment. Your return on investment will therefore be quicker.

Its frame and galvanized walls are guaranteed against rust. Its sturdiness guarantees durability, constant accuracy and reliability over several years.

Moreover, its very sturdy technical table is designed to last. Your operators will have to be trained only on one machine for operating and maintenance of this machine. You will therefore be able to save on maintenance costs by having only one machine.

Thibaut machine T952, all-in-one serie. Polishing, sawing, machining

Numerous functions in a reduced space

Buying a workshop or extend a building can be expensive. This « all-in-one » solution allows you to make all the operations of 3 different machines, with only one machine.

Thanks to its versatility, this machine can be adapted to some workshops in which several machines cannot fit.

The linear tool magazine can receive up to 47 tools. It is possible to install several tool magazines.

Design, ergonomics and safety

The T952 is the first machine of the new THIBAUT machine range for which the design has been entirely rethought.

The door structure is self-supporting, without contact with the ground (no foundation required). Those new doors offer a reinforced safety thanks to their dimensions and components.

The door panels are made of transparent polycarbonate with a large glass surface and a big screen directly integrated into the door, easing access to the control panel for the operator while having good visibility of the machining area.

Above the stainless steel control panel, a lighting strip gives signals to the operator during processing (colour code or messages).

To enable the operator to lay documents, an ergonomic tablet is installed under the control panel.

Programming

The machine comes with the very latest user-friendly « Pilot » interface, for more efficiency and speed.

Thanks to the multi-touch screen and control panel built-in to the door, you will be able to command the machine from the end of your fingertips, while having visibility on the working area.

The lighting strip installed above control panel brings information on the progress of the machining.

New functions have been added with this THIBAUT Pilot such as configuration and control of tools according to materials, machining simulation, a library of parametric shapes.

It is possible to prepare the programs on a computer (software T’Cut, eT’cam…) or directly at the machine.

You will not believe your eyes!

A sawing, machining and polishing power

The electro-spindle has been entirely developed by Thibaut and enables the combination of the performance of:

• A sawing spindle

• A machining spindle

• A polishing spindle

The T952 enables to make the operations of several Machines in one: straight cut, inclined cut, flat polishing, 3D shaping, drilling, edge polishing ….

It is also possible to process thicknesses of 8 inches.

This new THIBAUT spindle coupled with the new THIBAUT 5-axis head enables to combine the performances of 3 machine types while offering more sturdiness and accuracy in the realization of operations enabled by this machine.

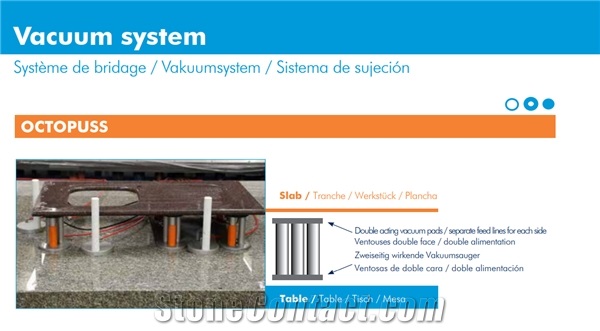

Entirely developed by THIBAUT, it offers a very high sturdiness (transmission by cyclo reducer without play). The cross laser enables precise positioning of the vacuum pods on the table.

A very fast return on investment

This all-in-one machine will enable you to make all your sawing, machining and polishing operations. Hence, you will use it intensively and more than if you had 3 separate machines, for a reduced investment. Your return on investment will therefore be quicker.

Its frame and galvanized walls are guaranteed against rust. Its sturdiness guarantees durability, constant accuracy and reliability over several years.

Moreover, its very sturdy technical table is designed to last. Your operators will have to be trained only on one machine for operating and maintenance of this machine. You will therefore be able to save on maintenance costs by having only one machine.

Thibaut machine T952, all-in-one serie. Polishing, sawing, machining

Numerous functions in a reduced space

Buying a workshop or extend a building can be expensive. This « all-in-one » solution allows you to make all the operations of 3 different machines, with only one machine.

Thanks to its versatility, this machine can be adapted to some workshops in which several machines cannot fit.

The linear tool magazine can receive up to 47 tools. It is possible to install several tool magazines.

Design, ergonomics and safety

The T952 is the first machine of the new THIBAUT machine range for which the design has been entirely rethought.

The door structure is self-supporting, without contact with the ground (no foundation required). Those new doors offer a reinforced safety thanks to their dimensions and components.

The door panels are made of transparent polycarbonate with a large glass surface and a big screen directly integrated into the door, easing access to the control panel for the operator while having good visibility of the machining area.

Above the stainless steel control panel, a lighting strip gives signals to the operator during processing (colour code or messages).

To enable the operator to lay documents, an ergonomic tablet is installed under the control panel.

Programming

The machine comes with the very latest user-friendly « Pilot » interface, for more efficiency and speed.

Thanks to the multi-touch screen and control panel built-in to the door, you will be able to command the machine from the end of your fingertips, while having visibility on the working area.

The lighting strip installed above control panel brings information on the progress of the machining.

New functions have been added with this THIBAUT Pilot such as configuration and control of tools according to materials, machining simulation, a library of parametric shapes.

It is possible to prepare the programs on a computer (software T’Cut, eT’cam…) or directly at the machine.

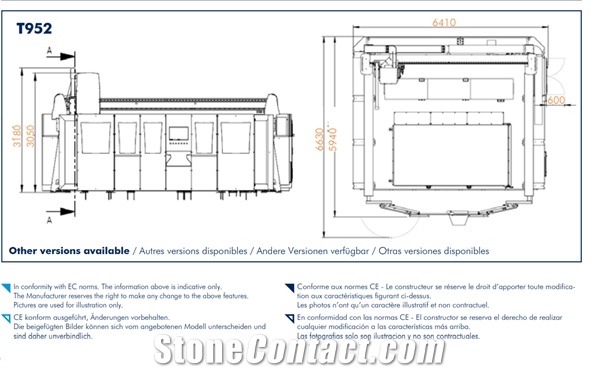

Technical Data

Parameters |

Unit |

T952 |

Machine overall height |

mm |

3050 |

Approx. Weight |

Kg |

10700 |

X axis stroke |

mm |

3970 (or 3750*) |

Air consumption |

m3/h |

12 ( 6 bar) |

Machine overall length |

mm |

5940 |

Tool-holder spindle rotation speed |

r/min |

0 to 10 000 |

Total Power required |

kw |

34 |

Dimensions of the work table (length x width) |

mm |

3650 x 2200 |

Y axis stroke |

mm |

3700 |

Z axis stroke |

mm |

500 |

Machine overall width |

mm |

6430 |

Water requirement |

L/min |

40 |

Tool-holder spindle motor power |

kw |

18 |

Recommended CNC Working Center Products

Baptiste Lebouteiller

Baptiste Lebouteiller