Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesWaterjet Machines

4000*2000mm profect waterjet laser message marble cutting machine

FOB Price:$40000-60000

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesWaterjet Machines

Usage:

Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Lead Time:

30 days

Warranty:24 Months

Install and Guarantee:Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Field troubleshooting

Machinery Function Features

1.37KW SIEMENS motor

2.All electric components are Schneider brand

3.Can do special size and special design according to customer’s demand

4.Free abrasive sand feeding system

5.We have most convenient automatic abrasive sand removing and recycling system for any brand water jet cutting machine

6.Imported intensifier pump

7.Use 8mm steel to make the cutting table stronger and keep the precision time for whole life

8.Soft cover for linear guider or gear and rack, can effectively prevent dust

9.Install an automatic oil tank for cutting table , no need maintenance of linear guider

10.Legitimate WINDOWS 7 system and install the Chinese newest water jet cutting system

2.All electric components are Schneider brand

3.Can do special size and special design according to customer’s demand

4.Free abrasive sand feeding system

5.We have most convenient automatic abrasive sand removing and recycling system for any brand water jet cutting machine

6.Imported intensifier pump

7.Use 8mm steel to make the cutting table stronger and keep the precision time for whole life

8.Soft cover for linear guider or gear and rack, can effectively prevent dust

9.Install an automatic oil tank for cutting table , no need maintenance of linear guider

10.Legitimate WINDOWS 7 system and install the Chinese newest water jet cutting system

Technical Data

Parameters |

Unit |

WMT4020 |

X - Y axis displacement speed |

m/min |

50 |

Machine length (L) |

mm |

4200 |

Main Power |

kW |

37 |

Machine width (W) |

mm |

2200 |

Approximate weight(including table) |

Kg |

4500 |

Machine height (H) |

mm |

2000 |

Max. working slab thickness(marble/granite) |

mm |

200 |

Power |

V |

220v/380v/415v |

Maximum depth of cutting |

mm |

200 |

Dimensions of the work table |

mm |

4000x2000 |

Software

Control system

Adopt industrial PC:

Dedicated water jet cutting software with graphic simulation running function, graphic input automatic programming function. • Support for DXF files. • Support forward and reverse processing functions. • Uniform speed control function. • Two modes of segmentation and smooth machining. • Automatic processing with small arc speed. • Coordinate recovery function after power off. • Double lift speed parameter function. • With cycle processing. • Convenient pause to continue and start machining in any segment. • Free time delay setting. • Apply SIEMENS PLC instead of relay, buttons are Schneider.

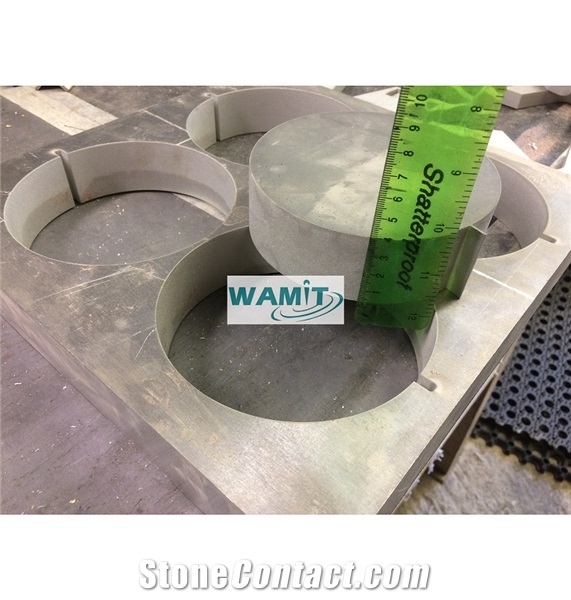

Work Example

ADVANTAGES:

1. we promise 2 years( 2000 hours) warranty always. and have got CE certificate

2. we use flow type ECL cutting head, the cutting efficiency is at least 10% higher.

3. the abrasive sand hopper beside the cutting head is also FLOW design.

4. we have new technology that can make the machine moving speed is to 30m/min. normal speed is 6m/min as you see. if this

technology used in pure water cutting, the cutting cost will reduce 50%. if using other materials cutting like glass , marble,

steel, the cutting cost will also 20-30% reduced. but of course , the machine with this function price will be a little higher.

5. we use soft cover of the linear guider, can prevent dust away from the linear guider, so keep the linear guider keep precision

longer.

6. we assemble an auto oil feeding to linear guider, so customer needn't maintenance the linear guider always.

7. seperated body.

8. we will send a remote control pendent.

9. we have the world most convenient abrasive sand removing system. it can be used for any brand water jet cutting machine, maybe

you can promote this system in your country and other countries. please check the attachment.

11. we supply 420mpa pump with 37KW motor, but the price of the whole machine is very competitive now

12. we use variable pump, so can reduce electricity cost for customers.

13. we can do 220V and 415v also.

14. like height tracking system, positioning system , we can also provide.

15. all our components are SCHNEIDER brand

16. the motor and PLC are SIEMENS brand.

17. we can provide AB 5 axis with 10 degree and AC 3D 5 axis with 60 degree.

18. use 10mm steel for water tank supporter and use 8mm steel for beam, keep the machine working more stable.

19. use JAPAN YASKAWA servo motor.

20. imported TAIWAN HIWIN ball screw and linear guider

21. imported America intensifier and TAIWAN accumulator and high pressure assembly and low pressure assembly. if you have special

requests, we can also do.

22. we can provide 80Kpsi and 90KPSI intensifier pump and 60KPSI direct drive pump.

23. can make Touch screen

24. automatic calibration gantry perpendicularity

Can nearly cut all material:

Alloy Steel

Aluminum

Armor Plate

Brass

Boron

Bronze

Cast Iron

Cobalt

Copper

Exotic Alloys

Hastalloy

Hardened Steel

Hot Rolled Steel

Inconel

Kevlar

Magnesium

Mild Steel

Nickel AlloysStainless Steel

Steel Alloy

Steel Hardened

Steel Hard Rolled

Steel Mild

Steel Tool

Tantalum

Tin

Titanium

Tungsten

Wrought Iron

Zinc

Acrylics

Ceramics

Composites

Foam

Fiberglass

Kevlar

Mylar Laminates

Nylon

Plastics

Plexiglass

Porcelain

PVC

Rubber

Thermoplastics

Teflon

Urethane

Vinyl

Armor Plate

Bullet Proof Glass

Glass,Mirror Glass

Ceramic Tile

Granite

Limestone

Marble

Porcelain

Terrazzo

Hardwood

1. we promise 2 years( 2000 hours) warranty always. and have got CE certificate

2. we use flow type ECL cutting head, the cutting efficiency is at least 10% higher.

3. the abrasive sand hopper beside the cutting head is also FLOW design.

4. we have new technology that can make the machine moving speed is to 30m/min. normal speed is 6m/min as you see. if this

technology used in pure water cutting, the cutting cost will reduce 50%. if using other materials cutting like glass , marble,

steel, the cutting cost will also 20-30% reduced. but of course , the machine with this function price will be a little higher.

5. we use soft cover of the linear guider, can prevent dust away from the linear guider, so keep the linear guider keep precision

longer.

6. we assemble an auto oil feeding to linear guider, so customer needn't maintenance the linear guider always.

7. seperated body.

8. we will send a remote control pendent.

9. we have the world most convenient abrasive sand removing system. it can be used for any brand water jet cutting machine, maybe

you can promote this system in your country and other countries. please check the attachment.

11. we supply 420mpa pump with 37KW motor, but the price of the whole machine is very competitive now

12. we use variable pump, so can reduce electricity cost for customers.

13. we can do 220V and 415v also.

14. like height tracking system, positioning system , we can also provide.

15. all our components are SCHNEIDER brand

16. the motor and PLC are SIEMENS brand.

17. we can provide AB 5 axis with 10 degree and AC 3D 5 axis with 60 degree.

18. use 10mm steel for water tank supporter and use 8mm steel for beam, keep the machine working more stable.

19. use JAPAN YASKAWA servo motor.

20. imported TAIWAN HIWIN ball screw and linear guider

21. imported America intensifier and TAIWAN accumulator and high pressure assembly and low pressure assembly. if you have special

requests, we can also do.

22. we can provide 80Kpsi and 90KPSI intensifier pump and 60KPSI direct drive pump.

23. can make Touch screen

24. automatic calibration gantry perpendicularity

Can nearly cut all material:

Alloy Steel

Aluminum

Armor Plate

Brass

Boron

Bronze

Cast Iron

Cobalt

Copper

Exotic Alloys

Hastalloy

Hardened Steel

Hot Rolled Steel

Inconel

Kevlar

Magnesium

Mild Steel

Nickel AlloysStainless Steel

Steel Alloy

Steel Hardened

Steel Hard Rolled

Steel Mild

Steel Tool

Tantalum

Tin

Titanium

Tungsten

Wrought Iron

Zinc

Acrylics

Ceramics

Composites

Foam

Fiberglass

Kevlar

Mylar Laminates

Nylon

Plastics

Plexiglass

Porcelain

PVC

Rubber

Thermoplastics

Teflon

Urethane

Vinyl

Armor Plate

Bullet Proof Glass

Glass,Mirror Glass

Ceramic Tile

Granite

Limestone

Marble

Porcelain

Terrazzo

Hardwood

More advantages

1. Automatic lubrication system from the Valley of Japan.

2. The internal components are selected from Schneider International brand, with first-class quality and reliable work.

3. Way of drive : Servo ( drives and motors are from Japan YASKAWA ).

4. High precision, Ensure cutting results.

5. Provide customizable services.

6. After-sales Service: Field maintenance and repair service, Online support, Field installation, commissioning and training, Video technical support, Free spare parts.

HP servo direct drive pump

WAMIT servo direct drive pump represents a new generation of high-efficiency, energy-saving ultra-high pressure pump, which is the first large R&D in China. Servo motor driven direct drive intensifier system.

Power is only 15kw, which can save you 60% to 70% of the cost

Model: WMT SDD 20

Maximum pressure: 60000Psi.

Gemstone aperture: 0.33mm.

Displacement: 3.0 l/min.

Inlet pressure: 0.4MPa.

Main motor power: 15KW.

Dimensions: 1680*900*1100mm

Double row water filtration system (5Micron, 1micron, series)

Intelligent start and stop function.

Over-pressure automatic shutdown and under-pressure automatic protection.

Advantages of the WAMIT servo direct drive pump:

A: Energy saving: The main motor adopts a torque motor of 15KW, compared with the motor of the 37KW hydraulic high pressure intensifier system, the power consumption can be saved by 60%-70%. B: Environmental protection: the use of servo direct drive, no hydraulic system, with self-cooling function. As we all know, hydraulic The hydraulic intensifier system must be filled with 110L of anti-wear hydraulic oil to work, and the heat generated by the hydraulic oil is also cooled by the oil cooler. The direct drive pump is completely free of hydraulic oil and cooling system. C: High efficiency: Direct drive pump provides a higher pressure output ratio, cutting speed is 20 to 50% faster than the same equipment in the market. E: Low noise: almost no noise when working. F: Small weight: The total weight of the direct drive pump is less than 600kg, and the movement is flexible. The weight of the hydraulic intensifier pump is 1000kg. G: Beautiful appearance: The structure is reasonable in design and beautiful in appearance, because the direct drive pump does not have a hydraulic system, Thereby avoiding the leakage of the hydraulic oil (the hydraulic seal will be damaged for a long time use, causing the hydraulic oil to leak), eliminates the contamination of equipment by oil stains.

Control system

Adopt industrial PC

Dedicated water jet cutting software with graphic simulation running function, graphic input automatic programming function. • Support for DXF files. • Support forward and reverse processing functions. • Uniform speed control function. • Two modes of segmentation and smooth machining. • Automatic processing with small arc speed. • Coordinate recovery function after power off. • Double lift speed parameter function. • With cycle processing. • Convenient pause to continue and start machining in any segment. • Free time delay setting. • Apply SIEMENS PLC instead of relay, buttons are Schneider.

Abrasive feeder

• 170 liter capacity • High-precision sensors alert operators when they need to replenish sand • Safety relief valve • Working pressure: 0.2-0.3MPa • Water separator

can use 8-10 hours.

No need electronic control, simple operation, reliable, maintenance-free. Can supply the cutting sand quantity . Need less than 0.2Mpa compressed gas pressure. Provide sand storage for the water jet cutter and automatically transfer the sand to the sand bucket. Can increase the automation of the equipment and reduce the labor intensity of the operator.

3D AC 5 axis cutting head

1.The cutting resultis much better. When cuttingshaped sharp corners or continuous sharp corners, there is no obvious zero point

at the corners2.A wide range of processes. It can makecylindrical parquet, large angle chamfer and other drawing which AB

five-axis waterjet can not be completed3.High processing efficiency. The C axis rotates infinitely, and the corner speed is fast,

which improves the processing efficiency.

at the corners2.A wide range of processes. It can makecylindrical parquet, large angle chamfer and other drawing which AB

five-axis waterjet can not be completed3.High processing efficiency. The C axis rotates infinitely, and the corner speed is fast,

which improves the processing efficiency.

AB 5 AXIS

flip table

laser height tracking system

Water softener

oil chiller

remote controller

Cutting Speed

Cutting speed | Materials | Thinkness | Cutting Speed of direct drive pump (mm/min) | Cutting Speed of 420MPa(mm/min) |

Marble | 25 | 1000 | 800 | |

30 | 800 | 600 | ||

Microcrystal stone | 16 | 1200 | 900 | |

Ceramic tile | 12 | 2000 | 1500 | |

14 | 1400 | 900 | ||

Glass | 5 | 2000 | 1600 | |

8 | 1800 | 1400 | ||

10 | 1500 | 1100 | ||

12 | 1200 | 900 | ||

14 | 1000 | 700 | ||

Carbon Steel plate | 10 | 330 | 270 | |

12 | 280 | 220 | ||

14 | 240 | 180 | ||

16 | 200 | 140 | ||

20 | 170 | 110 | ||

22 | 140 | 85 | ||

Aluminum | 12 | 800 | 600 | |

30 | 200 | 160 |

Our cutting sample

Our Customer

About company

Shandong WAMI CNC Technology Co.,Ltd.

Shandong WAMIT CNC Technology Co., Ltd is a professional manufacturer of water jet cutting machine. We are specialized in R&D, manufacturing, sales and technical services of ultra high pressure water jet cutting systems and relative parts. We have 3 axis, 5 axis water jet cutting machine and have 60000psi, 80000psi , 90000psi intensifier pum and drect drive pump. Our water jet cutting machine is widely used in stone industry, glass industry, metal industry, composite materials(plastic, rubber, acrylic, foam), food industry and so on.

The company's products are exported to Europe, America, Africa, Asia and so on, and gradually establish a relationship from high quality, high quality, high service to trust.

Packaging & Shipping

Recommended Waterjet Machines Products

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Waterjet Machines

Granite Waterjet Machines

Marble Waterjet Machines

Limestone Waterjet Machines

Slate Waterjet Machines

Onyx Waterjet Machines

Artificial Stone Waterjet Machines

Basalt Waterjet Machines

Quartzite Waterjet Machines

Sandstone Waterjet Machines

Travertine Waterjet Machines

Wamit Machines

Linda Lee

Linda Lee