Home ProductsStone MachineryStone Factory MachinesStone Block Cutting MachinesCNC Diamond Wire Shaping Machine

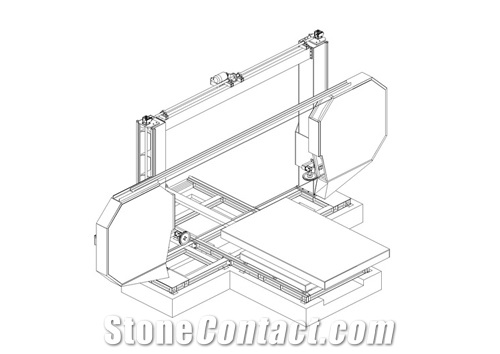

SNM-WI-2J Single Wire (2 Mt) Block Cutting Machine, CNC Diamond Wire Shaping Machine

FOB Price:

Type:

Stone Factory MachinesStone Block Cutting MachinesCNC Diamond Wire Shaping Machine

Usage:

Marble, Limestone, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Remote troubleshooting, Field troubleshooting

Supplier

Eatablished :Jan 01,1962

Main Product:

Stone Machinery, Cutting Machines, Polishing Machines|

Contact supplier

You may also like

Machinery Function Features

The technology:

Wire cutting machines are increasingly used for block cutting, mainly in hard stone, and for automatic cutting of curved shapes ( profiling and contouring ). They are based on a system of axes, each with a specific function. Each machine is equipped with a PC-based CNC which runs all system operations and manages the axes movements.

Main benefits of wire cutting:

Although tool costs for wire machines are still currently greater than those for the cutting wheel, the signs are reversed in terms of energy cost: wire machines have distinctly lower power consumption and the high cutting speed also partly compensates for the higher tool costs.

Because the wire is constantly in contact with the stone to be cut, the speed advantage is up to 30 percent depending on the material and the wire condition.

Types of wire cutting machines:

Our range of wire cutting machines includes 4 types:

The 2-axis

The 2-axis jumbo

The 4-axis

The 6-axis

Axis X: horizontal trolley movement

Axis Y and V: vertical independent movements for the columns

Axis B: 360-degrees rotating table

Axis C and Q: rotating heads

The 2 and 4 axis models will provide the same cutting and contouring possibilities but the 4-axis works faster.

The main advantage of the 6-axis model is that it can cut helicoidal, conical and asymmetrical shapes thanks to its fully computerized 6 axis ECS CNC system which controls 6 brushless AC servo motors.

Features:

A PC-based CNC operates the entire system and manages the axes movements. The general management program includes fixed cycles and special executions. The input of data is very easy and the system allows for a graphic simulation of the profile,also showing the path of the tool. The starting point of the operations is from a block with automatic repositioning and the resolution of the tangential connections is done automatically. A RS-232 connector and a printer plug are installed on board.

The inverter allows for a variety of wire speeds and the cutting of both marble and granite at optimum speeds.

Pneumatic wire tensioning system

CAD-CAM Alphacam

The wheel covers are made of aluminum composite panels and their structure is stainless steel. The stainless steel strip around the wheels prevents the diamond rope from getting tangled in the wheel in case it breaks.

All covers are in stainless steel.

The guides on the column are in stainless steel, hardened and then covered with hard chrome.

All axes are equipped with high precision ball-screw assembly

Wire cutting machines are increasingly used for block cutting, mainly in hard stone, and for automatic cutting of curved shapes ( profiling and contouring ). They are based on a system of axes, each with a specific function. Each machine is equipped with a PC-based CNC which runs all system operations and manages the axes movements.

Main benefits of wire cutting:

Although tool costs for wire machines are still currently greater than those for the cutting wheel, the signs are reversed in terms of energy cost: wire machines have distinctly lower power consumption and the high cutting speed also partly compensates for the higher tool costs.

Because the wire is constantly in contact with the stone to be cut, the speed advantage is up to 30 percent depending on the material and the wire condition.

Types of wire cutting machines:

Our range of wire cutting machines includes 4 types:

The 2-axis

The 2-axis jumbo

The 4-axis

The 6-axis

Axis X: horizontal trolley movement

Axis Y and V: vertical independent movements for the columns

Axis B: 360-degrees rotating table

Axis C and Q: rotating heads

The 2 and 4 axis models will provide the same cutting and contouring possibilities but the 4-axis works faster.

The main advantage of the 6-axis model is that it can cut helicoidal, conical and asymmetrical shapes thanks to its fully computerized 6 axis ECS CNC system which controls 6 brushless AC servo motors.

Features:

A PC-based CNC operates the entire system and manages the axes movements. The general management program includes fixed cycles and special executions. The input of data is very easy and the system allows for a graphic simulation of the profile,also showing the path of the tool. The starting point of the operations is from a block with automatic repositioning and the resolution of the tangential connections is done automatically. A RS-232 connector and a printer plug are installed on board.

The inverter allows for a variety of wire speeds and the cutting of both marble and granite at optimum speeds.

Pneumatic wire tensioning system

CAD-CAM Alphacam

The wheel covers are made of aluminum composite panels and their structure is stainless steel. The stainless steel strip around the wheels prevents the diamond rope from getting tangled in the wheel in case it breaks.

All covers are in stainless steel.

The guides on the column are in stainless steel, hardened and then covered with hard chrome.

All axes are equipped with high precision ball-screw assembly

Technical Data

Parameters |

Unit |

SNM-WI-2J |

Number of brushless motor |

nr |

2 |

Diamond wire length |

m |

20.50 |

Wire actuating motor power |

hp |

20 |

Block max. widht |

mm |

2000 |

2 flywheels diameter (each) |

mm |

2000 |

Block length |

mm |

3500 |

Block-holding trolley dimensions |

mm |

3000x2000 |

4 wire control flywheels diameter (each) |

mm |

350 |

Wire-driving unit rotation |

° |

90 |

Block max. height |

mm |

2000 |

Related Products:

Machinery

Factory Machines

Stone Block Cutting Machines

Cnc Diamond Wire Shaping Machine

Granite Cnc Diamond Wire Shaping Machine

Marble Cnc Diamond Wire Shaping Machine

Limestone Cnc Diamond Wire Shaping Machine

Sandstone Cnc Diamond Wire Shaping Machine

Travertine Cnc Diamond Wire Shaping Machine

Snic Machines

Kamal K. Nahas

Kamal K. Nahas