Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

fully automated edge-polishing machine

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Usage:

Granite, Marble

Machinery Function Features

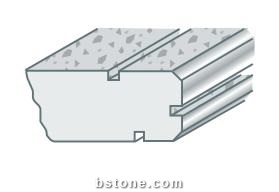

A result of many years of CMG experience, the Taurus 565 is a fully automated edge-polishing machine that, thanks to its dimensions, adapts itself to any space, and is a valid alternative for the craftsman and small and medium-sized factories.

The heart of the machine’s functional advantage is the rotation system which was developed in 1984 and rened further over the years by using harder and more resistant steel.

Compared to their competitors, CMG implements an avant-garde design and decides to increase the thickness of the working bench from 17 to 22mm. This means more stability, safety, and increased durability. The frame of the new Taurus 565 is made of electro-welded steel and is protected by industrial-grade paint. It is also covered by stainless steel protections.Thanks to its versatility, the Taurus 565 is able to range from a simple staircase step to a kitchen countertop with extreme ease! The Taurus 565 is the fruit of long research and technological studies. It provides to the user a control panel mounted on a swivel-arm placed conveniently in a place for the operator where it can be accessed from any point along the machine’s working area! The control panel has an easy-to-operate 6” digital coloured touch-screen which is also easily programmed!

The heart of the machine’s functional advantage is the rotation system which was developed in 1984 and rened further over the years by using harder and more resistant steel.

Compared to their competitors, CMG implements an avant-garde design and decides to increase the thickness of the working bench from 17 to 22mm. This means more stability, safety, and increased durability. The frame of the new Taurus 565 is made of electro-welded steel and is protected by industrial-grade paint. It is also covered by stainless steel protections.Thanks to its versatility, the Taurus 565 is able to range from a simple staircase step to a kitchen countertop with extreme ease! The Taurus 565 is the fruit of long research and technological studies. It provides to the user a control panel mounted on a swivel-arm placed conveniently in a place for the operator where it can be accessed from any point along the machine’s working area! The control panel has an easy-to-operate 6” digital coloured touch-screen which is also easily programmed!

Technical Data

Parameters |

Unit |

TAURUS 565 |

Approx. Weight |

Kg |

5000 |

Max. processing thickness |

mm |

60 |

Total power |

kW |

30 |

Machine overall length |

mm |

5000 |

Min. processing width |

mm |

180 |

Belt advancement speed |

mm/min |

5/2300 |

Min. processing thickness |

mm |

15 |

Max. diameter of calibrating wheel |

mm |

200 |

Machine overall height |

mm |

2000 |

Diameter of the drip board saw blade |

mm |

300 |

Front spindles |

nr |

6 |

Machine overall width |

mm |

1800 |

Water consumption |

m3/h |

5.4 |

Number of Bevelling/chamfering spindles |

nr |

2/4 |

Video

Operation Video

Screen.PrimaryScreen.Bounds.Height

Recommended Edge Profiling, Polishing Machine Products

Gabriele Cordioli

Gabriele Cordioli