CNC 5 Axis Stone Cutting And Milling Machine Bridge Saw For Marble

FOB Price:$35500-37500

2)Easy to use interface with 17" color touch-screen. 3)The machine is equipped with an industrial computer, embedded touch screen, supports CAD file import.

4)The machine adopts integrated structure, the frame and beam are welded by high-quality carbon steel plate and profiles, solid and reliable, high stability. 5)The X-axis lateral movement adopts servo motor + high-precision planetary reducer + linear guide rail, and then with high-precision helical rack and pinion drive. 6).Y-axis longitudinal movement adopts double servo motor + high-precision planetary reducer + linear guide rail, and then with high-precision helical rack and pinion drive; 7).The Z-axis main machine lifting adopts servo motor + high-precision planetary reducer + linear guide rail, and then with high-precision ball screw drive. 8).A-axis head tilt rotation 0-90° and C-axis head plane rotation 0-360° are driven by servo motor + precision robot RV reducer, supporting five-axis linkage, high dimensional precision and shape precision.

9)Working platform can tilt 85 degrees, easy for slabs loading.

10)Milling cutter function(standard).

11)Suction cup function(optional).

12)Thickness measurement function(optional).

Parameters |

Unit |

CNC450-5 |

A-axis rotation |

64 |

0~90 |

Diameter of the blades that can be applied |

4 |

450 |

Max. length of the cut slab |

4 |

3200 |

Overall machine length |

4 |

5800 |

Average level of equivalent sound power |

66 |

80 |

Max. workable thickness with blade or waterjet |

4 |

150 |

C-axis rotation |

64 |

0~360 |

Overall machine height |

4 |

3000 |

Overall machine width |

4 |

3400 |

Z-axis travel |

4 |

300 |

Max. width of the cut slab |

4 |

2000 |

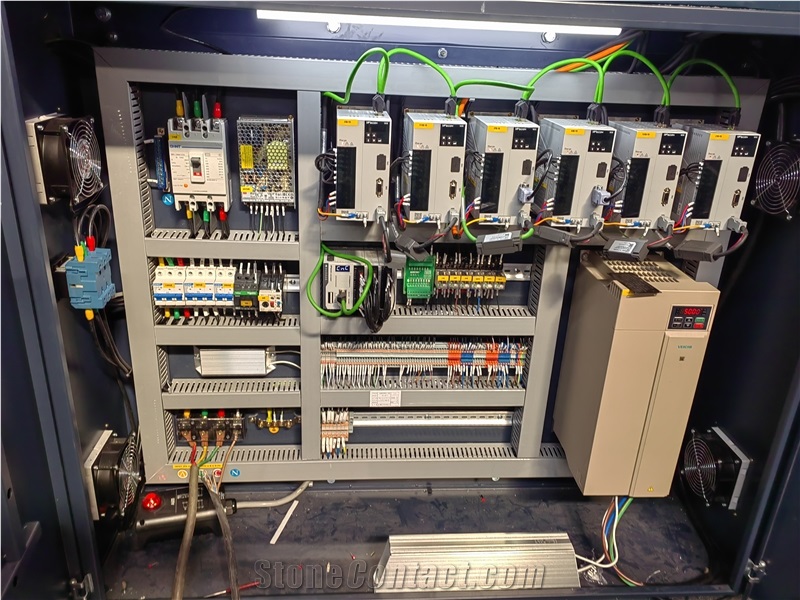

CNC control system. The machine is equipped with an industrial computer, an embedded touch screen, supports CAD file import, is equipped with a vision system, and is equipped with a high-definition industrial-grade camera to take pictures of the plates to be processed on the machine, automatically locate the position of the plates, and automatically generate programs through the intelligent system to cut the work;

The machine adopts integrated structure, the frame and beam are welded by high-quality carbon steel plate and profiles, solid and reliable, high stability; The Z-axis main machine lifting adopts servo motor + high-precision planetary reducer + linear guide rail, and then with high-precision ball screw drive. The X-axis lateral movement adopts servo motor + high-precision planetary reducer + linear guide rail, and then with high-precision helical rack and pinion drive. Y-axis longitudinal movement adopts double servo motor + high-precision planetary reducer + linear guide rail, and then with high-precision helical rack and pinion drive; A-axis head tilt rotation 0-90° and C-axis head plane rotation 0-360° are driven by servo motor + precision robot RV reducer, supporting five-axis linkage, high dimensional precision and shape precision.

The machine is equipped with an industrial computer, an embedded touch screen, supports CAD file import, automatically generate programs through the intelligent system to cut the work;

The worktable can be turned over, and the turning plate is driven by double hydraulic cylinders. The oil circuit accessories are made of well-known brands in Taiwan and equipped with double-layer thickened high-pressure tubing.

Related Products:

3YR

3YR

Frank Chow

Frank Chow