Home ProductsStone MachineryStone Factory MachinesResin Line MachinesProtective Polymer Applicator for Slabs

Breton APP - Polymer Applicator For slab polishing lines

FOB Price:

Type:

Stone Factory MachinesResin Line MachinesProtective Polymer Applicator for Slabs

Usage:

Granite, Marble, Limestone

After-Sale

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Online software upgrade, Regular guidance & maintenance

Trade Terms

Delivery Details: FOB

Payment :

Supplier

Breton S.p.A.

Italy

Italy

Eatablished :Dec 31,1962

Main Product:

Stone Machines, Cutting Machine, Polising Machine, Wire Saw, Cnc Machines|

Contact supplier

You may also like

Machinery Function Features

Breton APP - POLYMER APPLICATOR For slab polishing lines

Contact us!

If you want to be contacted, fill in the following form.

APP - POLYMER APPLICATOR FOR SLAB POLISHING LINES

The Polymer Applicator (APP) is a cost efficient and environmentally sustainable method for protecting polished surfaces of slabs when they are stacked in “packs” and when being handled and moved.

WHAT IS BRETON APP?

Breton APP is a specific system mounted just before the automatic slab discharge unit at the end of the polishing line. It is designed to apply dots or lines of a thermoplastic polymer.

The number, the interval between dots/lines and form can be programmed to specific requirements. This polymer has been developed and formulated to protect the polished surface of slabs when they are stacked in “packs” in the warehouse and when being handled.

APP is an alternative system to the conventional polythene film offering the advantage of not having to deal with waste treatment and relative costs.

The polymer is purchased in granules in drums of 25 kg.

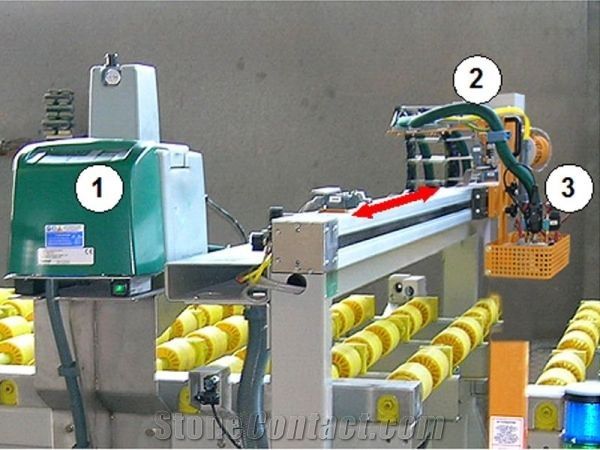

The granules are heat melted in the purpose container (1) and the melted polymer is conveyed along the heated piping (2) to the extruder gun which is also heated (3) and moves transversally.

The extruder gun, depending on the form programmed, deposits dots or lines of melted polymer on the polished surface of the slab. The polymer instantly cools down and solidifies when it comes into contact with the cold slab and remains bonded to the surface.

Contact us!

If you want to be contacted, fill in the following form.

APP - POLYMER APPLICATOR FOR SLAB POLISHING LINES

The Polymer Applicator (APP) is a cost efficient and environmentally sustainable method for protecting polished surfaces of slabs when they are stacked in “packs” and when being handled and moved.

WHAT IS BRETON APP?

Breton APP is a specific system mounted just before the automatic slab discharge unit at the end of the polishing line. It is designed to apply dots or lines of a thermoplastic polymer.

The number, the interval between dots/lines and form can be programmed to specific requirements. This polymer has been developed and formulated to protect the polished surface of slabs when they are stacked in “packs” in the warehouse and when being handled.

APP is an alternative system to the conventional polythene film offering the advantage of not having to deal with waste treatment and relative costs.

The polymer is purchased in granules in drums of 25 kg.

The granules are heat melted in the purpose container (1) and the melted polymer is conveyed along the heated piping (2) to the extruder gun which is also heated (3) and moves transversally.

The extruder gun, depending on the form programmed, deposits dots or lines of melted polymer on the polished surface of the slab. The polymer instantly cools down and solidifies when it comes into contact with the cold slab and remains bonded to the surface.

Recommended Protective Polymer Applicator for Slabs Products

Stefano Titotto

Stefano Titotto