Home ProductsStone MachineryStone Factory MachinesStone Tile Cutting MachinesSingle Disc Cutting Machine

Tilbreton DAE - Automatic cutting machine

FOB Price:

Type:

Stone Factory MachinesStone Tile Cutting MachinesSingle Disc Cutting Machine

Usage:

Granite, Marble

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

Trade Terms

Delivery Details: FOB

Payment :

Supplier

Breton S.p.A.

Italy

Italy

Eatablished :Dec 31,1962

Main Product:

Stone Machines, Cutting Machine, Polising Machine, Wire Saw, Cnc Machines|

Contact supplier

Machinery Function Features

TILBRETON DAE - AUTOMATIC CUTTING MACHINE TO CUT THE LEADING/TRAILING EDGE OF STRIPS AND FOR THEIR DIMENSIONING

Fully automatic, this machine eliminates the need of the operator’s constant presence.

It can be easily programmed from a keyboard with monitor.

A series of motorized rubberized rollers and pressers guarantee the correct advancement of the strips so as to assure the feeding of the cutting area.

An encoder measuring the material feed and reading tracer points guarantee the cutting dimensions. The machine is equipped with centring strip-guides, adjustable through a handwheel.

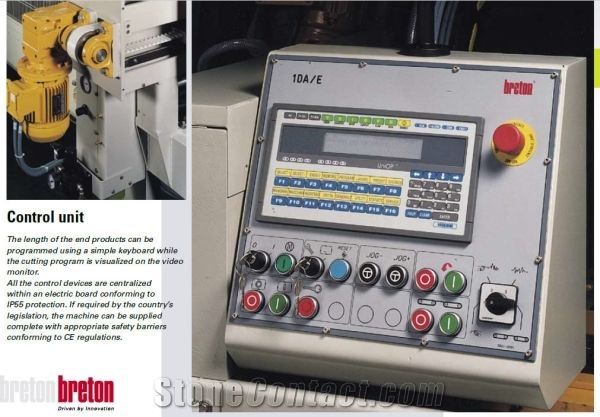

CONTROL UNIT

The length of the end products can be programmed using a simple keyboard while the cutting program is visualized on the video monitor.

All the control devices are centralized within an electric board conforming to IP55 protection. If required by the country’s legislation, the machine can be supplied complete with appropriate safety barriers conforming to CE regulations.

SPINDLE UNIT

The diamond blade-holding spindle unit is mounted on a cast-iron trolley running along the rectified guides ofthe bridge on ball-bearing slides. The movement of the spindle-holding trolley is obtained by means of a geared belt and a reduction gear unit with inverter, which makes it possible to adjust the cutting advancement according to the type and thickness of the material to be processed.

The sliding system is lubricated in an oil bath and protected by stainless steel labyrinth seal covers.The spindle unit has pneumatic vertical exclusion: after cutting has been carried out, the spindle unit raises automatically before reaching the starting position, while securing the following strip positioning.

Fully automatic, this machine eliminates the need of the operator’s constant presence.

It can be easily programmed from a keyboard with monitor.

A series of motorized rubberized rollers and pressers guarantee the correct advancement of the strips so as to assure the feeding of the cutting area.

An encoder measuring the material feed and reading tracer points guarantee the cutting dimensions. The machine is equipped with centring strip-guides, adjustable through a handwheel.

CONTROL UNIT

The length of the end products can be programmed using a simple keyboard while the cutting program is visualized on the video monitor.

All the control devices are centralized within an electric board conforming to IP55 protection. If required by the country’s legislation, the machine can be supplied complete with appropriate safety barriers conforming to CE regulations.

SPINDLE UNIT

The diamond blade-holding spindle unit is mounted on a cast-iron trolley running along the rectified guides ofthe bridge on ball-bearing slides. The movement of the spindle-holding trolley is obtained by means of a geared belt and a reduction gear unit with inverter, which makes it possible to adjust the cutting advancement according to the type and thickness of the material to be processed.

The sliding system is lubricated in an oil bath and protected by stainless steel labyrinth seal covers.The spindle unit has pneumatic vertical exclusion: after cutting has been carried out, the spindle unit raises automatically before reaching the starting position, while securing the following strip positioning.

Technical Data

Parameters |

Unit |

Tilbreton DAE |

Machine height (H) |

mm |

2000 |

Machine length (L) |

mm |

3500 |

Maximum cutting width |

mm |

640 |

Forwarding/Spindle motor power |

kW |

7.5 |

Machine width (W) |

mm |

2100 |

Minimum strip length |

mm |

1200 |

Approximate weight |

kg |

2050 |

Disc/Spindle travelling speed |

m/min |

0÷16 |

Discs number |

nr |

1 |

Disc motor power |

kW |

7.5 |

Cooling water (minimum pressure 1.5 bar) |

l/min |

15 |

Discs diameter |

mm |

350 |

Average level of sound power |

dbA |

89.5 |

Maximum workable thickness |

mm |

40 |

Acustic power level |

dbA |

107 |

Oleodynamic station motor power |

kW |

0.75 |

Recommended Single Disc Cutting Machine Products

Stefano Titotto

Stefano Titotto