Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesStone Carving Robot

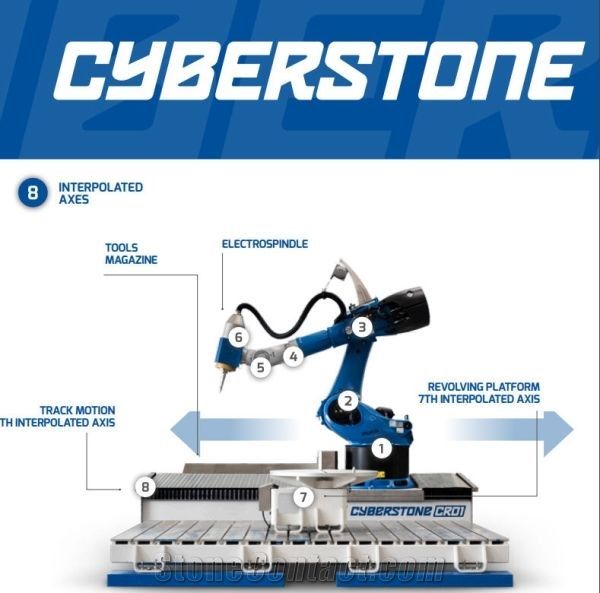

Cyberstone CR01/CR02 Stone Carving Robot

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesStone Carving Robot

Usage:

Granite, Limestone, Onyx, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Online software upgrade, Regular guidance & maintenance

Machinery Function Features

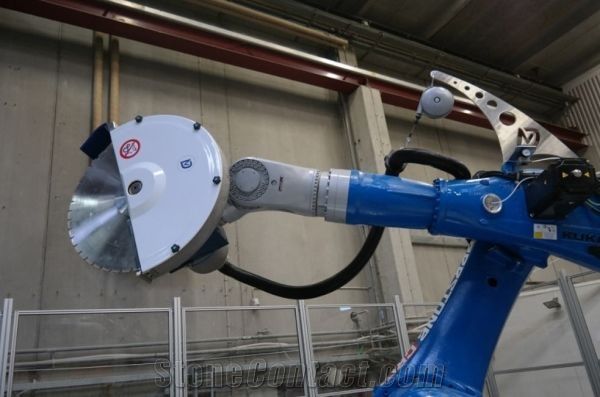

Cyberstone is the new generation robotized production system with 6/7/8 interpolated axes, designed to be a highly flexible tool for the performance of elements and objects of any size and material with heights up to 3300 mm. It is particularly suitable for sculptures, rectilinear, concave, convex, arched, elliptic shapes, single or incremental pass and excavations of two-dimensional and three-dimensional section blocks; it is also suitable for the execution of oblique, circular, elliptical cuts, inclined up to a thickness of 260 mm. Thanks to the rotating platform, it is possible to work the piece at 360 ° without moving or repositioning it for the working shots. Its mobile arm with 6 interpolated axes allows to perform 180 ° undercuts; the ISO 50 connection allows the use of diamond tools of different types, such as drills, grinding wheels, wheels for rebates, finger bits, shaping tips and cutting discs with diameter 650 or 850 mm.

This robot allows to make extremely precise finishing and to create sinks, tubs, tables, chairs, shower trays, vases, statues, columns and other architectural elements in general. CYBERSTONE meets the most demanding requirements, maximizes productivity, and, thanks to the numerous accessories, can be set up as a working center for single pieces of any size or for mass production.

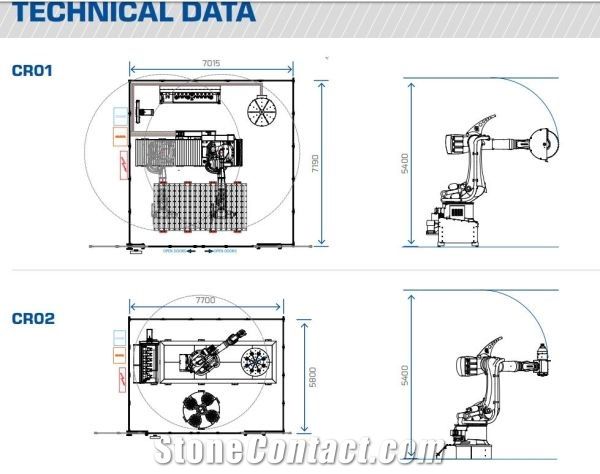

CR01

Cyberstone CR01 is the optimal version to carry out complex large operations. The track motion allows to manage multiple work stations so making the machine extremely flexible. It can be combined with the fixed aluminum platform or the new Multiplate Revolver platform.

Technical data:CR01

- 6 interpolated axes + 2

- Maximum range of action: 3300 mm

- Working angle: + - 185°

- Positioning repeatability + - 0.08 mm

Endowment:

- Cyberstone Robot (6 interpolated axes)

- Track Motion system (7th axis interpolated) -

dimensions: 4350 x 2090 mm

- Interpolated rotating table (8 axis interpolated) -

dimensions: diameter 1200 x h 715 mm

- Tool storage 10 positions – ISO 50

- SmartPad

CR02

Cyberstone CR02 is the most compact

configuration of the Cyberstone range;

equipped with monoblock with rotating

platform, it allows to work pieces of various

sizes. Installation and transport are fast

and do not require foundations. It can be

combined with the fixed aluminum platform

or the new Multiplate Revolver platform.

Technical data:CR02

- 6 interpolated axes + 1

- Maximum range of action: 3300 mm

- Working angle: + - 185°

- Positioning repeatability + - 0.08 mm

Endowment:

- Cyberstone Robot (6 interpolated axes)

- Monoblock frame

dimensions: 6740mm x 2250 mm

- Interpolated rotating table (7 axis interpolated)

dimensions: diameter 1400 x h 715 mm

- Tool storage 10 p

This robot allows to make extremely precise finishing and to create sinks, tubs, tables, chairs, shower trays, vases, statues, columns and other architectural elements in general. CYBERSTONE meets the most demanding requirements, maximizes productivity, and, thanks to the numerous accessories, can be set up as a working center for single pieces of any size or for mass production.

CR01

Cyberstone CR01 is the optimal version to carry out complex large operations. The track motion allows to manage multiple work stations so making the machine extremely flexible. It can be combined with the fixed aluminum platform or the new Multiplate Revolver platform.

Technical data:CR01

- 6 interpolated axes + 2

- Maximum range of action: 3300 mm

- Working angle: + - 185°

- Positioning repeatability + - 0.08 mm

Endowment:

- Cyberstone Robot (6 interpolated axes)

- Track Motion system (7th axis interpolated) -

dimensions: 4350 x 2090 mm

- Interpolated rotating table (8 axis interpolated) -

dimensions: diameter 1200 x h 715 mm

- Tool storage 10 positions – ISO 50

- SmartPad

CR02

Cyberstone CR02 is the most compact

configuration of the Cyberstone range;

equipped with monoblock with rotating

platform, it allows to work pieces of various

sizes. Installation and transport are fast

and do not require foundations. It can be

combined with the fixed aluminum platform

or the new Multiplate Revolver platform.

Technical data:CR02

- 6 interpolated axes + 1

- Maximum range of action: 3300 mm

- Working angle: + - 185°

- Positioning repeatability + - 0.08 mm

Endowment:

- Cyberstone Robot (6 interpolated axes)

- Monoblock frame

dimensions: 6740mm x 2250 mm

- Interpolated rotating table (7 axis interpolated)

dimensions: diameter 1400 x h 715 mm

- Tool storage 10 p

Technical Data

Parameters |

Unit |

CR01 / CR02 |

Max. range of action |

mm |

3326 |

A3 speed with nominal payload |

degree/s |

70°/s |

Machine overall width |

mm |

7015 |

Spindle tool holder type |

ISO 50 |

|

A1 speed with nominal payload |

degree/s |

80° /s |

Class of protection of the central wrist |

IP 67 |

|

Installed power |

kW |

30 |

A6 speed with nominal payload |

degree/s |

110°/s |

A6 interpolated axes |

° |

±350° |

Spindle nominal power |

kW |

28/S6 |

Maximum cutting depth |

mm |

260 |

Protection class |

IP 65 |

|

A2 speed with nominal payload |

degree/s |

75°/s |

Repeatability of positioning |

mm |

±0,08 |

A3 interpolated axes |

° |

-100° / 144° |

A5 interpolated axes |

° |

±120° |

A4 speed with nominal payload |

degree/s |

70°/s |

Spindle disk max. diameter |

mm |

825 |

Speed rotation max. |

rpm |

6000 |

Standard voltahe/Nominal tension |

Volt |

400 |

A2 interpolated axes |

° |

-130° / 20° |

Control system |

KR C4 |

|

A5 speed with nominal payload |

degree/s |

70°/s |

Weight (robots only) |

Kg |

2686 |

Spindle disk min. diameter |

mm |

350 |

Machine overall height |

mm |

5400 |

A4 interpolated axes |

° |

±350° |

Number of interpolated axes |

nr |

6/7/8 |

Water consumption |

l/min |

3 - 50 |

A1 interpolated axes |

° |

±185° |

Weight capacity on the wirst |

kg |

420 |

Machine overall length |

mm |

7190 |

Air consumption |

m3/h |

6 - 20 |

Components

Luca Donatoni

Luca Donatoni