Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

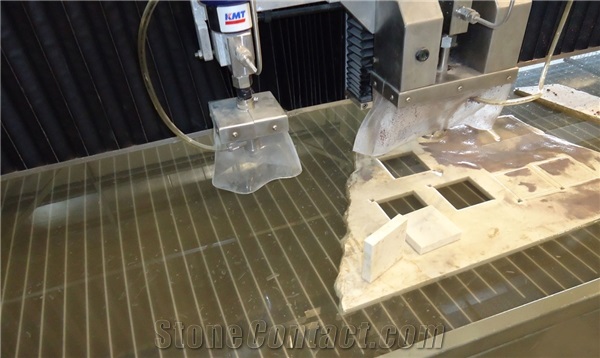

NEW RIO 3 CNC Waterjet Machine

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

Usage:

Granite, Marble, Limestone, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Online software upgrade, Regular guidance & maintenance

Machinery Function Features

Waterjet machines NEW RIO, 3 or 5 axis, are designed and built to cut any type of material: marble, granite, artificial quartz, ceramic, any type of stone, glass, rubber, plastic, steel, aluminum, brass and other.

Powered by a numerical control interfaced with CAD/CAM systems and by a dedicated software WJ CAM, they allow to get precise cuts without thermal deformations.

Whether for the production of unique pieces or for serial production waterjet machines NEW RIO are ideal for straight, inclined and shaped cuts, as well to create inlays.

Powered by a numerical control interfaced with CAD/CAM systems and by a dedicated software WJ CAM, they allow to get precise cuts without thermal deformations.

Whether for the production of unique pieces or for serial production waterjet machines NEW RIO are ideal for straight, inclined and shaped cuts, as well to create inlays.

Technical Data

Parameters |

Unit |

NEW RIO 3 |

NEW RIO 3 with 2 cutting heads |

Machine overall length |

mm |

5.820 |

5.820 |

Approx. Weight |

Kg |

5.000 |

5.000 |

Sound pressure level |

dB |

80 ÷ 85 |

80 ÷ 85 |

Y axis stroke |

mm |

2.000 |

2.000 |

Y axis rapid speed |

m/min |

60 |

|

Max total absorbed power – Pump 40HP |

kW |

29 |

37 |

Z axis stroke |

mm |

180 |

180 |

Machine overall height |

mm |

2.200 - 3.500(with hp pipe) |

2.200 - 3.500(with hp pipe) |

Max total absorbed power – Machine |

kW |

5,5 |

5,5 |

Capacity of abrasive container |

kg |

425 |

425 |

X axis stroke |

mm |

4.000 |

4.000 |

X axis rapid speed |

m/min |

60 |

|

Z axis rapid speed |

m/min |

15 |

|

Machine overall width |

mm |

3.500 |

3.500 |

Software

Powered by a numerical control interfaced with CAD/CAM systems and by a dedicated software WJ CAM, they allow to get precise cuts without thermal deformations.

Recommended CNC Working Center Products

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Cnc Working Center

Granite Cnc Working Center

Marble Cnc Working Center

Limestone Cnc Working Center

Onyx Cnc Working Center

Artificial Stone Cnc Working Center

Basalt Cnc Working Center

Quartzite Cnc Working Center

Sandstone Cnc Working Center

Travertine Cnc Working Center

Prussiani Machines

Mario Giorgio Prussiani

Mario Giorgio Prussiani