Home ProductsStone MachineryStone Factory MachinesStone Block Cutting MachinesGiant Disc Bridge Saw Machine

Automatic cycle machine Pedrini M950EF-Giant disc bridge saw

FOB Price:

Type:

Stone Factory MachinesStone Block Cutting MachinesGiant Disc Bridge Saw Machine

Usage:

Granite, Marble, Limestone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Remote troubleshooting, Field troubleshooting

You may also like

Machinery Function Features

This AUTOMATIC CYCLE machine, that was designed for the sawing of 1000 max. high blocks, is targeted to the production of large thickness slabs for tombstone art, building elements and paving stones.

The axis positioning is ensured by a PLC controlled system that comprises electronic vector regulators (inverters) and position digital transducers (encoders).

Disc down feed can be programmed during last phase of each cutting stroke thus permitting stroke immediate reciprocation and consequent “PENDULAR” motion that eliminates unproductive time.

The machine is equipped with VANISHING DISC that reduces noise level in any working position. Owing to the components high quality, to the sturdiness and precision of the mechanical parts, M950EF is an highly productive and reliable machine that maintains its great efficiency in time.

Two large contact surface “V” guides, machined onto the bridge, allow for trolley clearance- free sliding driven by a rack/pinion system.

Anti friction slides between trolley and bridge and continuous lubrication oil pits cut along the “V” guides enable the trolley stroke to be smooth and without vibrations even in case of high travelling speed.

Contrasting wheels, that compact trolley and bridge, allow discharging of the cutting stress directly onto the foundations.

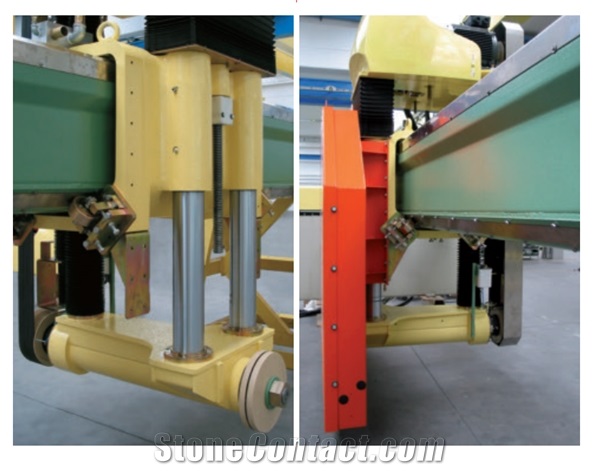

The disc holder unit comprises an upper platform for main motor mounting and the spindle assembly that are connected to form a sole body through three ground chrome plated large diameter columns that slide vertically into protected housings machined onto trolley structure.

The two columns in front position absorb longitudinal stress caused by cutting action and improve disc performance.

Vertical displacement is driven in a balanced way through two synchronized screw/lead nut systems motioned by encoder controlled gear motor.

Bridge moves along two track ways fixed onto foundations. Bridge transversal displacement is driven through two rack/pinion systems that are synchronized through a connecting shaft motioned by an encoder equipped and inverter adjusted speed gear motor.

Bridge sliding along track ways is guided through two pairs of bearing wheels, with large centreline distance (1200 mm), that ensure bridge stability.

A system of auxiliary contrast wheels reacts to all vertical stress and allows for a very smooth disc performance。

The axis positioning is ensured by a PLC controlled system that comprises electronic vector regulators (inverters) and position digital transducers (encoders).

Disc down feed can be programmed during last phase of each cutting stroke thus permitting stroke immediate reciprocation and consequent “PENDULAR” motion that eliminates unproductive time.

The machine is equipped with VANISHING DISC that reduces noise level in any working position. Owing to the components high quality, to the sturdiness and precision of the mechanical parts, M950EF is an highly productive and reliable machine that maintains its great efficiency in time.

Two large contact surface “V” guides, machined onto the bridge, allow for trolley clearance- free sliding driven by a rack/pinion system.

Anti friction slides between trolley and bridge and continuous lubrication oil pits cut along the “V” guides enable the trolley stroke to be smooth and without vibrations even in case of high travelling speed.

Contrasting wheels, that compact trolley and bridge, allow discharging of the cutting stress directly onto the foundations.

The disc holder unit comprises an upper platform for main motor mounting and the spindle assembly that are connected to form a sole body through three ground chrome plated large diameter columns that slide vertically into protected housings machined onto trolley structure.

The two columns in front position absorb longitudinal stress caused by cutting action and improve disc performance.

Vertical displacement is driven in a balanced way through two synchronized screw/lead nut systems motioned by encoder controlled gear motor.

Bridge moves along two track ways fixed onto foundations. Bridge transversal displacement is driven through two rack/pinion systems that are synchronized through a connecting shaft motioned by an encoder equipped and inverter adjusted speed gear motor.

Bridge sliding along track ways is guided through two pairs of bearing wheels, with large centreline distance (1200 mm), that ensure bridge stability.

A system of auxiliary contrast wheels reacts to all vertical stress and allows for a very smooth disc performance。

Technical Data

Parameters |

Unit |

M950EF-D250 |

Disc cutting speed ( X axis) |

m/min |

0,8/14 |

Max. cutting depth |

mm |

1000 |

Cut/return stroke ( X axis) |

mm |

3700 |

Machine width |

mm |

6700 |

Cut/return motor power |

kw |

2,2 |

Bridge displacement motor power |

kw |

1.5 |

Bridge displacement speed (Y axis) |

m/min |

5 |

Bridge transversal stroke (Y axis) |

mm |

4000 |

Disch vertical stroke ( Z axis) |

mm |

1100 |

Installed power |

kw |

50 |

Vertical displacement motor power |

kw |

1.5 |

Machine height |

mm |

5610 |

Vertical displacement speed (Z axis) |

m/min |

0,4 |

Machine length(front) |

mm |

8000 |

Approximate Weight |

Kg |

10600 |

Vertical disc motor power |

kw |

45 |

Cooling water (1.5 bar pressure) |

L/min |

80 |

Vertical disc diameter |

mm |

2500 |

Recommended Giant Disc Bridge Saw Machine Products

Related Products:

Machinery

Factory Machines

Stone Block Cutting Machines

Giant Disc Bridge Saw Machine

Granite Giant Disc Bridge Saw Machine

Marble Giant Disc Bridge Saw Machine

Limestone Giant Disc Bridge Saw Machine

Basalt Giant Disc Bridge Saw Machine

Quartzite Giant Disc Bridge Saw Machine

Sandstone Giant Disc Bridge Saw Machine

Travertine Giant Disc Bridge Saw Machine

Pedrini Machines

Giambattista Pedrini

Giambattista Pedrini