Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

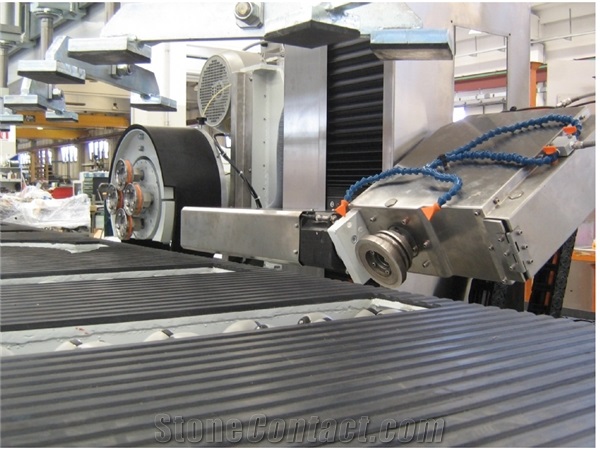

Comandulli ATHENA Single-head profile-edge polishing machine with bench for Flat and round profiles

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Usage:

Granite, Marble, Limestone, Basalt, Quartzite, Sandstone

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Remote troubleshooting, Field troubleshooting

Machinery Function Features

Edge polishing machines with bench

Very versatile machines able to work single pieces or small series of pieces; they allow you to obtain a very good quality on every type of straight and round edge.

Suitable for FURNISHING and MONUMENTS, they can be used in high quality BUILDING field as well, with a middle/high production.

ATHENA: by itself, it works for three.

Single-head profile-edge polishing machine, highly innovative for marble, granite and stone edge working products. Multipurpose and diverse machine, produced to assist all stone masonry requirements, from monumental processing through to furnishing and architectural work. Machine constructed using mechanichal components of high-precision utilizing industrial technological advances, minimizing complexity, thus producing a thoroughly user friendly environment, together with reduced maintenance requirements. Dedicated electronic equipment permits every typeof processing through very simple, fast and completely automated procedures.

Treatment against corrosion by means of metallization; covers in stainless steel or sumbitted to cataphoresis treatment

Features

THE EXCLUSIVE FEATURES OF A COMANDULLI MACHINE ATHENA

Monobloc machine constructed with ultimately strong and rigid chassis, produced through high-quality and high-precision mechanical systems. The retaining-spindle slide moves along the frontal side of the working surface by means of ball screws guides, managed by a brushless motor.

Electrical tool retaining spindle (4 kW) with variable speed range from 0 to 3000 rpm, assembled on three monitored and interpolated axes, also managed by brushless motors. Vertical axis stroke (ball screws guides): 550 mm. Horizontal axis stroke (ball screws guides): 250 mm.

Rotation axis stroke 180°.

Machine frame metallized and submitted to cataphoresis treatment.

Main covers in stainless steel.

EQUIPMENTS

THE UNIQUE PLEASURE OF SEEING YOUR IDEAS, EVEN THE MOST CREATIVE, COMING TRUE.

By using the Athena machine you will be able to realize the most common profiles available on the market and create customized ones, even with various shapes or heights..

12 positions automatic tool change.

CNC control unit, together with controls visualized on touch-screen monitor.

Workpiece loading system by means of a pneumatic turntable.

Pneumatic holding-slab pistons.

Reference squares for piece alignment.

Centralized automatic lubrication.

Sensor for the automatic reading of piece position.

Automatic device which stops the machine in event of exhausted abrasive tools.

Water circuit with sensor for automatic machine stop in case of lack of water.

Software with pre-set profiles.

Flexibility to program and work at the same time 5 pieces with different thickness and profile.

External wire-net fencing for the operator safety.

Very versatile machines able to work single pieces or small series of pieces; they allow you to obtain a very good quality on every type of straight and round edge.

Suitable for FURNISHING and MONUMENTS, they can be used in high quality BUILDING field as well, with a middle/high production.

ATHENA: by itself, it works for three.

Single-head profile-edge polishing machine, highly innovative for marble, granite and stone edge working products. Multipurpose and diverse machine, produced to assist all stone masonry requirements, from monumental processing through to furnishing and architectural work. Machine constructed using mechanichal components of high-precision utilizing industrial technological advances, minimizing complexity, thus producing a thoroughly user friendly environment, together with reduced maintenance requirements. Dedicated electronic equipment permits every typeof processing through very simple, fast and completely automated procedures.

Treatment against corrosion by means of metallization; covers in stainless steel or sumbitted to cataphoresis treatment

Features

THE EXCLUSIVE FEATURES OF A COMANDULLI MACHINE ATHENA

Monobloc machine constructed with ultimately strong and rigid chassis, produced through high-quality and high-precision mechanical systems. The retaining-spindle slide moves along the frontal side of the working surface by means of ball screws guides, managed by a brushless motor.

Electrical tool retaining spindle (4 kW) with variable speed range from 0 to 3000 rpm, assembled on three monitored and interpolated axes, also managed by brushless motors. Vertical axis stroke (ball screws guides): 550 mm. Horizontal axis stroke (ball screws guides): 250 mm.

Rotation axis stroke 180°.

Machine frame metallized and submitted to cataphoresis treatment.

Main covers in stainless steel.

EQUIPMENTS

THE UNIQUE PLEASURE OF SEEING YOUR IDEAS, EVEN THE MOST CREATIVE, COMING TRUE.

By using the Athena machine you will be able to realize the most common profiles available on the market and create customized ones, even with various shapes or heights..

12 positions automatic tool change.

CNC control unit, together with controls visualized on touch-screen monitor.

Workpiece loading system by means of a pneumatic turntable.

Pneumatic holding-slab pistons.

Reference squares for piece alignment.

Centralized automatic lubrication.

Sensor for the automatic reading of piece position.

Automatic device which stops the machine in event of exhausted abrasive tools.

Water circuit with sensor for automatic machine stop in case of lack of water.

Software with pre-set profiles.

Flexibility to program and work at the same time 5 pieces with different thickness and profile.

External wire-net fencing for the operator safety.

Technical Data

Parameters |

Unit |

Athena |

Dressing/polishing spindle power |

kw |

4 |

Max. diameter of shaping wheel |

mm |

100 ÷ 160 |

Total power |

kw |

14 |

Calibrating spindle rotation speed |

r/min |

0 ÷ 3000 |

Polishing spindle rotation speed |

r/min |

0 ÷ 3000 |

Spindle horizontal axis speed |

m/1' |

0 ÷ 20 |

Bevelling /Chamfering spindle power |

kw |

4 |

Linear tools Diameter dimension |

mm |

100 ÷ 160 |

Standard diameter of polishing wheels |

mm |

100 ÷ 160 |

Standard diameter of chamfering wheels |

mm |

100 ÷ 160 |

Machine overall height |

mm |

2200 |

Spindle Vertical axis speed |

m/1' |

0 ÷ 20 |

Max. processing thickness |

mm |

350 straight edge, 250 shaped edge |

Grinding spindle power |

kw |

4 |

Grinding tool diameter |

mm |

100 ÷ 160 |

Bevel tools Diameter dimension |

mm |

100 ÷ 160 |

Max. worktable width with fully extended hydraulic rod |

mm |

3500 |

Min. processing thickness |

mm |

10 |

Approx. Weight |

Kg |

5500 |

Machine overall width |

mm |

2300 |

Machine overall length |

mm |

7300 |

Spindle translation speed |

m/1' |

0 ÷ 100 |

Max. diameter of calibrating wheel |

mm |

100 ÷ 160 |

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Edge Profiling Polishing Machine

Granite Edge Profiling Polishing Machine

Marble Edge Profiling Polishing Machine

Limestone Edge Profiling Polishing Machine

Basalt Edge Profiling Polishing Machine

Quartzite Edge Profiling Polishing Machine

Sandstone Edge Profiling Polishing Machine

Comandulli Machines

Mara Comandulli

Mara Comandulli