Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

MGP/3 and MGP/5 - Automatic Machine for Steps and Edging

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Usage:

Granite, Marble, Limestone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Remote troubleshooting

You may also like

Machinery Function Features

NOVELTY

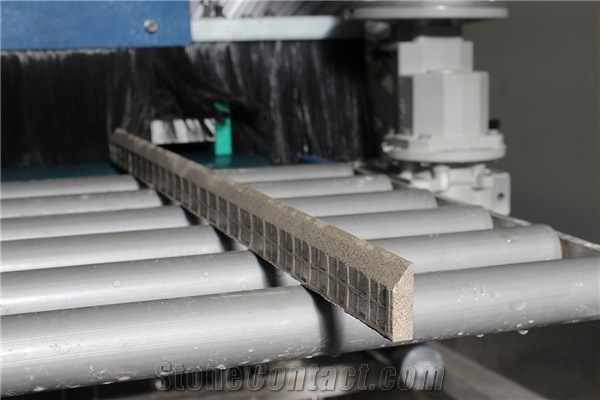

MGP/3 is the new automatic machine for steps and edging on ceramic, gres porcelain, marble, granite and agglomerate materials.

It is a revolutionary model that allows two different types of machining with just one automated, compact machine:

- a 45° bevel for creating steps.

- edging for skirting, doorsteps and window sills, with bullnose and half bullnose edges.

MGP/3 consists of 3 motor-spindles for tools, which can be angled to create a 45° bevel for steps or adjusted to an upright position for creating edges.

Available also in the five-head version to simultaneously operate five different grinding wheels and cut down working time.

MGP/5 is the new automatic machine for steps and edging on ceramic, gres porcelain, marble, granite and agglomerate materials.

It is a revolutionary model that allows two different types of machining with just one automated, compact machine:

- a 45° bevel for creating steps.

- edging for skirting, doorsteps and window sills, with bullnose and half bullnose edges.

MGP/5 consists of 5 motor-spindles for tools, which can be angled to create a 45° bevel for steps or adjusted to an upright position for creating edges.

MGP/5 allows to simultaneously operate five different grinding wheels and cut down working time.

MGP/3 is the new automatic machine for steps and edging on ceramic, gres porcelain, marble, granite and agglomerate materials.

It is a revolutionary model that allows two different types of machining with just one automated, compact machine:

- a 45° bevel for creating steps.

- edging for skirting, doorsteps and window sills, with bullnose and half bullnose edges.

MGP/3 consists of 3 motor-spindles for tools, which can be angled to create a 45° bevel for steps or adjusted to an upright position for creating edges.

Available also in the five-head version to simultaneously operate five different grinding wheels and cut down working time.

MGP/5 is the new automatic machine for steps and edging on ceramic, gres porcelain, marble, granite and agglomerate materials.

It is a revolutionary model that allows two different types of machining with just one automated, compact machine:

- a 45° bevel for creating steps.

- edging for skirting, doorsteps and window sills, with bullnose and half bullnose edges.

MGP/5 consists of 5 motor-spindles for tools, which can be angled to create a 45° bevel for steps or adjusted to an upright position for creating edges.

MGP/5 allows to simultaneously operate five different grinding wheels and cut down working time.

Technical Data

Parameters |

Unit |

MGP/3 |

MGP/5 |

Machine overall length |

mm |

2150 |

2150 |

Water consumption |

L/h |

200 |

200 |

Calibrating spindle rotation speed |

r/min |

2800 |

2800 |

Machine overall height |

mm |

1800 |

1800 |

Number of dressing/polishing spindles |

nr |

3 |

5 |

Voltage |

V/Hz |

400 V 50Hz |

400 V 50Hz |

Belt advancement power |

kw |

0,25 |

0,25 |

No. calibrating/shaping/cutting spindles |

nr |

3 |

5 |

Max. processing thickness |

mm |

20 |

30 |

Grinding tool diameter |

mm |

140 |

140 |

Conveyor Belt width |

mm |

350 |

350 |

Machine overall width |

mm |

3050 |

3850 |

Min. processing width |

mm |

30 |

30 |

Approx. Weight |

Kg |

600 |

800 |

Grinding spindle power |

kw |

2.2 |

2.2 |

Hydraulic pump power |

kw |

1x0,37 |

1x0,37 |

Number of Bevelling/chamfering spindles |

nr |

3 |

5 |

Polishing spindle rotation speed |

r/min |

2800 |

2800 |

Recommended Edge Profiling, Polishing Machine Products

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Edge Profiling Polishing Machine

Granite Edge Profiling Polishing Machine

Marble Edge Profiling Polishing Machine

Limestone Edge Profiling Polishing Machine

Basalt Edge Profiling Polishing Machine

Quartzite Edge Profiling Polishing Machine

Sandstone Edge Profiling Polishing Machine

Travertine Edge Profiling Polishing Machine

Compactline Machines

Luca Armagno

Luca Armagno