STENDHAL Auxiliary Machine for Polished Slab Lines

FOB Price:

Type:

Stone Factory MachinesStone Handling, Loading MachinesStone Scanner

Usage:

Granite, Marble, Limestone, Onyx, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Remote troubleshooting

Machinery Function Features

In line after the polishing machine, the slab passes over a synchronized roller conveyor through a special dark room where lighting system is perfectly controlled. A series of calibrated color references are used to adjust and control the perfect color rendering of the slab, making today the color measurable. This process takes a few seconds and does not impact in any way with the production flow.

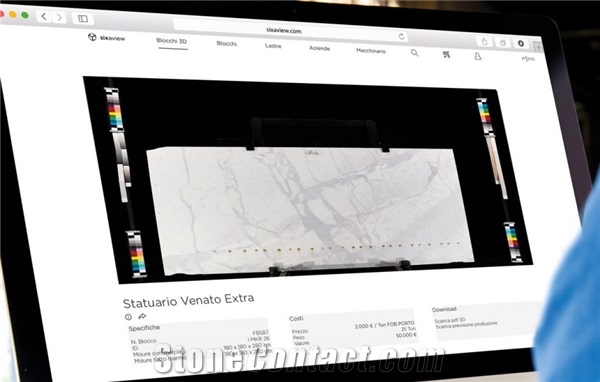

The high resolution image is immediately available, while the image analysis is carried out with a cloud server system. The chromatic model is suitable to be downloaded in streaming and for synchronization to the producer’s on-line store; it could as well be displayed in Sixaview web platform.

The new technology

1 – HD SHOOTING

The shooting process of the slab is carried out in a place ideal for perfectly capturing shape and colors and to enhance all its qualities. Each type of material, from whites to blacks, from beige to colored ones, can be shot with the automatic settings of the control system.

2 – TRUE COLORS AND MEASURABILITY

The dedicated software makes the surface virtually illuminated in an uniform way and color charts ensure that the tolerances relative to color measurements are very tight. In this way the slabs look “alive”, and the details turn amazing, allowing today to measure the color on a virtual slab model. The geometry is as well measurable.

3 – VIRTUAL 2D INSPECTION

It is possible to virtually inspect each slab: the operator shall be able to report hallmarks and defects using special software functions, so as to clarify the intrinsic characteristics of the utilized material and of the out-coming finishing. Inspection refers to an online library which is constantly updated.

4 – VIRTUAL 2D NESTING AND MOKE-UP

Specific nesting algorithms allow to optimize the exploitation of every single slab according to the bill of material of cut to size items, possibly avoiding or limiting the inclusion of defective material areas: the best possible positioning of the products to be cut within the usable area of the forecast slabs will be automatically calculated. The files obtained are available for those Architects who could be interested in a virtual moke-up.

The high resolution image is immediately available, while the image analysis is carried out with a cloud server system. The chromatic model is suitable to be downloaded in streaming and for synchronization to the producer’s on-line store; it could as well be displayed in Sixaview web platform.

The new technology

1 – HD SHOOTING

The shooting process of the slab is carried out in a place ideal for perfectly capturing shape and colors and to enhance all its qualities. Each type of material, from whites to blacks, from beige to colored ones, can be shot with the automatic settings of the control system.

2 – TRUE COLORS AND MEASURABILITY

The dedicated software makes the surface virtually illuminated in an uniform way and color charts ensure that the tolerances relative to color measurements are very tight. In this way the slabs look “alive”, and the details turn amazing, allowing today to measure the color on a virtual slab model. The geometry is as well measurable.

3 – VIRTUAL 2D INSPECTION

It is possible to virtually inspect each slab: the operator shall be able to report hallmarks and defects using special software functions, so as to clarify the intrinsic characteristics of the utilized material and of the out-coming finishing. Inspection refers to an online library which is constantly updated.

4 – VIRTUAL 2D NESTING AND MOKE-UP

Specific nesting algorithms allow to optimize the exploitation of every single slab according to the bill of material of cut to size items, possibly avoiding or limiting the inclusion of defective material areas: the best possible positioning of the products to be cut within the usable area of the forecast slabs will be automatically calculated. The files obtained are available for those Architects who could be interested in a virtual moke-up.

Recommended Stone Scanner Products

Carlo Belle

Carlo Belle