KEPLERO 3D Stone Blocks Evaluation System

FOB Price:

Type:

Stone Factory MachinesStone Handling, Loading MachinesStone Scanner

Usage:

Granite, Marble, Limestone, Onyx, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Remote troubleshooting

Machinery Function Features

KEPLERO is the revolutionary system to create and publish astonishing realistic 3D models of stone blocks, leaving no questions unattended about color nuances, shape and dimensions, fractures, hallmarks and defects.

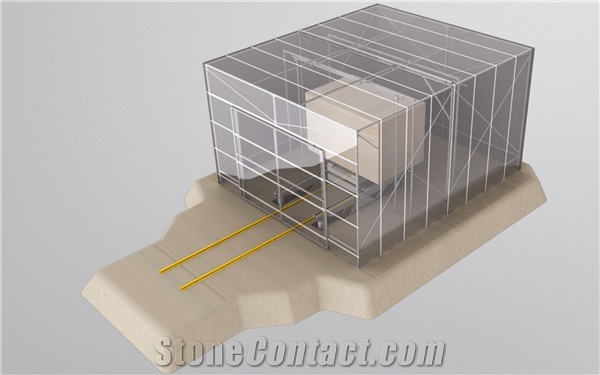

The system is based on a dark room and a roto-tilting device capable to properly and easily handle blocks up to 40 tons. Inside the room the lightening system is calibrated and controlled, so that the model creation is repeatable and constant.

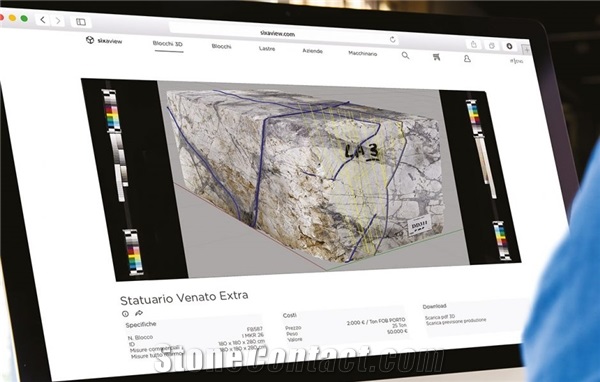

The elaboration is carried out with a cloud server system and the 3D model is suitable to be observed thanks to a special online viewer as well as a 3D pdf file. The model is also suitable for synchronization to the producer’s store on-line but it could be as well displayed in Sixaview web platform.

The new technology

1 – VIRTUAL 3D RENDERING

A reverse engineering process is applied, aiming to transform the physical block in an 3D virtual model, extremely faithful in geometry and color. The data acquisition takes place through a rigorous process of shooting of high resolution images on two orbital planes obtained by purposeful rotation and tilting of the block itself.

2 – VIRTUAL 3D INSPECTION

The 3D model of the block is such a realistic one to make possible today the virtual block inspection: the inspection quality is guaranteed by the possibility of fully observe the six faces of the block in details. Through dedicated algorithms the inspector can annotate directly on the virtual model the following points: fractures, holes, hallmarks and defects (about this, a specific library is online available and constantly updated).

3 – VIRTUAL 3D CUTTING

With the virtual block inspection it is possible to get the slabs outcome forecast by freely pre-determinate the following information set: position of the block in the cutting phase, face cutting start and step of the blades. The profile of each slab will result along with the intersection of eventual fractures and holes. The K% factor will summarize in a single numeric value the block’s output recovery.

4 – VIRTUAL 2D NESTING

Specific nesting algorithms allow to optimize the exploitation of every single slab according to the bill of material of cut to size items, possibly avoiding or limiting the inclusion of defective material areas: the best possible positioning of the products to be cut within the usable area of the forecast slabs will be automatically calculated.

The system is based on a dark room and a roto-tilting device capable to properly and easily handle blocks up to 40 tons. Inside the room the lightening system is calibrated and controlled, so that the model creation is repeatable and constant.

The elaboration is carried out with a cloud server system and the 3D model is suitable to be observed thanks to a special online viewer as well as a 3D pdf file. The model is also suitable for synchronization to the producer’s store on-line but it could be as well displayed in Sixaview web platform.

The new technology

1 – VIRTUAL 3D RENDERING

A reverse engineering process is applied, aiming to transform the physical block in an 3D virtual model, extremely faithful in geometry and color. The data acquisition takes place through a rigorous process of shooting of high resolution images on two orbital planes obtained by purposeful rotation and tilting of the block itself.

2 – VIRTUAL 3D INSPECTION

The 3D model of the block is such a realistic one to make possible today the virtual block inspection: the inspection quality is guaranteed by the possibility of fully observe the six faces of the block in details. Through dedicated algorithms the inspector can annotate directly on the virtual model the following points: fractures, holes, hallmarks and defects (about this, a specific library is online available and constantly updated).

3 – VIRTUAL 3D CUTTING

With the virtual block inspection it is possible to get the slabs outcome forecast by freely pre-determinate the following information set: position of the block in the cutting phase, face cutting start and step of the blades. The profile of each slab will result along with the intersection of eventual fractures and holes. The K% factor will summarize in a single numeric value the block’s output recovery.

4 – VIRTUAL 2D NESTING

Specific nesting algorithms allow to optimize the exploitation of every single slab according to the bill of material of cut to size items, possibly avoiding or limiting the inclusion of defective material areas: the best possible positioning of the products to be cut within the usable area of the forecast slabs will be automatically calculated.

Recommended Stone Scanner Products

Carlo Belle

Carlo Belle