Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

Taglio Frestag CAM for 3 and 3+2 axis CNC Stone Working Centers, Lathe Machines

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

Usage:

Granite, Marble, Limestone, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Remote guidance installation

Maintenance:Online software upgrade, Remote troubleshooting

Machinery Function Features

The CAM for 3-axis stoneworking centres and/or lathes

Frestag is the CAM suitable for 3-axes stone-working centres and more in general for the stone industry. The non-interpolated lathe machining is supported as well.

Focusing on the user-friendly aspect, it does not need particular IT skills and can been used from all the operators indistinctly. The user interface (UI) acts as a wizard, leading the user during the processing steps and reducing the probability of making errors during the programming phase.

DRAWING AND DESIGNING

Starting with the 2D entities of Logotag it is possible to reproduce:

sinks, quarries and pockets

mouldings and handrails

shower plates and drips

columns

Depending on the piece to reproduce, the users select the entities from the X-Y plane of the drawing (TAG, DWG, DXF) to import for Frestag.

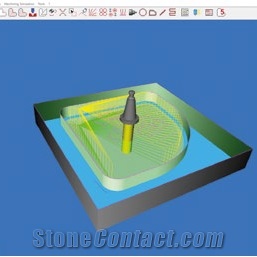

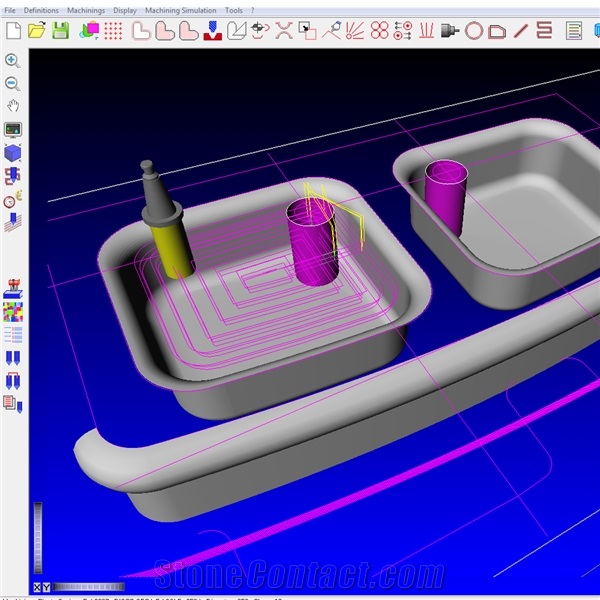

The graphic engine of Frestag is responsible for visualising the processing paths.

PROCESSES

Users can program different machining for:

3-axes profiles and contouring sections; roughing and polishing steps are available while tool sequences (e.g. 3 diamond tools + 3 polishing tools) allow the user to program the processes in few steps

quarry with a router bit and parallel or concentric passes

quarry with a blade tool and parallel passes

tapering for shower plates and similar

dripping for kitchen countertops

drilling

polishing

concave / convex machining

non-interpolated lathe

Taking this into account, if a specific part is to be made independently from the CNC machine, the functioning cycles are computed so that the software can be easily interfaced to multiple stone working centres. The post-processor translates all the processes in the proper language of the CNC to use to evaluate the CNC machine capabilities (e.g. automatic tool changer, rotating table, and aggregate head).

TOOLS

The tool database contains router bit (flat, bullnose, conical), shaped tools, blades, and aggregates.

Users can automatically or manually set the vacuums to lock the pieces.

Frestag is the CAM suitable for 3-axes stone-working centres and more in general for the stone industry. The non-interpolated lathe machining is supported as well.

Focusing on the user-friendly aspect, it does not need particular IT skills and can been used from all the operators indistinctly. The user interface (UI) acts as a wizard, leading the user during the processing steps and reducing the probability of making errors during the programming phase.

DRAWING AND DESIGNING

Starting with the 2D entities of Logotag it is possible to reproduce:

sinks, quarries and pockets

mouldings and handrails

shower plates and drips

columns

Depending on the piece to reproduce, the users select the entities from the X-Y plane of the drawing (TAG, DWG, DXF) to import for Frestag.

The graphic engine of Frestag is responsible for visualising the processing paths.

PROCESSES

Users can program different machining for:

3-axes profiles and contouring sections; roughing and polishing steps are available while tool sequences (e.g. 3 diamond tools + 3 polishing tools) allow the user to program the processes in few steps

quarry with a router bit and parallel or concentric passes

quarry with a blade tool and parallel passes

tapering for shower plates and similar

dripping for kitchen countertops

drilling

polishing

concave / convex machining

non-interpolated lathe

Taking this into account, if a specific part is to be made independently from the CNC machine, the functioning cycles are computed so that the software can be easily interfaced to multiple stone working centres. The post-processor translates all the processes in the proper language of the CNC to use to evaluate the CNC machine capabilities (e.g. automatic tool changer, rotating table, and aggregate head).

TOOLS

The tool database contains router bit (flat, bullnose, conical), shaped tools, blades, and aggregates.

Users can automatically or manually set the vacuums to lock the pieces.

Davide Beccaria

Davide Beccaria