Home ProductsStone MachineryStone Factory MachinesStone Slab Cutting MachinesMulti Blade Automatic Slab Cutting Line

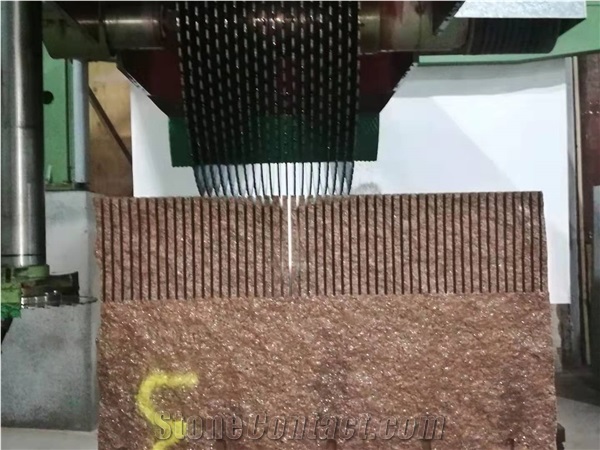

Multi-Blade Two-Way Cutting Machine

FOB Price:$52000-55000

Type:

Stone Factory MachinesStone Slab Cutting MachinesMulti Blade Automatic Slab Cutting Line

Usage:

Granite, Marble, Limestone, Slate, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Lead Time:

long time

Warranty:12 Months

Install and Guarantee:Customer pay for installation

Maintenance:Remote troubleshooting

Machinery Function Features

Infrared bridge cutting machine with 4-column adopts PLC control and automatic positioning techniques for various moves of the cutter frame & linear rolling guide driving,magnetic ruling,laser device setting.It is consists of high quality steel.The platform can be 360degree rotatable and automatically trun slate up.It can cut sizeable slabs with high precision and efficiency.

Technical parameters:

1•max.blade of diameter φ400-700mm

2•max.stroke for transverse 3600mm

3•max.stroke for longitudinal 3300mm

4.elevation stoke for main shaft of blade 430mm

5•max.titling degree for work-bench 87°

6•max.rotation degree for work-bench 360°

7.location degree for work-bench 0°- 45°- 90°

8•power of main motor 18.5kw

9•total power of machine 23.5kw

10•water consumption 2m3/h

11.water pressure >0.2 Mpa

12.overall size for machine 4800×5816×2350mm

13•total weight for machine 5800kg

This machine is composed of bridge stank, upper transmission unit,left and right moving mechanism, vertical arm, left and right side beam, block delivery trolley truck, and so on. The brief introduction to them as follows.The bridge stand is composed of bridge stand, sliding plates, spanning rack, fixing bush andhorizontal cutting, and so on. The cast bridge stand is supported by the rolling rail at the bottom end against right and left side beams. At its top, there is twin—V guides rail to act with sliding plate, guard is fitted over the guide rail to prevent dust intruding. The spanning rack is coupled with sliding plate, horizontal cutting tool is fitted at one side face of the spanning rack whose top is fitted with back bars reduction mechanism;gear;rank and bevel gear reducer;longitudinal moving motor. Vertical cutting tool is fitted at the bottom of bridge stand. When the machine cuts the blocks with vertical blade, the motor of vertical-cutting drives the blade to rotate through belt transmission and the slide plate moves longitudinally under the action of longitudinal moving motor through meshing between gear and rank. When the vertical cutting is completed and horizontal cutting begins, horizontal cutting blade carries on longitudinal lateral cutting which cuts off the plate and finishes the whole cutting operation. The height of horizontal blade could be adjusted by worm-wheel reduction box.The upper transmission part: This part consists of reducer motor, transmission shaft,connecting sleeve, bracket and bevel gear. When bridge stand elevates, the motion of motor for elevating is output from reducer motor through transmission shaft and bevel gear to lead screw which drives bridge stand to elevate.Left and right movement part: This part is composed of reducing gear, gear, spindle and splitwheel. When bridge stand moves, the motion of motor is transmitted to main gear which is engaged with the rack at the top of side beam and drives bridge frame to move to the right and the left. The amount of movement can be controlled by control panel.The vertical arms part: This part consists of four groups of vertical arms, two pieces at eachside and all are jointed with upper beam, left and right screw nut seat moves along the guide rails of vertical arm up and down, which makes bridge stand elevate.Left and right side beam part: This part is consist of left and right side beam, rack, slidingberth and screw nut seat. The left and right side beams are jointed with vertical arm by screw nut seat. At their top, there are rack and sliding berth assembly which is used to support bridge stand. The engagement space between rack and gear could be adjusted by reducer motor and bearing seat.Block delivery trolley truck part: It consists of reducing box, axle, chassis and track wheel,and so on. The truck is driven by independent motor. The chassis is made from profile steel and steel plate by means of welding. The motion of motor is reduced by reduction box and drives the wheel to rotate along guide rail, which carries out block conveying.

Technical parameters:

1•max.blade of diameter φ400-700mm

2•max.stroke for transverse 3600mm

3•max.stroke for longitudinal 3300mm

4.elevation stoke for main shaft of blade 430mm

5•max.titling degree for work-bench 87°

6•max.rotation degree for work-bench 360°

7.location degree for work-bench 0°- 45°- 90°

8•power of main motor 18.5kw

9•total power of machine 23.5kw

10•water consumption 2m3/h

11.water pressure >0.2 Mpa

12.overall size for machine 4800×5816×2350mm

13•total weight for machine 5800kg

This machine is composed of bridge stank, upper transmission unit,left and right moving mechanism, vertical arm, left and right side beam, block delivery trolley truck, and so on. The brief introduction to them as follows.The bridge stand is composed of bridge stand, sliding plates, spanning rack, fixing bush andhorizontal cutting, and so on. The cast bridge stand is supported by the rolling rail at the bottom end against right and left side beams. At its top, there is twin—V guides rail to act with sliding plate, guard is fitted over the guide rail to prevent dust intruding. The spanning rack is coupled with sliding plate, horizontal cutting tool is fitted at one side face of the spanning rack whose top is fitted with back bars reduction mechanism;gear;rank and bevel gear reducer;longitudinal moving motor. Vertical cutting tool is fitted at the bottom of bridge stand. When the machine cuts the blocks with vertical blade, the motor of vertical-cutting drives the blade to rotate through belt transmission and the slide plate moves longitudinally under the action of longitudinal moving motor through meshing between gear and rank. When the vertical cutting is completed and horizontal cutting begins, horizontal cutting blade carries on longitudinal lateral cutting which cuts off the plate and finishes the whole cutting operation. The height of horizontal blade could be adjusted by worm-wheel reduction box.The upper transmission part: This part consists of reducer motor, transmission shaft,connecting sleeve, bracket and bevel gear. When bridge stand elevates, the motion of motor for elevating is output from reducer motor through transmission shaft and bevel gear to lead screw which drives bridge stand to elevate.Left and right movement part: This part is composed of reducing gear, gear, spindle and splitwheel. When bridge stand moves, the motion of motor is transmitted to main gear which is engaged with the rack at the top of side beam and drives bridge frame to move to the right and the left. The amount of movement can be controlled by control panel.The vertical arms part: This part consists of four groups of vertical arms, two pieces at eachside and all are jointed with upper beam, left and right screw nut seat moves along the guide rails of vertical arm up and down, which makes bridge stand elevate.Left and right side beam part: This part is consist of left and right side beam, rack, slidingberth and screw nut seat. The left and right side beams are jointed with vertical arm by screw nut seat. At their top, there are rack and sliding berth assembly which is used to support bridge stand. The engagement space between rack and gear could be adjusted by reducer motor and bearing seat.Block delivery trolley truck part: It consists of reducing box, axle, chassis and track wheel,and so on. The truck is driven by independent motor. The chassis is made from profile steel and steel plate by means of welding. The motion of motor is reduced by reduction box and drives the wheel to rotate along guide rail, which carries out block conveying.

Technical Data

Parameters |

Unit |

GSD28 |

Load capacity |

Kg |

20000 |

Max. working slab thickness(marble/granite) |

mm |

8 |

Min. distance between the blades |

mm |

8 |

Overall machine length |

mm |

8360 |

Overall machine height |

mm |

6300 |

Overall machine width |

mm |

6470 |

Max./Min. blade diameter |

mm |

1650/1300 |

Machine weight |

Kg |

21 |

Max. length of slab |

mm |

3200 |

Max. distance between the blades |

mm |

610 |

Voltage |

Volt |

380V |

Spindle-holding beam motor power |

kw |

90 |

Shaft diameter of spindle motor |

mm |

100 |

Maximum depth of cutting |

mm |

650 |

Recommended Multi Blade Automatic Slab Cutting Line Products

Related Products:

Machinery

Factory Machines

Stone Slab Cutting Machines

Multi Blade Automatic Slab Cutting Line

Granite Multi Blade Automatic Slab Cutting Line

Marble Multi Blade Automatic Slab Cutting Line

Limestone Multi Blade Automatic Slab Cutting Line

Slate Multi Blade Automatic Slab Cutting Line

Onyx Multi Blade Automatic Slab Cutting Line

Artificial Stone Multi Blade Automatic Slab Cutting Line

Basalt Multi Blade Automatic Slab Cutting Line

Quartzite Multi Blade Automatic Slab Cutting Line

Sandstone Multi Blade Automatic Slab Cutting Line

Travertine Multi Blade Automatic Slab Cutting Line

Mountain Tigher Machines

monica bi

monica bi