Home ProductsStone MachineryStone Factory MachinesStone Block Cutting MachinesMulti Wire Saw Machine

Multi Wire Saw Granite Block Cutting Machine N6870/72

FOB Price:

Type:

Stone Factory MachinesStone Block Cutting MachinesMulti Wire Saw Machine

Usage:

Granite

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Remote troubleshooting, Field troubleshooting

Machinery Function Features

STRUCTURE AND DESIGN

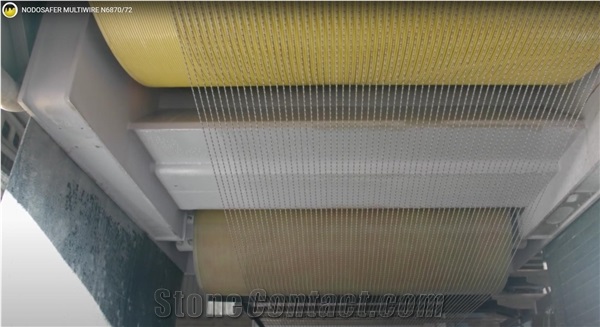

The Multiple Diamond Wire Cutter N.6870/72 is a multi-wire machine designed to produce slabs and plates of variable thickness from granite and natural stone blocks.

The structure of the machine is basically made up of two robust columns made up of mechanically-welded steel structures, connected to each other by an upper crossbar. The structure of the flywheel-carrying main frame is mounted on both columns, which moves vertically supported by linear guides with

recirculating linear roller skates and driven by a pair of laminated spindles with recirculating ball nuts, synchronized and driven by two motors. -reducers with servomotors for raising/lowering the wires, located in the upper part of both columns, the entire guide assembly is perfectly protected by PVC bellows.

The entire machine is characterized by the robustness and reliability of the elements that make it up, all of it being designed to withstand the harshest working conditions, and in this aspect it is precisely where we can contribute all the experience accumulated over the years that we have been designing and manufacturing machinery for this sector.

MOTOR DRUM AND TAMBORINOS

The driving drum is made up of a single pulley with multiple grooves and connected to the main motor by means of a pulley and toothed belt transmission. The wires are positioned manually depending on the desired thickness, supported on one side of the machine on the drive drum, and in turn are tensioned from the opposite end by autonomous pulleys.

The drums, like the drive drum, are vulcanized, which increases their useful life and allows continuous work on the machine without delaying tire change downtimes. A movement in both directions of the tambourines allows the channel to be changed quickly and efficiently in the event that

a channel is excessively worn or a thread has not worked effectively. This method contrasts significantly with the change of tires that exists in other types of equipment since it significantly reduces the maintenance of the machine and allows work to be resumed in a considerably shorter period of time.

TENSIONING SYSTEM

The STA is a combination of tensioning systems patented by NODOSAFER that allows the useful life of the threads to be increased, also increasing profitability and guaranteeing optimum surface finishes.

The tensioning is characterized by the individual control of the deflection of each one of the threads, allowing the machine to automatically detect the arc described at all times and tend to equalize the horizontality of all the threads, so that the times block cutting completion times decrease and the consumption of the machine is uniform and balanced. This system also increases the useful life of each thread since, as significant arcs are not formed, all the threads work in a similar way without supporting excessive tensions.

The diamond wires are also guided by two small multi-channel drums that help to significantly reduce the deflection produced by them.

The Cutter N.6870/72 allows to cut a maximum of 2000 mm wide at 21 mm thick, allowing to obtain 71 sheets.

SYSTEM OF PULLEYS, TENSION PULLEYS AND FREE PULLEYS

Innovative pulley system, with pivoting extraction system, which considerably reduces maintenance times. The pulley change is carried out quickly and efficiently without having to disassemble the entire assembly, thanks to their design since with a small maneuver the desired set of pulleys is disassembled in record time.

Once the threads are located, they are adjusted with the tensioning device that acts individually on each one

of the tensioning pulleys, independently ensuring that each one of the threads has the same tension

regardless of the minimum differences in length that exist between each one . one of the threads that are installed on the machine.

HAIR COMB

CONTROL PANEL AND ELECTRICAL PANEL

In the electrical and control installation section, it is worth highlighting the installation of state-of-the-art automatons with programs custom designed by our technicians, so that the programming of the machine is as simple as possible, thus avoiding losses of unnecessary time. The programming of the work cycle and the visualization of its sequence is carried out on an operator terminal with a screen, where all the parameters of the cutting cycle are displayed.

A very intuitive and visual display and a radio control complete the maneuverability of the machine as well as the comfort for the operator to carry out his work safely and precisely.

VERSATILITY

The design of the N6870/72 allows, for everything described above, that the operation of the machine by the customer is very simple and intuitive. Each of the required parameters is controlled from the screen and when changing the thickness to be cut, the simple programming of the display indicates the position of each thread on the pulleys and drums without the possibility of error.

SECURITY

NODOSAFER machines are protected by a security closure around their entire perimeter, complying with CE security regulations.

BLOCK TROLLEY

The machine has a motorized block carrier carriage incorporated as standard.

The Multiple Diamond Wire Cutter N.6870/72 is a multi-wire machine designed to produce slabs and plates of variable thickness from granite and natural stone blocks.

The structure of the machine is basically made up of two robust columns made up of mechanically-welded steel structures, connected to each other by an upper crossbar. The structure of the flywheel-carrying main frame is mounted on both columns, which moves vertically supported by linear guides with

recirculating linear roller skates and driven by a pair of laminated spindles with recirculating ball nuts, synchronized and driven by two motors. -reducers with servomotors for raising/lowering the wires, located in the upper part of both columns, the entire guide assembly is perfectly protected by PVC bellows.

The entire machine is characterized by the robustness and reliability of the elements that make it up, all of it being designed to withstand the harshest working conditions, and in this aspect it is precisely where we can contribute all the experience accumulated over the years that we have been designing and manufacturing machinery for this sector.

MOTOR DRUM AND TAMBORINOS

The driving drum is made up of a single pulley with multiple grooves and connected to the main motor by means of a pulley and toothed belt transmission. The wires are positioned manually depending on the desired thickness, supported on one side of the machine on the drive drum, and in turn are tensioned from the opposite end by autonomous pulleys.

The drums, like the drive drum, are vulcanized, which increases their useful life and allows continuous work on the machine without delaying tire change downtimes. A movement in both directions of the tambourines allows the channel to be changed quickly and efficiently in the event that

a channel is excessively worn or a thread has not worked effectively. This method contrasts significantly with the change of tires that exists in other types of equipment since it significantly reduces the maintenance of the machine and allows work to be resumed in a considerably shorter period of time.

TENSIONING SYSTEM

The STA is a combination of tensioning systems patented by NODOSAFER that allows the useful life of the threads to be increased, also increasing profitability and guaranteeing optimum surface finishes.

The tensioning is characterized by the individual control of the deflection of each one of the threads, allowing the machine to automatically detect the arc described at all times and tend to equalize the horizontality of all the threads, so that the times block cutting completion times decrease and the consumption of the machine is uniform and balanced. This system also increases the useful life of each thread since, as significant arcs are not formed, all the threads work in a similar way without supporting excessive tensions.

The diamond wires are also guided by two small multi-channel drums that help to significantly reduce the deflection produced by them.

The Cutter N.6870/72 allows to cut a maximum of 2000 mm wide at 21 mm thick, allowing to obtain 71 sheets.

SYSTEM OF PULLEYS, TENSION PULLEYS AND FREE PULLEYS

Innovative pulley system, with pivoting extraction system, which considerably reduces maintenance times. The pulley change is carried out quickly and efficiently without having to disassemble the entire assembly, thanks to their design since with a small maneuver the desired set of pulleys is disassembled in record time.

Once the threads are located, they are adjusted with the tensioning device that acts individually on each one

of the tensioning pulleys, independently ensuring that each one of the threads has the same tension

regardless of the minimum differences in length that exist between each one . one of the threads that are installed on the machine.

HAIR COMB

CONTROL PANEL AND ELECTRICAL PANEL

In the electrical and control installation section, it is worth highlighting the installation of state-of-the-art automatons with programs custom designed by our technicians, so that the programming of the machine is as simple as possible, thus avoiding losses of unnecessary time. The programming of the work cycle and the visualization of its sequence is carried out on an operator terminal with a screen, where all the parameters of the cutting cycle are displayed.

A very intuitive and visual display and a radio control complete the maneuverability of the machine as well as the comfort for the operator to carry out his work safely and precisely.

VERSATILITY

The design of the N6870/72 allows, for everything described above, that the operation of the machine by the customer is very simple and intuitive. Each of the required parameters is controlled from the screen and when changing the thickness to be cut, the simple programming of the display indicates the position of each thread on the pulleys and drums without the possibility of error.

SECURITY

NODOSAFER machines are protected by a security closure around their entire perimeter, complying with CE security regulations.

BLOCK TROLLEY

The machine has a motorized block carrier carriage incorporated as standard.

Technical Data

Parameters |

Unit |

N6870/72 |

Max. Cutting length |

mm |

3500 |

Machine height (H) |

mm |

7650 |

Diamond wires speed |

m/s |

0-35 |

Max. Cutting height |

mm |

2200 |

Main motor power |

kw |

250 |

Minimum Cutting Thickness |

mm |

21 |

Max. Cutting width |

mm |

1960 |

Machine length (L) |

mm |

11400 |

Diamond wire length |

m |

23.50 |

Max. Number of wire |

NR |

72 |

Diamond bead diameter |

mm |

6.3 |

Flywheel Diameter |

mm |

1800 |

Machine Vertical Travel |

mm |

2400 |

Recommended Multi Wire Saw Machine Products

Jose Manuel Lopez Guitian

Jose Manuel Lopez Guitian