'TROLL' Stone Block Reinforcing Machine For Marble And Granite

FOB Price:$190000-220000

Type:

Stone Factory MachinesResin Line MachinesVacuum Resin-Treating Plants

Usage:

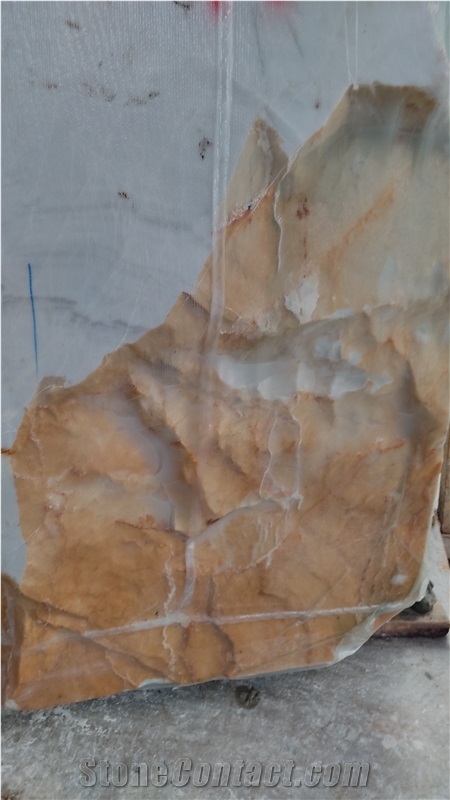

Granite, Marble, Onyx, Quartzite

After-Sale

Lead Time:

4 months

Warranty:12 Months

Install and Guarantee:Customer pay for installation

Maintenance:Online software upgrade

Machinery Function Features

The Aims of Using Block Reinforcing Line:

This system gives the reliability to transfer very fragile stone from quarries to stone factories without any loss of material. By utilizing this reinforcement process, the risk of losing defective material in the cutting process will be reduced significantly and the slabs will be guaranteed to be processed with the lowest loss of material. In the other words, using this system increase the efficiency of quarries and stone factories sharply.

The Method:

By means of pressure water, firstly the block will be washed. After that, by using a drying room, the block will be dried. Then, the block is covered into special device like; draining layer, fiber glass layer, vacuum bag and etc. to be prepared for vacuum process and resin injection. Just after the resin injection process, the block is transferred into the pressure vessel and by using a pressure cycle, a very deep penetration and a really strong cover around the block and slabs will be guaranteed. Finally, for more quick resin curing process, the block will be transferred into a drying room.

The benefits of using this innovative system:

-by means of this system, all the cracks and fissures which are connected to the surfaces of the block will be filled with resin.

-Deep resin penetration into all micro-cracks

-all of the air bubbles in the vacuum bag will be drained completely.

-really strong cover around the block and slabs

This system gives the reliability to transfer very fragile stone from quarries to stone factories without any loss of material. By utilizing this reinforcement process, the risk of losing defective material in the cutting process will be reduced significantly and the slabs will be guaranteed to be processed with the lowest loss of material. In the other words, using this system increase the efficiency of quarries and stone factories sharply.

The Method:

By means of pressure water, firstly the block will be washed. After that, by using a drying room, the block will be dried. Then, the block is covered into special device like; draining layer, fiber glass layer, vacuum bag and etc. to be prepared for vacuum process and resin injection. Just after the resin injection process, the block is transferred into the pressure vessel and by using a pressure cycle, a very deep penetration and a really strong cover around the block and slabs will be guaranteed. Finally, for more quick resin curing process, the block will be transferred into a drying room.

The benefits of using this innovative system:

-by means of this system, all the cracks and fissures which are connected to the surfaces of the block will be filled with resin.

-Deep resin penetration into all micro-cracks

-all of the air bubbles in the vacuum bag will be drained completely.

-really strong cover around the block and slabs

Technical Data

Parameters |

Unit |

Troll |

Max. Treatment slab thickness |

mm |

0 |

Max. Treatment block length |

mm |

3200 |

Sound pressure level |

dB |

- |

Max. Treatment block height |

mm |

2100 |

Machine overall height |

mm |

3650 |

Total power |

kw |

40 |

Approx. Weight |

T |

16 |

Machine overall width |

mm |

4500 |

Process efficiency |

m2/h |

- |

Power supply |

V/Hz |

400/50 |

Max. Speed of advance |

m/min |

- |

Max. Treatment block width |

mm |

2100 |

Max. Treatment slab width |

mm |

0 |

Max. Treatment slab length |

mm |

0 |

Conveyor Belt Speed |

mm/s |

0 |

Machine overall length |

mm |

5000 |

Video

Install Video

Operation Video

Screen.PrimaryScreen.Bounds.Height

Iman Pishvaei

Iman Pishvaei