JOBORN 32 Blades Super Multi Disc Bridge Saw Block Cutting Machine

FOB Price:$48000-53000

1.Taiwan famous hydraulic system.The hydraulic components from Taiwan first-line brand,react more quickly,works more stable;

2.Domestic premium brand main motor with high efficiency and more energy saving,make the cutting more powerful,and saving electricity more;

3.Germany Siemens inverter, feeding more stable; imported or domestic famous brand electrical components, with lower failure rate, help you to worry less and save more labor;

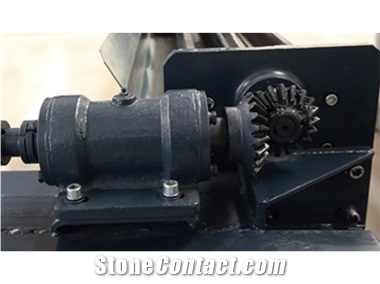

4.Side-beam rails use slide V-rail, contacting area is large, not easy to shake when cutting, ensure the plate/slabs are flatness after cutting; meanwhile,the forward and backward slicing take high precision screw-nut transmission, have automatic slicing function;

5.It uses hydraulic lifting system, combination of chrome-plated guide pin and wear guide bush, with small gap, wearable, beautiful structure, and guide sleeve with multi-layer seals, with waterproof, dust-proof, anti-spill, improving the service life;

6.Revolving working platform (Optional);

Parameters |

Unit |

SQC1800-4D Super |

SQC2200-4D Super |

SQC2600-4D Super |

SQC3000-4D Super |

Maximum block height |

mm |

750 |

950 |

1150 |

1350 |

Vertical disc diameter |

mm |

1800 |

2200 |

2600 |

3000 |

Maximum block length |

mm |

7200 |

6800 |

6400 |

6000 |

Machine length(front) |

mm |

11500 |

11500 |

11500 |

11500 |

Cooling water (1.5 bar pressure) |

L/min |

20 |

20 |

20 |

20 |

Vertical disc motor power |

kw |

110 |

110 |

110 |

110 |

Output |

m2/day(24hrs) |

500~700 |

500~700 |

500~700 |

500~700 |

Max. cutting depth |

mm |

750 |

950 |

1150 |

1350 |

Machine width |

mm |

9000 |

9000 |

9000 |

9000 |

Installed power |

kw |

128 |

128 |

128 |

128 |

Disch vertical stroke ( Z axis) |

mm |

1350 |

1350 |

1350 |

1350 |

Average level of sound power |

dB |

80 |

80 |

80 |

80 |

Bridge transversal stroke (Y axis) |

mm |

6000 |

6000 |

6000 |

6000 |

Machine height |

mm |

3700 |

3700 |

3700 |

3700 |

Cut/return stroke ( X axis) |

mm |

7200 |

6800 |

6400 |

6000 |

Approximate Weight |

Kg |

32000 |

32000 |

33000 |

33000 |

Maximum block width |

mm |

6000 |

6000 |

6000 |

6000 |

This machine adopts the PLC control system, floor type electric control cabinet, LCD touch screen (7 inches) using Chinese, English, Russian, Arabic, with the best human-computer interaction interface, the operation interface is a combination of touch screen and mechanical button to control the interface, input operating parameters through interface (including cutting size specification, moving speed) Etc., plus wireless remote control, the cutting process is automated and programmed.

SQC1800/2200/2600/3000-4D Super Block Cutting Machine(max 32 Disc) .This series machine adopts microcomputer control system and human-machine interface, uses inverter to control left-right feeding, adjusts the speed according to the stone material.

It uses hydraulic lifting system , combination of chrome-plated guide pin and wear guide bush, with small gap , wearable, beautiful structure , and guide sleeve with multi-layer seals , with waterproof , dust-proof , anti-spill , improving the service life, main motor uses brand energy-efficient motor, reduces the later using cost; forward-backward automatic slicing uses high-precision screw nut driving, main spare parts adopt imported good-quality materials; The block can be placed in the ground directly to save worktable and its maintenance costs; thus the whole machine is featured as high cutting efficiency, high slicing precision, and flatness of plate after cutting, high stability, easy-operating to suit specially cutting granite and marble block with high value and big size.

Related Products:

3YR

3YR

Frank Chow

Frank Chow