Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Easyedge V7S Vertical Edge Polisher-Breton Spa

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

Usage:

Granite, Marble, Artificial Stone

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Online software upgrade, Regular guidance & maintenance

Trade Terms

Delivery Details: FOB

Payment :

Supplier

Breton S.p.A.

Italy

Italy

Eatablished :Dec 31,1962

Main Product:

Stone Machines, Cutting Machine, Polising Machine, Wire Saw, Cnc Machines|

Contact supplier

Machinery Function Features

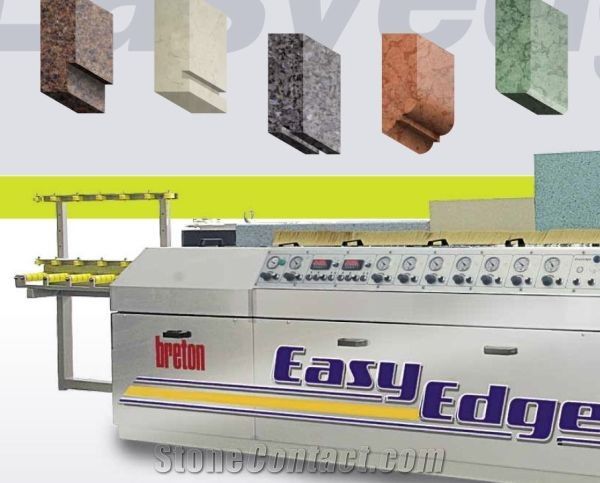

EASYEDGE V7S - VERTICAL EDGE POLISHER WITH OSCILLATING MOTION OF THE SPINDLES

Easyedge V7 is specially designed to polish straight, flat edges and to perform the upper and lower chamfers on natural and compound stone panels placed upright. The polishing spindle unit is designed with oscillating motion in order to guarantee the maximum polishing degree, independently of thickness.

At the entry, the machine is equipped with a spindle which performs the profile-shaping of the edges, or the gauging of the piece lower part, or the “drip board cut”. Because of its simple design, the Easyedge V7, which is delivere completely assembled, can be rapidly installed and started, even without the intervention of the Manufaturer’s skilled technicians. It can be floor-anchored and does not require any foundations.

The processing water is collected inside the machine and then conveyed to the point of discharge. The Easyedge V7 can polish materials up to 60 mm thick: the simple manual adjustment of the lateral presser bar according to the thickness of the piece to be worked is sufficient.

The standard machine is supplied fully equipped with:

- 1 spindle to perform the edge profile-shaping, or the thickness gauging, or the “drip board” carving.

- 7 spindles to polish the straight edge.

- 2 spindles to perform the standard chamfers.

- 1 spindle (+1 optional) to carry out deep edge bevelling.

MAIN CHARACTERISTICS

- electromechanical control of the machine without any sophisticated electronic device, in order to facilitate maintenance and make it executable to the user himself;

- polishing spindles with pneumatic pressure, equipped with multiple-labyrinth frontal radial seals and protection bellows to secure maximum reliability when working under a jet of water;

- 2 chamfering spindles with pneumatic pressure (1+1 opposed spindles) to carry out standard chamfers;

- 1 bevelling spindle with mechanical positioning (plus 1 opposed spindle) to carry out deep edge bevelling. Bevels are then polished by the pneumatic chamfering spindles;

- oscillating movement of the polishing spindle unit to guarantee the maximum polishing degree on the straight edge, independently of thickness;

- great stability of the vertical piece under working thanks to the rigidity of the seat-guided conveyor belt;

- “Plug and Play” installation and start-up of the machine, without the intervention of the Manufaturer’s skilled technicians;

- guards to keep the processing water inside the machine thus preventing it from polluting the surrounding area;

- guards and stainless steel electrical cabinet to avoid all problems of rust;

- the machine complies with CE or UL standards;

Easyedge V7 is specially designed to polish straight, flat edges and to perform the upper and lower chamfers on natural and compound stone panels placed upright. The polishing spindle unit is designed with oscillating motion in order to guarantee the maximum polishing degree, independently of thickness.

At the entry, the machine is equipped with a spindle which performs the profile-shaping of the edges, or the gauging of the piece lower part, or the “drip board cut”. Because of its simple design, the Easyedge V7, which is delivere completely assembled, can be rapidly installed and started, even without the intervention of the Manufaturer’s skilled technicians. It can be floor-anchored and does not require any foundations.

The processing water is collected inside the machine and then conveyed to the point of discharge. The Easyedge V7 can polish materials up to 60 mm thick: the simple manual adjustment of the lateral presser bar according to the thickness of the piece to be worked is sufficient.

The standard machine is supplied fully equipped with:

- 1 spindle to perform the edge profile-shaping, or the thickness gauging, or the “drip board” carving.

- 7 spindles to polish the straight edge.

- 2 spindles to perform the standard chamfers.

- 1 spindle (+1 optional) to carry out deep edge bevelling.

MAIN CHARACTERISTICS

- electromechanical control of the machine without any sophisticated electronic device, in order to facilitate maintenance and make it executable to the user himself;

- polishing spindles with pneumatic pressure, equipped with multiple-labyrinth frontal radial seals and protection bellows to secure maximum reliability when working under a jet of water;

- 2 chamfering spindles with pneumatic pressure (1+1 opposed spindles) to carry out standard chamfers;

- 1 bevelling spindle with mechanical positioning (plus 1 opposed spindle) to carry out deep edge bevelling. Bevels are then polished by the pneumatic chamfering spindles;

- oscillating movement of the polishing spindle unit to guarantee the maximum polishing degree on the straight edge, independently of thickness;

- great stability of the vertical piece under working thanks to the rigidity of the seat-guided conveyor belt;

- “Plug and Play” installation and start-up of the machine, without the intervention of the Manufaturer’s skilled technicians;

- guards to keep the processing water inside the machine thus preventing it from polluting the surrounding area;

- guards and stainless steel electrical cabinet to avoid all problems of rust;

- the machine complies with CE or UL standards;

Technical Data

Parameters |

Unit |

Easyedge V7S |

Min. workable length of the single piece |

mm |

400 |

Water consumption |

m3/h |

29 |

No. calibrating/shaping/cutting spindles |

nr |

1 |

Belt advancement speed |

mm/min |

400÷2000 |

Standard diameter of polishing wheels |

mm |

130÷150 |

Belt advancement power |

kW |

0.75 |

Number of dressing/polishing spindles |

nr |

7 |

Diameter of the drip board saw blade |

mm |

250 |

Max. processing width |

mm |

1200 |

Machine overall height |

mm |

1330 |

Calibrating/shaping/cutting spindle power |

kW |

5.5 |

Max. diameter of shaping wheel |

mm |

200 |

Machine overall width |

mm |

4300 |

Max. diameter of calibrating wheel |

mm |

180 |

Min. processing width |

mm |

50 |

Sound pressure level |

dbA |

83 |

Bevelling /Chamfering spindle power |

kW |

1.5 |

Polishing spindle rotation speed |

rpm |

1400 |

Dressing/polishing spindle power |

kW |

1.5 |

Machine overall length |

mm |

1260 |

Calibrating spindle rotation speed |

rpm |

2800 |

Standard diameter of chamfering wheels |

mm |

130 |

Max. processing thickness |

mm |

60 |

Number of Bevelling/chamfering spindles |

nr |

2+1 |

Approx. Weight |

Kg |

2200 |

Min. processing thickness |

mm |

10 |

Recommended Edge Profiling, Polishing Machine Products

Stefano Titotto

Stefano Titotto