Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

Breton Forte HD 80 4-Axes CNC Machining Center

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

Usage:

Granite, Marble, Artificial Stone

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Online software upgrade, Regular guidance & maintenance

Trade Terms

Delivery Details: FOB

Payment :

Supplier

Breton S.p.A.

Italy

Italy

Eatablished :Dec 31,1962

Main Product:

Stone Machines, Cutting Machine, Polising Machine, Wire Saw, Cnc Machines|

Contact supplier

Machinery Function Features

FORTE HD 80

WITH A PRESTIGIOUS PAST

The new Forte HD 80 comes from the experience of the previous Contourbreton models, countless examples of which have been sold worldwide with great success.

WIDE TRAVELS, SAFETY & ACCESSIBILITY

WIDE TRAVELS, SAFETY & ACCESSIBILITY

Wide working travel of 3,200/3,800 mm in “X” axis,

COMPACT 1.950/ WIDE 2.300/ EXTREME 4.000 mm in “Y” and 300 mm in “Z” (vertical axis).

The Forte HD 80’s comes with manually opening doors with safety interlock switches.

The work table is made from a single piece of a special quartz-based polymeric material, Metalquartz®.

Large doors and lower work table with integrated step offer the best front access ergonomics in the industry.

DESIGNED TO PERFORM

The strong electro-welded structure ensures the rigidity needed for any kind of machining.

DRIVEN BY SIEMENS BRUSHLESS MOTORS

Racks & pinions systems and Siemens brushless motors drive the mobile bridge and the spindle unit.

A gantry system drives the mobile bridge. Linear guides with recirculating balls and precision encoders assure the movement accuracy.

WORK TABLE IN METALQUARTZ ®

Continuous work table made of Metalquartz®, a special patented quartz-based composite material with a polymeric matrix, specially engineered to ensure the same high rigidity and expansion coefficient as steel.

HIGH PERFORMANCE VACUUMING SYSTEM

Liquid ring vacuum pump with high performance and low maintenance costs.

EXCELS IN THE DETAILS

• Tool cooling with internal and external water supply.

• Spindle vertical travel of 300 mm, with distance of 520 mm from spindle nose to work table, performing slotting on small blocks.

• The spindle is mounted on a rigid cast iron structure, minimizing flexions under any working conditions.

• Digital motors.

• Vacuum system with frontal controls, conveniently located for the operator.

• Axes “rapid” movements of up to 80 meters per minute

• In-line tool store located on both internal sides of the machine.

• HSK-B80 standard tool mounting shank.

• 4th C-axis (optional).

POWERFUL BRETON SPINDLE, DESIGNED EXCLUSIVELY FOR WORKING NATURAL STONE, ENGINEERED STONE AND STONEWARE

Powerful spindle manufactured by Breton, with closed circuit liquid cooling, three ceramic bearings with large diameter, featuring high-performance (30 Nm with 14.500 rpm), specially designed and built for working natural stone, engineered stone and stoneware.

USER-FRIENDLY CNC CONTROL UNIT

Forte HD 80 incorporates the ultimate generation of the Siemens Sinumerik 840D SL computer numerical control (CNC), a digital control compatible with PC architecture, and a PC based on Windows 7 operating system. The control panel is swiveling, provided with keypad and color-touchscreen with USB port. A portable button panel duplicates the main machine controls (axes management + handwheel, emergency stop, etc.) consenting the operator to carry out and closely monitor all those delicate operations directly on the workpiece to be machined.

BRETON SMART CAM COUNTERTOPS: the cad/cam software for the production of countertops on countoring centers

The CAM module allows to carry out the following major functions:

• cutting with saw blade

• contouring, profiling, drilling, milling and pocketing with milling or profiling tools

• honing of surfaces, even inclined

• milling and polishing of grooves, even on inclined surfaces

• 3D engraving of Windows “True Type” fonts on flat horizontal or vertical surfaces

• automatic generation of toolpaths based on a pre-defined technological table

• fast editing of Lead In/Out toolpaths

The CAD module also allows:

• creation of two-dimensional drawings with relative dimensioning

• import of drawings in DXF and DWG format from different CAD program or templating systems

• automatic programming and display of the vacuum pods arrangement on the work table

• interface with the software of a possible laser projector for arranging the vacuum pods on the work table

The 3D SOLID SIMULATION module allows:

• to check any possible tool-piece and/or tool-machine collision. The software operates in a Windows environment, is intuitive and user-friendly.

NOTE: The software features may be limited by the technological and operational features of the machine.

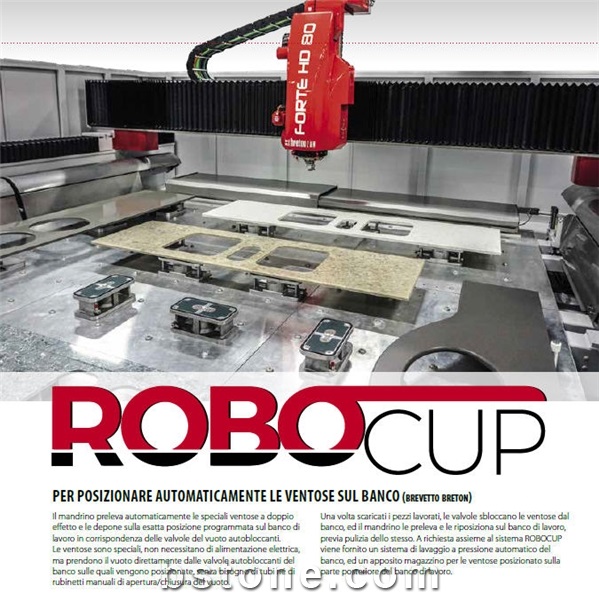

A ROBOT FOR ROBOCUP

It is now possible to further improve performance and cycle times for the Forte HD 80 Robocup by equipping it with a workpiece manipulation anthropomorphic robot with vacuum end-of-arm tooling.

The robotized application was created by Breton with Optidrive, a company specialized in Kuka anthropomorphic robot software and integration.

This robotized application allows to automatically position even large workpieces (up to 3.400x1.600m) on the pods, taking them from the feeding roller conveyor in a mere 34 seconds.

When the job is finished, the robot places the machined slab on the unloading roller conveyor, while discharging chips and automatically washing the work table.

FOR THE AUTOMATIC POSITIONING OF THE VACUUM CUPS ON THE TABLE (breton patent)

WITH A PRESTIGIOUS PAST

The new Forte HD 80 comes from the experience of the previous Contourbreton models, countless examples of which have been sold worldwide with great success.

WIDE TRAVELS, SAFETY & ACCESSIBILITY

WIDE TRAVELS, SAFETY & ACCESSIBILITY

Wide working travel of 3,200/3,800 mm in “X” axis,

COMPACT 1.950/ WIDE 2.300/ EXTREME 4.000 mm in “Y” and 300 mm in “Z” (vertical axis).

The Forte HD 80’s comes with manually opening doors with safety interlock switches.

The work table is made from a single piece of a special quartz-based polymeric material, Metalquartz®.

Large doors and lower work table with integrated step offer the best front access ergonomics in the industry.

DESIGNED TO PERFORM

The strong electro-welded structure ensures the rigidity needed for any kind of machining.

DRIVEN BY SIEMENS BRUSHLESS MOTORS

Racks & pinions systems and Siemens brushless motors drive the mobile bridge and the spindle unit.

A gantry system drives the mobile bridge. Linear guides with recirculating balls and precision encoders assure the movement accuracy.

WORK TABLE IN METALQUARTZ ®

Continuous work table made of Metalquartz®, a special patented quartz-based composite material with a polymeric matrix, specially engineered to ensure the same high rigidity and expansion coefficient as steel.

HIGH PERFORMANCE VACUUMING SYSTEM

Liquid ring vacuum pump with high performance and low maintenance costs.

EXCELS IN THE DETAILS

• Tool cooling with internal and external water supply.

• Spindle vertical travel of 300 mm, with distance of 520 mm from spindle nose to work table, performing slotting on small blocks.

• The spindle is mounted on a rigid cast iron structure, minimizing flexions under any working conditions.

• Digital motors.

• Vacuum system with frontal controls, conveniently located for the operator.

• Axes “rapid” movements of up to 80 meters per minute

• In-line tool store located on both internal sides of the machine.

• HSK-B80 standard tool mounting shank.

• 4th C-axis (optional).

POWERFUL BRETON SPINDLE, DESIGNED EXCLUSIVELY FOR WORKING NATURAL STONE, ENGINEERED STONE AND STONEWARE

Powerful spindle manufactured by Breton, with closed circuit liquid cooling, three ceramic bearings with large diameter, featuring high-performance (30 Nm with 14.500 rpm), specially designed and built for working natural stone, engineered stone and stoneware.

USER-FRIENDLY CNC CONTROL UNIT

Forte HD 80 incorporates the ultimate generation of the Siemens Sinumerik 840D SL computer numerical control (CNC), a digital control compatible with PC architecture, and a PC based on Windows 7 operating system. The control panel is swiveling, provided with keypad and color-touchscreen with USB port. A portable button panel duplicates the main machine controls (axes management + handwheel, emergency stop, etc.) consenting the operator to carry out and closely monitor all those delicate operations directly on the workpiece to be machined.

BRETON SMART CAM COUNTERTOPS: the cad/cam software for the production of countertops on countoring centers

The CAM module allows to carry out the following major functions:

• cutting with saw blade

• contouring, profiling, drilling, milling and pocketing with milling or profiling tools

• honing of surfaces, even inclined

• milling and polishing of grooves, even on inclined surfaces

• 3D engraving of Windows “True Type” fonts on flat horizontal or vertical surfaces

• automatic generation of toolpaths based on a pre-defined technological table

• fast editing of Lead In/Out toolpaths

The CAD module also allows:

• creation of two-dimensional drawings with relative dimensioning

• import of drawings in DXF and DWG format from different CAD program or templating systems

• automatic programming and display of the vacuum pods arrangement on the work table

• interface with the software of a possible laser projector for arranging the vacuum pods on the work table

The 3D SOLID SIMULATION module allows:

• to check any possible tool-piece and/or tool-machine collision. The software operates in a Windows environment, is intuitive and user-friendly.

NOTE: The software features may be limited by the technological and operational features of the machine.

A ROBOT FOR ROBOCUP

It is now possible to further improve performance and cycle times for the Forte HD 80 Robocup by equipping it with a workpiece manipulation anthropomorphic robot with vacuum end-of-arm tooling.

The robotized application was created by Breton with Optidrive, a company specialized in Kuka anthropomorphic robot software and integration.

This robotized application allows to automatically position even large workpieces (up to 3.400x1.600m) on the pods, taking them from the feeding roller conveyor in a mere 34 seconds.

When the job is finished, the robot places the machined slab on the unloading roller conveyor, while discharging chips and automatically washing the work table.

FOR THE AUTOMATIC POSITIONING OF THE VACUUM CUPS ON THE TABLE (breton patent)

Technical Data

Parameters |

Unit |

FORTE HD 80 COMPACT |

FORTE HD 80 WIDE |

FORTE HD 80 EXTREME |

Approx. Weight |

Kg |

7500 |

8000 |

10000 |

X axis stroke |

mm |

3200 |

3800 |

3800 |

Tool max. length |

mm |

240 |

240 |

240 |

Machine overall height |

mm |

2250 |

2250 |

2250 |

Z axis rapid speed |

m/min |

0÷30 |

0÷30 |

0÷30 |

Y axis stroke |

mm |

1950 |

2300 |

4000 |

X axis rapid speed |

m/min |

0÷80 |

0÷80 |

0÷80 |

Max. working thickness |

mm |

10 |

10 |

10 |

Water requirement |

l/min |

5.3/10.6 |

5.3/10.6 |

5.3/10.6 |

Tool-holder spindle rotation speed |

rpm |

0÷14.500 |

0÷14.500 |

0÷14.500 |

Machine overall width |

mm |

3250 |

3950 |

5500 |

Linear tool-store capacity |

nr |

12+12 tools |

17+17 tools |

31+31 tools |

Z axis stroke |

mm |

300 |

300 |

300 |

Sound pressure level |

dbA |

75 |

75 |

75 |

Tool max. diameter |

mm |

140 |

140 |

140 |

Max. working length |

mm |

3200 |

3740 |

4000 |

Number of axes |

nr |

4 |

4 |

4 |

Tool cooling |

int./ext. |

int./ext. |

int./ext. |

|

Min. working thickness |

mm |

40 |

40 |

40 |

Machine overall length |

mm |

6000 |

6700 |

6700 |

Y axis rapid speed |

m/min |

0÷60 |

0÷60 |

0÷60 |

Dimensions of the work table (length x width) |

mm |

3200x1900 |

3740x2240 |

4000x3740 |

Tool-holder spindle motor power |

kW |

16 |

16 |

16 |

Max. working width |

mm |

1900 |

2240 |

3740 |

Work table height |

mm |

830-900 |

830-900 |

830-900 |

Software

BRETON SMART CAM COUNTERTOPS: the cad/cam software for the production of countertops on countoring centersThe CAM module allows to carry out the following major functions:

• cutting with saw blade

• contouring, profiling, drilling, milling and pocketing with milling or profiling tools

• honing of surfaces, even inclined

• milling and polishing of grooves, even on inclined surfaces

• 3D engraving of Windows “True Type” fonts on flat horizontal or vertical surfaces

• automatic generation of toolpaths based on a pre-defined technological table

• fast editing of Lead In/Out toolpaths

The CAD module also allows:

• creation of two-dimensional drawings with relative dimensioning

• import of drawings in DXF and DWG format from different CAD program or templating systems

• automatic programming and display of the vacuum pods arrangement on the work table

• interface with the software of a possible laser projector for arranging the vacuum pods on the work table

The 3D SOLID SIMULATION module allows:

• to check any possible tool-piece and/or tool-machine collision. The software operates in a Windows environment, is intuitive and user-friendly.

NOTE: The software features may be limited by the technological and operational features of the machine.

A ROBOT FOR ROBOCUP

It is now possible to further improve performance and cycle times for the Forte HD 80 Robocup by equipping it with a workpiece manipulation anthropomorphic robot with vacuum end-of-arm tooling.

The robotized application was created by Breton with Optidrive, a company specialized in Kuka anthropomorphic robot software and integration.

This robotized application allows to automatically position even large workpieces (up to 3.400x1.600m) on the pods, taking them from the feeding roller conveyor in a mere 34 seconds.

When the job is finished, the robot places the machined slab on the unloading roller conveyor, while discharging chips and automatically washing the work table.

FOR THE AUTOMATIC POSITIONING OF THE VACUUM CUPS ON THE TABLE (breton patent)

Processed Stone Photos

Components

Recommended CNC Working Center Products

Stefano Titotto

Stefano Titotto