Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesStone Waxing Machine

Pedrini M242 Automatic Slabs Waxing Machine

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesStone Waxing Machine

Usage:

Marble, Limestone, Onyx, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation

Maintenance:Remote troubleshooting, Field troubleshooting

Machinery Function Features

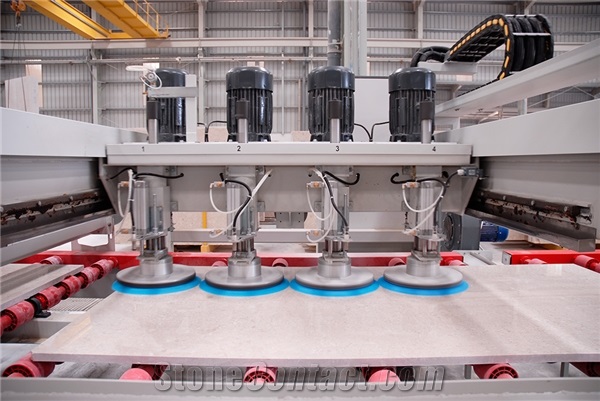

Automatic machine for the waxing operation on marble, granite and similar stones slabs. A robust frame supports the movable beam and the wax distributor. Beam stroke, that adjusts automatically in relationship to slabs width, is driven through two pinion- rack synchronized systems with inverter adjusted speed. The spindles, equipped with rotating brushes are assembled onto movable beam.

Automatic machine for the application of protecting products on the surface of marble, granite and similar stones slabs and strips.

The products, such as waxes or protecting liquids, are dosed and directly applied on the material surface, uniformly distributed by means of a series of rotating brushes.

The waxing machine is normally included in a continuous cycle automatic line placed after the material polishing and drying.

The waxing machine M242 is manufactured in the following configurations:

• With 4 or 6 spindles to process slabs up to 2200 mm width;

• With 3 spindles to process strips up to 650 mm width.

The waxing machine M242 is composed of a sturdy bridge structure which supports the mobile beam housing the spindles which drive the rotating brushes.

The bridge structure allows to install the machine on a motorized roller bench, already existing or to be separately supplied as well.

All parts have undergone structural checks following the FEM (Finite Element Method) and their precision ensures perfect machine geometry and correct assembly on site.

The machine surface is protected with a three-layer paint cycle applied after the sandblasting operation.

A suitable fiberglass door, which can be opened upwards,allows the machine access for maintenance and, at the same time, it acts as a locking and safety system to prevent accidental opening.

The beam translation movement is driven by two pinion/rack synchronized systems with inverter-controlled speed and is automatically adjusted according to the slabs width.

The spindles, with automatic up and down movement and pneumatic driving, are equipped with interchangeable rotating brushes and mounted onto the mobile beam.

The product distribution on the surface is performed through a pump fixed on the machine structure which, by means of a proper pipe, directly draws from the product container.

The general electric panel is mounted on the rear machine structure and is protected against dust and water in compliance with IP 54 standard (EN 60529).

The main control panel is placed on the front of the machine and includes a touch-screen PLC for the automatism management.

Each single spindle is equipped with an auxiliary control panel with exclusion switch and working pneumatic pression adjustment.

The waxing machine M242 is manufactured in the version for the processing of strips or of elements up to 650 mm width as well. The material transport is performed through a motorized belt equipped with adjustable guides to keep the material in the centre

Automatic machine for the application of protecting products on the surface of marble, granite and similar stones slabs and strips.

The products, such as waxes or protecting liquids, are dosed and directly applied on the material surface, uniformly distributed by means of a series of rotating brushes.

The waxing machine is normally included in a continuous cycle automatic line placed after the material polishing and drying.

The waxing machine M242 is manufactured in the following configurations:

• With 4 or 6 spindles to process slabs up to 2200 mm width;

• With 3 spindles to process strips up to 650 mm width.

The waxing machine M242 is composed of a sturdy bridge structure which supports the mobile beam housing the spindles which drive the rotating brushes.

The bridge structure allows to install the machine on a motorized roller bench, already existing or to be separately supplied as well.

All parts have undergone structural checks following the FEM (Finite Element Method) and their precision ensures perfect machine geometry and correct assembly on site.

The machine surface is protected with a three-layer paint cycle applied after the sandblasting operation.

A suitable fiberglass door, which can be opened upwards,allows the machine access for maintenance and, at the same time, it acts as a locking and safety system to prevent accidental opening.

The beam translation movement is driven by two pinion/rack synchronized systems with inverter-controlled speed and is automatically adjusted according to the slabs width.

The spindles, with automatic up and down movement and pneumatic driving, are equipped with interchangeable rotating brushes and mounted onto the mobile beam.

The product distribution on the surface is performed through a pump fixed on the machine structure which, by means of a proper pipe, directly draws from the product container.

The general electric panel is mounted on the rear machine structure and is protected against dust and water in compliance with IP 54 standard (EN 60529).

The main control panel is placed on the front of the machine and includes a touch-screen PLC for the automatism management.

Each single spindle is equipped with an auxiliary control panel with exclusion switch and working pneumatic pression adjustment.

The waxing machine M242 is manufactured in the version for the processing of strips or of elements up to 650 mm width as well. The material transport is performed through a motorized belt equipped with adjustable guides to keep the material in the centre

Technical Data

Parameters |

Unit |

M242LD-4 |

M242LD-6 |

M242LS-3 |

Max. working width |

mm |

2200 |

2200 |

650 |

Conveyor system control motor |

kw |

Not included |

Not included |

1,1 |

Max. working thickness |

mm |

100 |

100 |

80 |

Brush equipped spindles quantity |

nr |

4 |

6 |

3 |

Machine overall width |

mm |

3100 |

3100 |

1700 |

Machine overall height |

mm |

2200 |

2200 |

2200 |

Air consumption |

L/min |

80 |

120 |

70 |

Beam motor power |

kw |

1,5 |

1,5 |

1,5 |

Machine overall length |

mm |

2200 |

3200 |

3000 |

Power of each spindle |

kw |

4 kW 50 Hz/5,5 kW 60 Hz |

4 kW 50 Hz /5,5 kW 60 Hz |

4 kW 50 Hz /5,5 kW 60 Hz |

Approx. Weight |

Kg |

2200 |

2600 |

2000 |

Giambattista Pedrini

Giambattista Pedrini