Quartz slab press machine automatic press line, Artificial Stone Machine

FOB Price:$500000-1100000

Type:

Artificial Stone MachinesPressing Machine

Usage:

Artificial Stone

After-Sale

Lead Time:

90 DAYS

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting

Machinery Function Features

Eaststar Artificial Quartz Stone Production Line

The artificial quartz stone production line is mainly composed of hopper, conveyor, batching system, mixing system, crusher machine, material distribution machine, press machine, solidifying oven, test machine, etc. The test machine is the prototype of the core parts of the whole plant, with which the recipe can be tested by forming artificial quartz stone slab samples, volume production will only be made after successful tests.

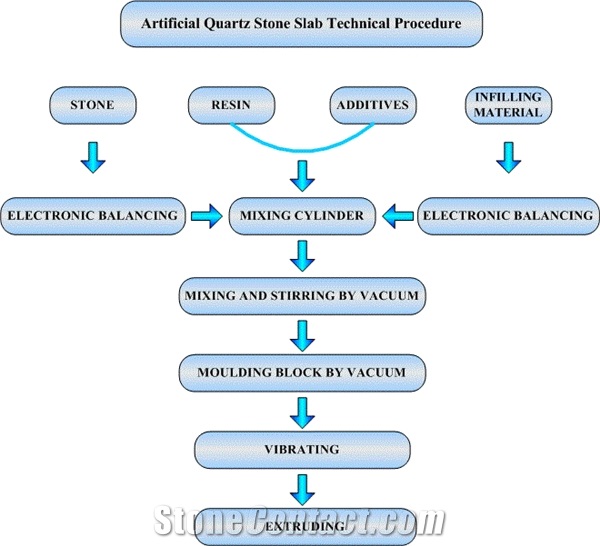

The process of the entire line is, weight the raw materials (quartz powder, sand, etc) by the → send them to the mixer by the conveyor → add to auxiliary material (resin, firming agent, coupling agent, etc), mix individually and mix all-together → distribute material in the distribution machine → put the mixed material into press machine → vacuum vibration pressing and shaping → solidify in solidifying oven → cooling → quartz slab

Process formula and raw materials consumption(unit:kg)

mixer powder

Mixed Resin

Initiator

weigh

178

85.44

21.36

0.2136

Comparing with similar competitors' artificial quartz stone production machine, Eaststar machine with the following advantages:

,Eaststar:

(1).High production capacity : 1 rough slab per 4~5 min with 3.25*1.65m, (Thickness: 12~50mm ).Count as work time at 20 hours per one day and 300 days per one year , the yearly output will above 380000.

:3.25*1.65,4~5,20,25,38

(2). Quartz produced by our production line with high density and hardness: Density is 2.35-2.45g/cm3; Mohs' hardness is 6-7.

,:2.35-2.45g/cm3; 6-7

(3).High automation : Whole processing are controlled by computer, stable quality, manpower-saving, high product qualified rate, the mixer with the latest technology in the world, thorough-paced mixing and full-automation material feeding render certain the high & stable quality product.

(4).Abolition of the mold, saving costs, higher productivity and lessening the chance of deforming slab.

(5).New improvement of solidifying oven, using no-deforming steel slab, ensure planar slab; heated evenly; saving energy.

(6).Advanced shaping & solidifying technology: Resin using percentage is about 6%-9% only, largest saving production cost and ensuring the high-quality product.

:6-9%,,

(7).Stabilized and reliable of our machine, lowest failure rate and maintenance cost.

(8).Providing completed and dedicated technical support. Redesign equipments according to customer's practical demands. For example, design the solidifying oven heating using natural gas replaces electric power.

Raw material and formula

SiO2 powder ( please see our stone powder grinding mill machine)

Natural quartz scrap;

Powder;

Resin;

Initiator;

Firming agent, etc.

Specification ( ,,: Full Automatic and semi automatic. )

Artificial quartz slab size :

3250*1650mm; 3250*1250mm;

2450*1850mm; 2450*1650mm.

Total powder: Max.850KW, Avg.600KW;

Capacity: 4-5 Minutes produce 1 piece quartz slab

Land Area Requirement

Raw material warehouse:2000 .

Artificial quartz production line workshop: 2000

Warehouse: 2000

The artificial quartz stone production line is mainly composed of hopper, conveyor, batching system, mixing system, crusher machine, material distribution machine, press machine, solidifying oven, test machine, etc. The test machine is the prototype of the core parts of the whole plant, with which the recipe can be tested by forming artificial quartz stone slab samples, volume production will only be made after successful tests.

The process of the entire line is, weight the raw materials (quartz powder, sand, etc) by the → send them to the mixer by the conveyor → add to auxiliary material (resin, firming agent, coupling agent, etc), mix individually and mix all-together → distribute material in the distribution machine → put the mixed material into press machine → vacuum vibration pressing and shaping → solidify in solidifying oven → cooling → quartz slab

Process formula and raw materials consumption(unit:kg)

mixer powder

Mixed Resin

Initiator

weigh

178

85.44

21.36

0.2136

Comparing with similar competitors' artificial quartz stone production machine, Eaststar machine with the following advantages:

,Eaststar:

(1).High production capacity : 1 rough slab per 4~5 min with 3.25*1.65m, (Thickness: 12~50mm ).Count as work time at 20 hours per one day and 300 days per one year , the yearly output will above 380000.

:3.25*1.65,4~5,20,25,38

(2). Quartz produced by our production line with high density and hardness: Density is 2.35-2.45g/cm3; Mohs' hardness is 6-7.

,:2.35-2.45g/cm3; 6-7

(3).High automation : Whole processing are controlled by computer, stable quality, manpower-saving, high product qualified rate, the mixer with the latest technology in the world, thorough-paced mixing and full-automation material feeding render certain the high & stable quality product.

(4).Abolition of the mold, saving costs, higher productivity and lessening the chance of deforming slab.

(5).New improvement of solidifying oven, using no-deforming steel slab, ensure planar slab; heated evenly; saving energy.

(6).Advanced shaping & solidifying technology: Resin using percentage is about 6%-9% only, largest saving production cost and ensuring the high-quality product.

:6-9%,,

(7).Stabilized and reliable of our machine, lowest failure rate and maintenance cost.

(8).Providing completed and dedicated technical support. Redesign equipments according to customer's practical demands. For example, design the solidifying oven heating using natural gas replaces electric power.

Raw material and formula

SiO2 powder ( please see our stone powder grinding mill machine)

Natural quartz scrap;

Powder;

Resin;

Initiator;

Firming agent, etc.

Specification ( ,,: Full Automatic and semi automatic. )

Artificial quartz slab size :

3250*1650mm; 3250*1250mm;

2450*1850mm; 2450*1650mm.

Total powder: Max.850KW, Avg.600KW;

Capacity: 4-5 Minutes produce 1 piece quartz slab

Land Area Requirement

Raw material warehouse:2000 .

Artificial quartz production line workshop: 2000

Warehouse: 2000

Technical Data

Parameters |

Unit |

ES3250 |

Vibration in minute |

pcs |

1 |

Compressed air |

NL/min |

10000 |

Machine overall length |

mm |

100000 |

Approx. Weight |

Kg |

10000 |

Total power |

kw |

450 |

Minimum air pressure |

bar |

1000 |

Max. slab thickness |

mm |

60 |

Max. loading |

Kg |

200 |

Max. Production |

m2/h |

3250 |

Min. slab thickness |

mm |

15 |

Vibration motor power |

kw |

450 |

Machine overall height |

mm |

8500 |

Pressing cycle |

minute/piece |

4 |

Sound pressure level |

dB |

25 |

Max. slab length |

mm |

3250 |

Pressure |

T |

10000 |

Max. slab width |

mm |

1650 |

Production capacity |

piece/hour |

20 |

Machine overall width |

mm |

20000 |

Work Example

The process of the entire line is, weight the raw materials (quartz powder, sand, etc) by the → send them to the mixer by the conveyor → add to auxiliary material (resin, firming agent, coupling agent, etc), mix individually and mix all-together → distribute material in the distribution machine → put the mixed material into press machine → vacuum vibration pressing and shaping → solidify in solidifying oven → cooling → quartz slab

Video

Install Video

Operation Video

Screen.PrimaryScreen.Bounds.Height

Recommended Pressing Machine Products

Chantal Z

Chantal Z