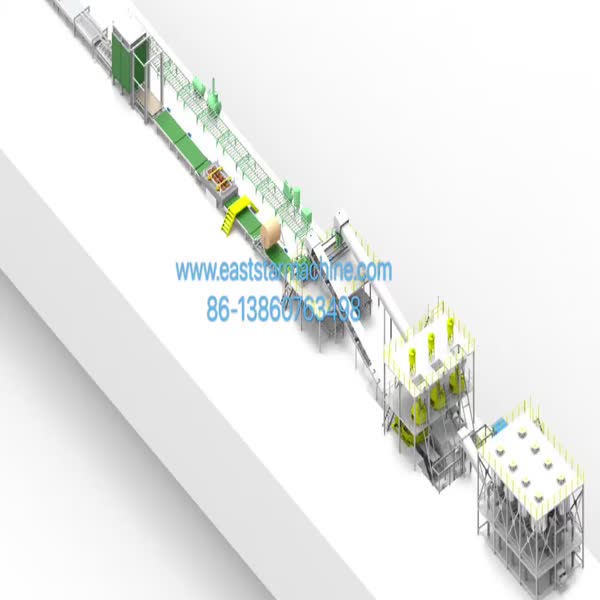

Quartz slab making machine , Quartz slab production line

FOB Price:$600000-1100000

The process of the entire line is, weight raw materials (quartz powder, sand, etc) by hopper → send them to the mixer by conveyor → add auxiliary material (resin, firming agent, coupling agent, etc), mono-color mixing and then mixing all together → distribute mixed material in the distribution machine → and then put it into press machine → vibrate and press in vacuum for shaping → solidify in solidifying oven → cooling → rough slab→cross cutting→ width cutting→ calibrating for A side→ turning slab over→ calibrating for B side→further polishing line→final slab.

Parameters |

Unit |

ES3250 |

Max. Production |

m2/h |

200 |

Machine overall width |

mm |

20000 |

Max. slab thickness |

mm |

60 |

Minimum air pressure |

bar |

100000 |

Compressed air |

NL/min |

100000 |

Vibration in minute |

nr |

5 |

Sound pressure level |

dB |

25 |

Machine overall length |

mm |

200000 |

Production capacity |

piece/hour |

1.5 |

Pressing cycle |

minute/piece |

40 |

Pressure |

T |

100 |

Min. slab thickness |

mm |

20 |

Max. slab length |

mm |

3250 |

Machine overall height |

mm |

1200 |

Max. loading |

Kg |

10000 |

Max. slab width |

mm |

2450 |

Approx. Weight |

Kg |

10000 |

Total power |

kw |

1100 |

Vibration motor power |

kw |

700 |

Eaststar quartz slab stone production line is mainly composed of hopper, conveyor, batching system, mixing system, crusher machine, material distribution machine, press machine, solidifying oven, test machine, etc. The test machine is the prototype of the core parts of the whole plant, with which the recipe can be tested by forming artificial quartz stone slab samples, volume production will only be made after successful tests.

The process of the entire line is, weight raw materials (quartz powder, sand, etc) by hopper → send them to the mixer by conveyor → add auxiliary material (resin, firming agent, coupling agent, etc), mono-color mixing and then mixing all together → distribute mixed material in the distribution machine → and then put it into press machine → vibrate and press in vacuum for shaping → solidify in solidifying oven → cooling → rough slab→cross cutting→ width cutting→ calibrating for A side→ turning slab over→ calibrating for B side→further polishing line→final slab.

Resin |

|

|

| Quartz stone |

|

|

| 325 mesh quartz power |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Weigh |

|

|

|

|

|

|

|

| ↓ |

|

|

Firming agent | → | Weigh & uniformly mixing | → | Mix uniformly in mixer | → | Distribution in distribution machine | ||

|

|

|

|

|

| ↑ |

| ↓ |

|

|

|

|

|

| Weigh |

| Vacuum vibration pressing & shaping |

Coupling agent |

|

|

|

|

| ↑ |

| ↓ |

|

|

|

|

|

| Pigment |

| Solidify in solidifying oven |

|

|

|

|

|

|

|

| ↓ |

|

|

|

|

|

|

|

| Cooling slab |

|

|

|

|

|

|

|

| ↓ |

Warehouse | ← | Finish slab | ← | Calibrating & polishing | ← | Rough slab | ||

2.Artificial quartz production line raw materials and formula introduction

(1) Raw material

Natural quartz scrap;

Powder;

Resin;

Initiator;

Firming agent, etc.

(2)Technology Formula and Raw Material Consumption

There can be many types of Artificial quartz stone slab. Different design comes from different technical formula. Take slab size: 3250×1650×18mm as the example, the fomulation and process should subjects to the following sheet (1 piece).

Raw Material consumption ( unit: kg )

Raw material | Stone sand | Powder | Resin | Firming agent |

Weight | 165 | 70.8 | 16.52 | 0.165 |

3.Yearly raw material cost (depend on output)

1.Quartz sand :8476 ton

2.Quartz powder: 4069 ton

- Resin : 1017 ton

- Chemicals and color: 10 ton

4.Quartz slab production raw material standard

A.Raw material list and ratio:

Material | Standard | Ratio | Remark |

Quartz sand | 10-20 mesh 、 20-40 mesh、26-40 mesh、40-70 mesh、70-140 mesh. | 60-63% |

|

Quartz powder | (325 mesh、400 mesh、800 mesh、1250 mesh | 60-63% |

|

intersperse material | jade scrap,mirror,glass, sea shell, colorful stone scrap,etc | Depend on formula |

|

resin |

| 6-7% |

|

Coupling agent |

| 0.4-0.6% |

|

Decomposing agent |

| 0.5-1% |

|

Curing agent |

| 0.8-1% |

|

B.Material quality requirements:

- Appearance

Uniform colors: no miscellaneous colors and sundries.Mottled particles are generally required to be below 2%. Good surface cleanliness: no dust, particle surface clean.

2.Shape

Granule is required, the granule is more spherical.The smaller the specific surface area.The smaller the specific surface area, the smaller the oil absorption value, the less resin used.Non - granular quartz sand increases the resistance when mixing.

- Sand and powder size:

From 4-6#、6-8#、8-16#、16-26#、26-40#、40-70#、70-120#、325-400#、800-2500#,etc.

4.Whiteness

Quartz material≥ 90 .( The material does not blacken with mixed with resin if the whiteness over than 90.)

- Other index

Wet ≤ 0.5% 。

acid fastness ≥99%

Oil absorption ≤ 19%-24%

SiO2 fineness (China market ) 90-94%

5.Manufacturing cost for 1 sq meter slab

1).Productivity:

Slab size : 3250×1650×(15~40)mm.

**1 slab / 4~5 min

**1287㎡/day (Work time: 20 hours)

**32175㎡/month (Work day: 25 day)

**386000㎡/year (Count as the work time with 20 hours per day and 300 days per year).

Eaststar quartz slab press machine and full automatic quartz slab production line

(1) . Highproduction capacity : 4~5 min/ slab (25*1.65m),Thickness of finished slab: 12~30mm.

(2). High density and hardness of our slab: Density: 2.35-2.45g/cm3; Mohs' hardness: 6-7.

(3).Full automation: The entire production process can be fully controlled by computer, stable quality production, manpower-saving, high production rate, we got a relative top technology at the international level about the mixer, thorough-paced mixing and full-automation material feeding to ensure the good quality quartz slab.

(4). Adoption of new type mold: We apply new type mold instead of traditonal framework for shaping rough slab, which helps reduce deforming slab during the production process.

(5).Upgrade technology of solidifying oven: 1.We apply non-deforming steel plate to heat rough slab,so that ensure quartz slab heated more evenly and more energy saved. 2.Traditional solidifying oven can only heat 14 pieces at the same time, but our latest technology allows 24 pieces.

(6).Advanced shaping & solidifying technology: The percentage of resin usage is about 6%-9% only, which saves production cost and ensures the high-quality quartz slab.

(7).Stable and reliable operation of our machine: It has the features of low failure rate and helps to save maintenance cost.

(8).Providing comprehensive technical support. Redesign equipment according to customer’s practical demands. For example, design the solidifying oven heating using natural gas replaces electric power.

Chantal Z

Chantal Z