Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesStone Drilling, Slot Machine

MINI HORIZONTAL DRILLING MACHINE

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesStone Drilling, Slot Machine

Usage:

Granite, Marble, Limestone, Onyx, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Remote troubleshooting

Machinery Function Features

EQUIPPED WITH:

2 drilling units

1 milling machine for the pocket

The machine is made up of a solid base in metalwork fabrication upon which two traverse chrome-plated bars are mounted. Two carts for slabs handling travel along the bars: each cart features two rows of idle wheels.

Cart motion adapts to the different sizes of the slabs thanks to a cross-head nut operated by means of a small manual wheel. The supports of the carts move along self-lubricating bushes.

The slab is hold in position by two steel guides along each of the two rows of idle wheels.

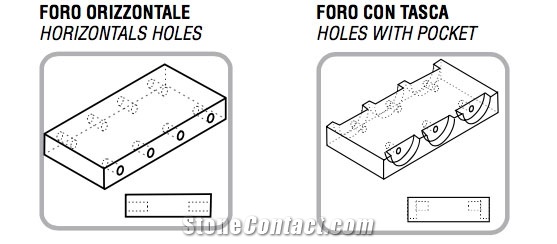

The two drilling units are placed alongside each cart. They are pneumatically operated by a hydraulic brake and are used to make holes on the slab edge.

MACHINE SPECIFICATIONS:

Slab max width 120 cm

Slab min width 20 cm

Penetration speed can be adjusted as follows:

to slowly penetrate into the slab until the diamond pointisguided(about3 ÷4mm);

to penetrate, at a higher speed, into the remaining 90% of the hole in order to complete it as fast as possible.

Once the hole has been completed, the return speed is always high.

Hole depth is varied by adjusting a magnetic sensor.

Hole positions are obtained by placing two retraction mechanical locks on one of the two carts. A milling machine is placed above one of the two drilling units in order to create the pocket. The milling machine is pneumatically operated by means of a brake and its speed can be adjusted to:

quickly reach the slab

perform final cutting.

Return speed is always at the maximum value.

The stroke corresponding to the two speeds can be adjusted by using microswitches. Cutting is aligned with the hole.

Once the slab is positioned, pocket drilling and cutting are automatic. The operator must press the corresponding button to start cutting. Either spindle can be excluded from drilling.

2 drilling units

1 milling machine for the pocket

The machine is made up of a solid base in metalwork fabrication upon which two traverse chrome-plated bars are mounted. Two carts for slabs handling travel along the bars: each cart features two rows of idle wheels.

Cart motion adapts to the different sizes of the slabs thanks to a cross-head nut operated by means of a small manual wheel. The supports of the carts move along self-lubricating bushes.

The slab is hold in position by two steel guides along each of the two rows of idle wheels.

The two drilling units are placed alongside each cart. They are pneumatically operated by a hydraulic brake and are used to make holes on the slab edge.

MACHINE SPECIFICATIONS:

Slab max width 120 cm

Slab min width 20 cm

Penetration speed can be adjusted as follows:

to slowly penetrate into the slab until the diamond pointisguided(about3 ÷4mm);

to penetrate, at a higher speed, into the remaining 90% of the hole in order to complete it as fast as possible.

Once the hole has been completed, the return speed is always high.

Hole depth is varied by adjusting a magnetic sensor.

Hole positions are obtained by placing two retraction mechanical locks on one of the two carts. A milling machine is placed above one of the two drilling units in order to create the pocket. The milling machine is pneumatically operated by means of a brake and its speed can be adjusted to:

quickly reach the slab

perform final cutting.

Return speed is always at the maximum value.

The stroke corresponding to the two speeds can be adjusted by using microswitches. Cutting is aligned with the hole.

Once the slab is positioned, pocket drilling and cutting are automatic. The operator must press the corresponding button to start cutting. Either spindle can be excluded from drilling.

Technical Data

Parameters |

Unit |

Mini |

Pocket position |

Along vertical axis of the hole |

|

Speed adjustment (cont.) |

Regolatore per vel.1 - 2 - 3 |

|

Characteristics |

Holed axis for point cooling/pneumatic operating with hydraulic brake |

|

Stroke adjustment |

Mechanical with backing devices; electric with magnetic sensors |

|

Max. stroke |

mm |

80 |

Speed adjustment (cont.) |

Hydraulic brake for 1 and 2 |

|

Electric motor power |

kW |

2.2 |

Rotation speed |

rpm |

2800 |

Disc max diameter |

mm |

200 |

Speed |

mm/min |

Slow fwd (1) Fast fwd (2) Fast rtn (3) |

Rotation speed |

r/min |

5600 |

Total motor power |

kw |

0.75 |

Speed |

Adjusting device for speeds 1, 2, 3 |

|

Characteristic |

Pneumatic operating with adjusting device |

|

Stroke adjustment |

Mechanical with backing devices; electric with magnetic sensors |

Recommended Stone Drilling, Slot Machine Products

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Stone Drilling Slot Machine

Granite Drilling Slot Machine

Marble Drilling Slot Machine

Limestone Drilling Slot Machine

Onyx Drilling Slot Machine

Basalt Drilling Slot Machine

Quartzite Drilling Slot Machine

Sandstone Drilling Slot Machine

Travertine Drilling Slot Machine

Prometec Machines

Carlo Belle

Carlo Belle