Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesStone Drilling, Slot Machine

CNC Automatic Horizontal Drilling Machine

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesStone Drilling, Slot Machine

Usage:

Granite, Marble, Limestone, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Remote troubleshooting, Field troubleshooting

Machinery Function Features

EQUIPPED WITH

4 horizontal drilling spindles

2 milling machines for pockets

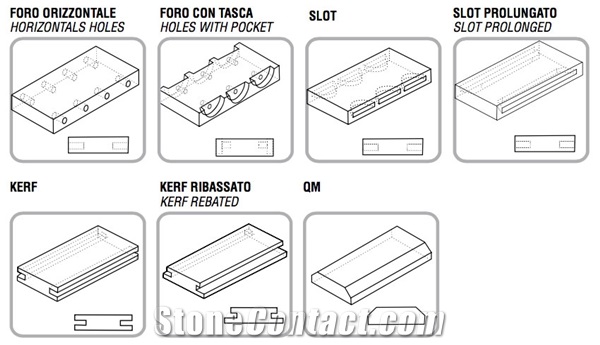

2 horizontal milling machines for slot, stopped slot, prolonged slot, kerf, rebated kerf (with shaped wheel), QM (bevel cut)

The machine features:

2 slab conveyors with manually adjusted width for processing slabs of different sizes. Alongside each conveyor there is a guide to keep the slab aligned

4 drilling units, 2 on each side of the machine, which can travel along the whole length of the machine

2 cutting units for the pocket placed above two drilling units on each side of the machine

2 cutting units for slot/kerf placed above two drilling units on each side of the machine

2 mechanical stops to hold the slab in position during processing.

Work cycle

Processing occurs when the slab is not moving. The two conveyors move the slab to the mechanical stops. Before reaching them, speed is reduced to allow for smooth, precise positioning.

Then, drilling and pocket cutting are performed, or slots and kerfs are made. Once processing is over, the slab is moved backwards, the two mechanical stops retract, and the conveyors bring the slab to the discharge point.

A new slab is placed on the conveyors, and cycle is started again.

Machine specifications:

Slab max width: 180 cm

Slab min width: 25 cm

Max distance between 2 holes: 190 cm

Min distance between 2 holes without milling machine: 18 cm

Min distance between 2 holes with milling machine: 23 cm

Handling

Spindle handilng along the whole length of the machine and of the two carts is operated along precision guides by means of recirculating ball slide guides.

Motion is operated by precision rolled screws with recirculating ball bushes and precision gearboxes. The four spindles and the two carts are operated by brushless motors coupled with precision gearboxes and driven by electronic drivers which are in turn CNC-operated.

Precision in positioning

Precision in positioning is lower than +/- 0.2 mm.

Output

Depending on the material used (marble, tender or hard granite) the typical hole with 6-8 mm diameter and 25-30 mm depth is completed in 20-30 seconds. The distance between two slabs is about 20 cm which entails a motion time of about 20 seconds. Therefore, 4 holes are completed in 40-50 seconds, with an output of 290-360 holes per hour. The average repositioning time is about 5 seconds.

Lubrication

Lubrication of moving parts is centralized and automated. An automated lubrication cycle for periods when the machine is not used is also available.

Positioning system

It is automated thanks to an industrial computer. The operator must set slab width, hole position with reference to the mechanical stops, make requests for holes with or without pocket, and the automatic system will provide the necessary motions for the drilling heads and the carts.

Once the machine is positioned, the automated work cycle is started.

The height of the drilling spindles is adjusted by using a motor-reducer operated by two buttons on the spindle columns.

4 holes on each side of the slab can be made, along with two pockets on one side, as well as slots, prolonged slots, and kerfs.

The computer features also the following utilities:

Generation of drilling programs, storing of the programs by code (brand), list of and changes to the programs (on the machine) sorted by order

Generation of drilling programs, storing of the programs by code (brand), list of and changes to the programs on PC so that they can be later stored in the machine by using a floppy disc, and sorted by order

Displaying of drilling programs

Displaying of machine status (diagnostics)

Automatic synchronising

Storing and displaying of drilled slabs and of the holes made as of a given date (password required) Lubrication cycles for periods when the machine is not used.

4 horizontal drilling spindles

2 milling machines for pockets

2 horizontal milling machines for slot, stopped slot, prolonged slot, kerf, rebated kerf (with shaped wheel), QM (bevel cut)

The machine features:

2 slab conveyors with manually adjusted width for processing slabs of different sizes. Alongside each conveyor there is a guide to keep the slab aligned

4 drilling units, 2 on each side of the machine, which can travel along the whole length of the machine

2 cutting units for the pocket placed above two drilling units on each side of the machine

2 cutting units for slot/kerf placed above two drilling units on each side of the machine

2 mechanical stops to hold the slab in position during processing.

Work cycle

Processing occurs when the slab is not moving. The two conveyors move the slab to the mechanical stops. Before reaching them, speed is reduced to allow for smooth, precise positioning.

Then, drilling and pocket cutting are performed, or slots and kerfs are made. Once processing is over, the slab is moved backwards, the two mechanical stops retract, and the conveyors bring the slab to the discharge point.

A new slab is placed on the conveyors, and cycle is started again.

Machine specifications:

Slab max width: 180 cm

Slab min width: 25 cm

Max distance between 2 holes: 190 cm

Min distance between 2 holes without milling machine: 18 cm

Min distance between 2 holes with milling machine: 23 cm

Handling

Spindle handilng along the whole length of the machine and of the two carts is operated along precision guides by means of recirculating ball slide guides.

Motion is operated by precision rolled screws with recirculating ball bushes and precision gearboxes. The four spindles and the two carts are operated by brushless motors coupled with precision gearboxes and driven by electronic drivers which are in turn CNC-operated.

Precision in positioning

Precision in positioning is lower than +/- 0.2 mm.

Output

Depending on the material used (marble, tender or hard granite) the typical hole with 6-8 mm diameter and 25-30 mm depth is completed in 20-30 seconds. The distance between two slabs is about 20 cm which entails a motion time of about 20 seconds. Therefore, 4 holes are completed in 40-50 seconds, with an output of 290-360 holes per hour. The average repositioning time is about 5 seconds.

Lubrication

Lubrication of moving parts is centralized and automated. An automated lubrication cycle for periods when the machine is not used is also available.

Positioning system

It is automated thanks to an industrial computer. The operator must set slab width, hole position with reference to the mechanical stops, make requests for holes with or without pocket, and the automatic system will provide the necessary motions for the drilling heads and the carts.

Once the machine is positioned, the automated work cycle is started.

The height of the drilling spindles is adjusted by using a motor-reducer operated by two buttons on the spindle columns.

4 holes on each side of the slab can be made, along with two pockets on one side, as well as slots, prolonged slots, and kerfs.

The computer features also the following utilities:

Generation of drilling programs, storing of the programs by code (brand), list of and changes to the programs (on the machine) sorted by order

Generation of drilling programs, storing of the programs by code (brand), list of and changes to the programs on PC so that they can be later stored in the machine by using a floppy disc, and sorted by order

Displaying of drilling programs

Displaying of machine status (diagnostics)

Automatic synchronising

Storing and displaying of drilled slabs and of the holes made as of a given date (password required) Lubrication cycles for periods when the machine is not used.

Technical Data

Parameters |

Unit |

DRILLING UNIT |

HOLE POCKET UNIT |

SLOT/KERF UNIT |

Speed |

mm/min |

Slow fwd (1)Fast fwd 2) Fast rtn (3) |

Slow fwd (1)Fast fwd 2) Fast rtn (3) |

Fast fwd (1) Fast rtn (2) |

Max. stroke |

mm |

80 |

- |

- |

Cutting Groove Diameter |

mm |

- |

200 |

200 |

Rotation speed |

r/min |

5600 |

2800 |

2800 |

Total motor power |

kw |

1.1 |

2.2 |

3.7 |

Stroke adjustment |

Mechanical with backing devices; electronic with magnetic sensors |

Mechanical with backing devices; electronic with magnetic sensors |

Mechanical with backing devices; electronic with magnetic sensors |

|

Max. working thickness |

mm |

- |

- |

6 |

Speed adjustment (cont.) |

Hydraulic brake for 1/2 |

Gearbox for 1, 2, and 3 |

Gearbox for 1 and 2 |

|

Pocket position |

- |

Along the vertical axis of the hole |

- |

|

Characteristics |

Holed axis for point cooling, pneumatic operating with hydraulic brake |

Pneumatic operating with hydraulic brake |

Pneumatic operating with gearbox |

Recommended Stone Drilling, Slot Machine Products

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Stone Drilling Slot Machine

Granite Drilling Slot Machine

Marble Drilling Slot Machine

Limestone Drilling Slot Machine

Artificial Stone Drilling Slot Machine

Basalt Drilling Slot Machine

Quartzite Drilling Slot Machine

Sandstone Drilling Slot Machine

Travertine Drilling Slot Machine

Prometec Machines

Carlo Belle

Carlo Belle