Home ProductsStone MachineryStone Factory MachinesStone Finishing, Profiling MachinesStone Drilling, Slot Machine

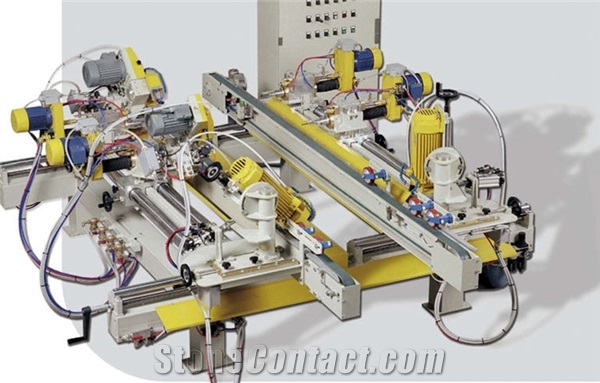

JUNIOR Horizontal Drilling Machine Semi Automatic Slotting/Kerfing/QM

FOB Price:

Type:

Stone Factory MachinesStone Finishing, Profiling MachinesStone Drilling, Slot Machine

Usage:

Granite, Marble, Limestone, Slate, Onyx, Basalt, Quartzite, Sandstone, Travertine

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Remote troubleshooting

Machinery Function Features

EQUIPPED WITH :

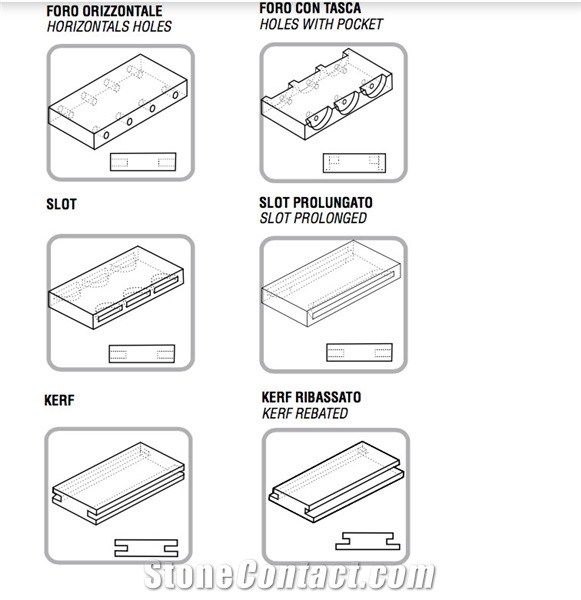

4 drilling units for horizontal holes

2 vertical milling machines for hole pocket

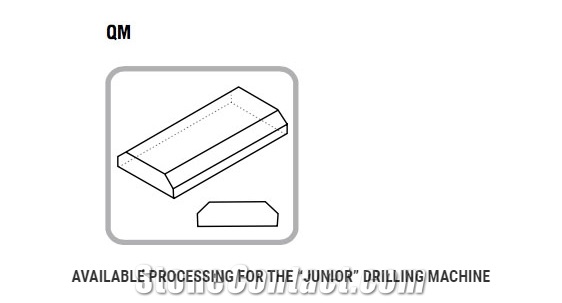

2 horizontal milling machines for slot, stopped slot, prolonged slot, kerf, and rebated kerf (with shaped wheel), QM (bevel cut)

The machine features:

2 slab conveyors with manually adjusted width for processing slabs of different sizes. Alongside each conveyor there is a guide to keep the slab aligned

4 drilling units, 2 on each side of the machine, which can travel along the whole length of the machine

2 cutting units for the pocket placed above two drilling units on each side of the machine

2 cutting units for slot/kerf placed above two drilling units on each side of the machine

2 mechanical stops to hold the slab in position during processing

MACHINE SPECIFICATIONS

Slab max width: 188 cm

Slab min width: 26 cm

Max distance between 2 holes:

160 cm (without vertical milling machines) 130 cm (with vertical milling machines)

Min distance between 2 holes without pocket:20 cm

Slab conveying carts

Slab conveying carts are made up of two traverse beams along which two beams equipped with motor- operated slab conveyors move. The width of each beam can be adjusted to process slabs of different sizes.

The width can be adjusted manually by using a small wheel. The carts move along chrome-plated bars with precision bushes.

Each cart also features a slab guide and an end stop pneumatically operated in order to process the slab when it is not moving (holes and hole pockets).

The back/forth motion of the slab conveyors can be selected from the electric panel.

With forward motion, the slab enters and exits from the opposite end. With backward motion, the processed slab is brought back to its starting point in order to be discharged.

Drilling units

By means of a small wheel, four drilling units, two on each side of the machine, can be manually placed longitudinally on two chrome-plated bars of large diameter the whole length of the machine.

Holes are made when the slab is not moving and held in position by means of two guides and two mechanical stops.

The drilling units are pneumatically operated by means of a hydraulic brake.

Feeding has two speeds:

the first allows for slow penetration of the points into the slab until the points are guided by the hole itself

the second allows for drilling at optimum speed. Return stroke is always at high speed

Return stroke is always at high speed.

One or more spindles can be excluded from processing by selecting them on the operator’s touch screen.

4 drilling units for horizontal holes

2 vertical milling machines for hole pocket

2 horizontal milling machines for slot, stopped slot, prolonged slot, kerf, and rebated kerf (with shaped wheel), QM (bevel cut)

The machine features:

2 slab conveyors with manually adjusted width for processing slabs of different sizes. Alongside each conveyor there is a guide to keep the slab aligned

4 drilling units, 2 on each side of the machine, which can travel along the whole length of the machine

2 cutting units for the pocket placed above two drilling units on each side of the machine

2 cutting units for slot/kerf placed above two drilling units on each side of the machine

2 mechanical stops to hold the slab in position during processing

MACHINE SPECIFICATIONS

Slab max width: 188 cm

Slab min width: 26 cm

Max distance between 2 holes:

160 cm (without vertical milling machines) 130 cm (with vertical milling machines)

Min distance between 2 holes without pocket:20 cm

Slab conveying carts

Slab conveying carts are made up of two traverse beams along which two beams equipped with motor- operated slab conveyors move. The width of each beam can be adjusted to process slabs of different sizes.

The width can be adjusted manually by using a small wheel. The carts move along chrome-plated bars with precision bushes.

Each cart also features a slab guide and an end stop pneumatically operated in order to process the slab when it is not moving (holes and hole pockets).

The back/forth motion of the slab conveyors can be selected from the electric panel.

With forward motion, the slab enters and exits from the opposite end. With backward motion, the processed slab is brought back to its starting point in order to be discharged.

Drilling units

By means of a small wheel, four drilling units, two on each side of the machine, can be manually placed longitudinally on two chrome-plated bars of large diameter the whole length of the machine.

Holes are made when the slab is not moving and held in position by means of two guides and two mechanical stops.

The drilling units are pneumatically operated by means of a hydraulic brake.

Feeding has two speeds:

the first allows for slow penetration of the points into the slab until the points are guided by the hole itself

the second allows for drilling at optimum speed. Return stroke is always at high speed

Return stroke is always at high speed.

One or more spindles can be excluded from processing by selecting them on the operator’s touch screen.

Technical Data

Parameters |

Unit |

Holed axis for point cooling / pneumatic operating by means of hydraulic brakeCorsa |

Pneumatic operating with speed adjusting device |

Cutting Groove Diameter |

mm |

- |

200 |

Max. stroke |

mm |

80 |

- |

Rotation speed |

r/min |

5600 |

2800 |

Speed adjustment (cont.) |

Hydraulic brake for 1/Hydraulic brake for 2 |

Adjusting device for 1, 2, and 3 |

|

Total motor power |

kw |

0.75 |

2.2 |

Stroke adjustment |

Mechanical with backing devices; electric with magnetic sensors |

Mechanical with backing devices; electric with magnetic sensors |

|

Pocket position |

- |

Along the vertical axis of the hole |

|

Speed |

mm/min |

Slow fwd (1) Fast fwd (2) Fast rtn (3) |

Slow fwd (1) Fast fwd (2) Fast rtn (3) |

Recommended Stone Drilling, Slot Machine Products

Related Products:

Machinery

Factory Machines

Stone Finishing Profiling Machines

Stone Drilling Slot Machine

Granite Drilling Slot Machine

Marble Drilling Slot Machine

Limestone Drilling Slot Machine

Slate Drilling Slot Machine

Onyx Drilling Slot Machine

Basalt Drilling Slot Machine

Quartzite Drilling Slot Machine

Sandstone Drilling Slot Machine

Travertine Drilling Slot Machine

Prometec Machines

Carlo Belle

Carlo Belle