Continuous scoring and splitting Machine -NoStop Cut Waterless Processing Machine

FOB Price:

Type:

Artificial Stone MachinesCutting and Splitting Machine

Usage:

Artificial Stone

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

Machinery Function Features

Cutting sizes from 150mm to 3200mm

Splitting sizes from 200mm to 3200mm

Up to 8 powered heads – 6 fixed engraving heads.

Machine to obtain sub-sizes through splitting.

The machine can operate in two modes and meet a wide range of production needs:

Pre-cut + engraving: the tools equipped with discs make partial cuts on the bottom; subsequently, incipient fractures are made on these cuts by means of engraving heads.

Engraving: is carried out only by means of engraving heads so as to make incipient fractures directly onto the original surface of the material. The above operating mode can only be applied to smooth, even surfaces, free of internal tensions.

Pre-cutting and engraving head:

Powered cutting unit with electric spindles with fixture for cutting discs. At the base of each cutting head is mounted a bar with press rolls that hold in line the material during machining, absorbing the stresses transmitted by the tool.

The idle heads have the opportunity to bring two different types of engravers, one with a greater diameter for smooth or one with a smaller diameter, used for efficiently engraving even uneven surfaces.

Roller splitting:

The machine is used to split ceramic slabs along one or more incipient fractures made previously. The slab is split without stopping its forward motion along the line.

The slab, carried by a conveyor belt, passes through 3 cross rollers with independent adjustment systems, placed two above and one below the conveyor belt to create a condition of interference which causes the rupture along the incipient fracture lines.

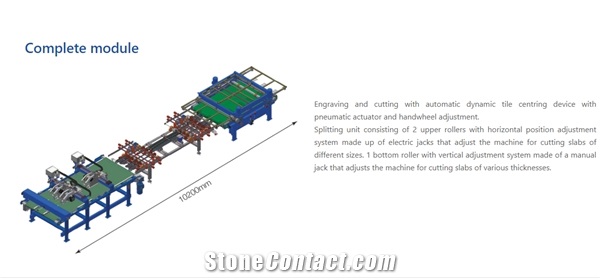

Engraving and cutting with automatic dynamic tile centering device with pneumatic actuator and handwheel adjustment.

Splitting unit consisting of 2 upper rollers with horizontal position adjustment system made up of electric jacks that adjust the machine for cutting slabs of different sizes. 1 bottom roller with vertical adjustment system made of a manual jack that adjusts the machine for cutting slabs of various thicknesses.

Splitting sizes from 200mm to 3200mm

Up to 8 powered heads – 6 fixed engraving heads.

Machine to obtain sub-sizes through splitting.

The machine can operate in two modes and meet a wide range of production needs:

Pre-cut + engraving: the tools equipped with discs make partial cuts on the bottom; subsequently, incipient fractures are made on these cuts by means of engraving heads.

Engraving: is carried out only by means of engraving heads so as to make incipient fractures directly onto the original surface of the material. The above operating mode can only be applied to smooth, even surfaces, free of internal tensions.

Pre-cutting and engraving head:

Powered cutting unit with electric spindles with fixture for cutting discs. At the base of each cutting head is mounted a bar with press rolls that hold in line the material during machining, absorbing the stresses transmitted by the tool.

The idle heads have the opportunity to bring two different types of engravers, one with a greater diameter for smooth or one with a smaller diameter, used for efficiently engraving even uneven surfaces.

Roller splitting:

The machine is used to split ceramic slabs along one or more incipient fractures made previously. The slab is split without stopping its forward motion along the line.

The slab, carried by a conveyor belt, passes through 3 cross rollers with independent adjustment systems, placed two above and one below the conveyor belt to create a condition of interference which causes the rupture along the incipient fracture lines.

Engraving and cutting with automatic dynamic tile centering device with pneumatic actuator and handwheel adjustment.

Splitting unit consisting of 2 upper rollers with horizontal position adjustment system made up of electric jacks that adjust the machine for cutting slabs of different sizes. 1 bottom roller with vertical adjustment system made of a manual jack that adjusts the machine for cutting slabs of various thicknesses.

Stefano Baraldi

Stefano Baraldi