Home ProductsStone MachineryStone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

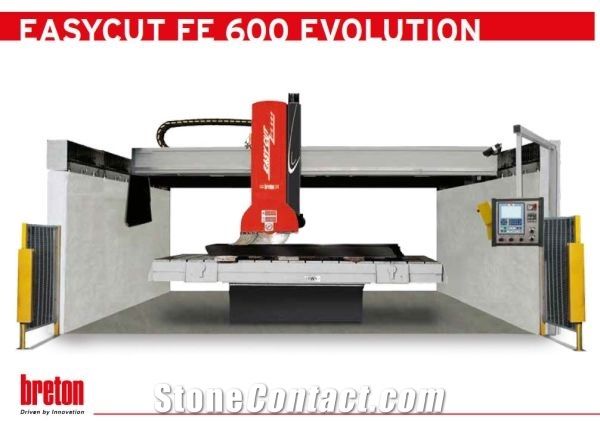

Breton Easycut FE 600 Evolution Bridge Saw

FOB Price:

Type:

Stone Factory MachinesStone Slab Cutting MachinesCNC Bridge Cutting Machine

Usage:

Granite, Marble, Limestone

After-Sale

Warranty:12 Months

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

Maintenance:Online software upgrade, Regular guidance & maintenance, Remote troubleshooting, Field troubleshooting

Trade Terms

Delivery Details: FOB

Payment :

Supplier

Breton S.p.A.

Italy

Italy

Eatablished :Dec 31,1962

Main Product:

Stone Machines, Cutting Machine, Polising Machine, Wire Saw, Cnc Machines|

Contact supplier

You may also like

Machinery Function Features

EASYCUT FE 600 EVOLUTION - SIMPLE, PRECISE AND STURDY BRIDGE SAW

Simple, precise and sturdy bridge saw, ideal for the most frequent processing.

Do you want to know everything about the new bridge saw EASYCUT FE 600 EVOLUTION?

Equipped with ø 625mm circular blade, manually inclinable in any position from 0° to 90°, with possibility of step-cutting, even inclined.

- Mobile button panel with 7" colour touch-screen, that can be transferred inside the working area for the alignment of the beam with the cut-tracing laser; it also allows to store up to 100 different sequences of longitudinal cuts, programmable at will; the button panel is prearranged to operate using both millimetres and inches.

- Joysticks to move the machine axes when performing manual cuts.- Simultaneous movement of the X-Y axes, which are controlled by inverter and encoder.

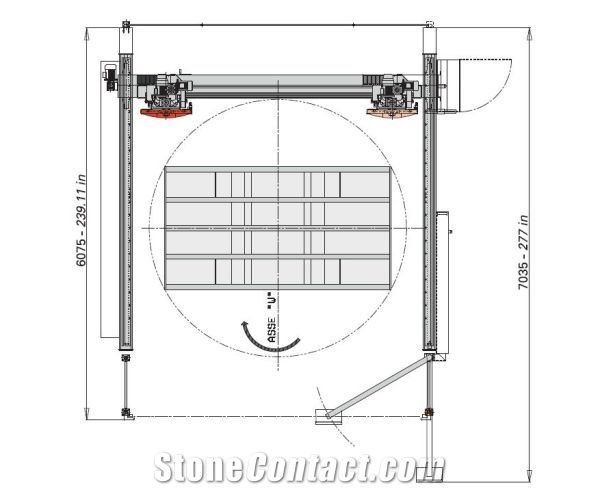

- Work bench provided with manual rotation, mechanical locking with pin at 0, 45°, 90° and -45°, and manually actuated mechanical locking in any position from 0 to 360°. The table top is wood-panelled.

The planarity tolerance of the steel worktop (in the different positions) is ± 1 mm with respect to the nominal height.

- Laser unit with continuous beam to drive the cut.

MANY ACCESSORIES AVAILABLE:

- tilting work-table;

- motorized rotation of the worktable;

- optoelectronic drawing copying device which directly reads the profile shape;

- profile/polygon importer enabling to manage DXF files and transferred them to the machine through a SD card.

BASIC SOFTWARE OF EASYCUT FE 600 EVOLUTION BRIDGE SAW ENABLES THE FOLLOWING OPERATIONS:

- Manual cutting of rectangular or polygonal pieces

The machine operating in manual mode is very simple, rapid, intuitive and easy to ap-proach even for non-experienced operators which have no knowledge in electronics. The operator runs the machine using the simple portable button panel and the cut-tracing laser, while reading the cutting depth displayed on the touch-screen.

- Cutting of repetitive rectangular pieces (such as floor tiles)

In this mode, the machine performs automatically a series of longitudinal cuts (each cut can be set at the desired distance), the table is manually rotated by 90°, then the machine proceeds with the transversal cuts (each cut can be set at the desired distance).

- Management of profiles

In this mode, it is possible to draw the desired profile directly on the machine by entering both the rough-machining and finishing parameters. In the machining stage, the position of the saw blade will be the origin the profile.

- Management of polygons

In this mode, it is possible to draw the piece to be realized directly on the machine. In the machining stage, the position of the saw blade will be the origin the profile. This operation can be performed only if the machine is provided with the accessory "motorized rotation of the work bench".

Simple, precise and sturdy bridge saw, ideal for the most frequent processing.

Do you want to know everything about the new bridge saw EASYCUT FE 600 EVOLUTION?

Equipped with ø 625mm circular blade, manually inclinable in any position from 0° to 90°, with possibility of step-cutting, even inclined.

- Mobile button panel with 7" colour touch-screen, that can be transferred inside the working area for the alignment of the beam with the cut-tracing laser; it also allows to store up to 100 different sequences of longitudinal cuts, programmable at will; the button panel is prearranged to operate using both millimetres and inches.

- Joysticks to move the machine axes when performing manual cuts.- Simultaneous movement of the X-Y axes, which are controlled by inverter and encoder.

- Work bench provided with manual rotation, mechanical locking with pin at 0, 45°, 90° and -45°, and manually actuated mechanical locking in any position from 0 to 360°. The table top is wood-panelled.

The planarity tolerance of the steel worktop (in the different positions) is ± 1 mm with respect to the nominal height.

- Laser unit with continuous beam to drive the cut.

MANY ACCESSORIES AVAILABLE:

- tilting work-table;

- motorized rotation of the worktable;

- optoelectronic drawing copying device which directly reads the profile shape;

- profile/polygon importer enabling to manage DXF files and transferred them to the machine through a SD card.

BASIC SOFTWARE OF EASYCUT FE 600 EVOLUTION BRIDGE SAW ENABLES THE FOLLOWING OPERATIONS:

- Manual cutting of rectangular or polygonal pieces

The machine operating in manual mode is very simple, rapid, intuitive and easy to ap-proach even for non-experienced operators which have no knowledge in electronics. The operator runs the machine using the simple portable button panel and the cut-tracing laser, while reading the cutting depth displayed on the touch-screen.

- Cutting of repetitive rectangular pieces (such as floor tiles)

In this mode, the machine performs automatically a series of longitudinal cuts (each cut can be set at the desired distance), the table is manually rotated by 90°, then the machine proceeds with the transversal cuts (each cut can be set at the desired distance).

- Management of profiles

In this mode, it is possible to draw the desired profile directly on the machine by entering both the rough-machining and finishing parameters. In the machining stage, the position of the saw blade will be the origin the profile.

- Management of polygons

In this mode, it is possible to draw the piece to be realized directly on the machine. In the machining stage, the position of the saw blade will be the origin the profile. This operation can be performed only if the machine is provided with the accessory "motorized rotation of the work bench".

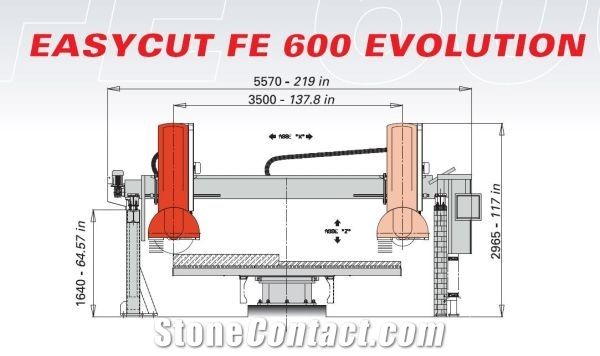

Technical Data

Parameters |

Unit |

Easycut FE 600 Evolution |

F800 |

FK/NC 800 |

FK/NC Optima |

FK/NC 1100 |

Max.length of the cut slab |

mm |

3000 |

3000 |

3000 |

3000 |

3000 |

Max.width of the cut slab |

mm |

1500 |

1500 |

1500 |

1500 |

1500 |

Head raising/lowering stroke(Z axis travel) |

mm |

320 |

320 |

320 |

320 |

320 |

Number of vertical cutting spindles |

nr |

1 |

1 |

1 |

1 |

1 |

Transversal stroke speed (Y displacement speed) |

m/min |

0 ÷ 16 |

0 ÷ 16 |

0 ÷ 16 |

0 ÷ 16 |

0 ÷ 16 |

C axis blade rotation |

° |

90 |

90 |

90 |

90 |

90 |

Horizontal stroke speed(X axis displacement speed) |

m/min |

0 ÷ 16 |

0 ÷ 16 |

0 ÷ 16 |

0 ÷ 16 |

0 ÷ 16 |

Horizontal stroke(X axis travel) |

mm |

3500 |

3500 |

3500 |

3500 |

3500 |

Machine width |

mm |

6000 |

6000 |

6000 |

6000 |

6000 |

Approximate weight without table |

kg |

4500 |

4500 |

4500 |

4500 |

4500 |

Head motor power |

kW |

15 |

25 |

25 |

25 |

33 |

Average level of equivalent sound pressure |

dbA |

84 |

84 |

84 |

84 |

84 |

Machine length |

mm |

5600 |

5600 |

5600 |

5600 |

5600 |

Dimensions of the work table(L×W) |

mm |

3000 x 1500 |

3000 x 1500 |

3000 x 1500 |

3000 x 1500 |

3000 x 1500 |

Bridge transversal stroke(Y axis travel) |

mm |

3600 |

3600 |

3600 |

3600 |

3600 |

Machine height |

mm |

3000 |

3000 |

3000 |

3000 |

3000 |

Vertical stroke speed (Z displacement speed) |

m/min |

0 ÷ 0,9 |

0 ÷ 0,9 |

0 ÷ 0,9 |

0 ÷ 0,9 |

0 ÷ 0,9 |

Max. workable thickness(with 1200mm blade) |

mm |

205 |

225 |

225 |

225 |

300 |

Disc diameter |

mm |

625 |

800 |

800 |

800 |

1100 |

Recommended CNC Bridge Cutting Machine Products

Stefano Titotto

Stefano Titotto